Preparation method of preparation for radioactive gas purifying capability test in nuclear power plant

A technology of radioactive gas and purification ability, applied in chemical instruments and methods, halogenated hydrocarbon preparation, organic chemistry, etc., can solve problems such as management risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

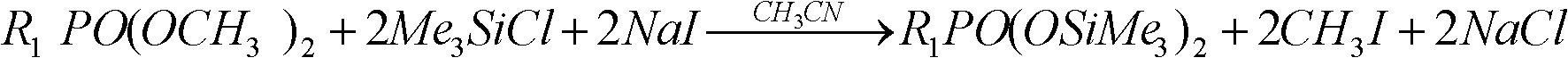

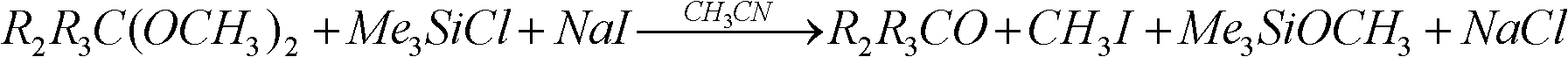

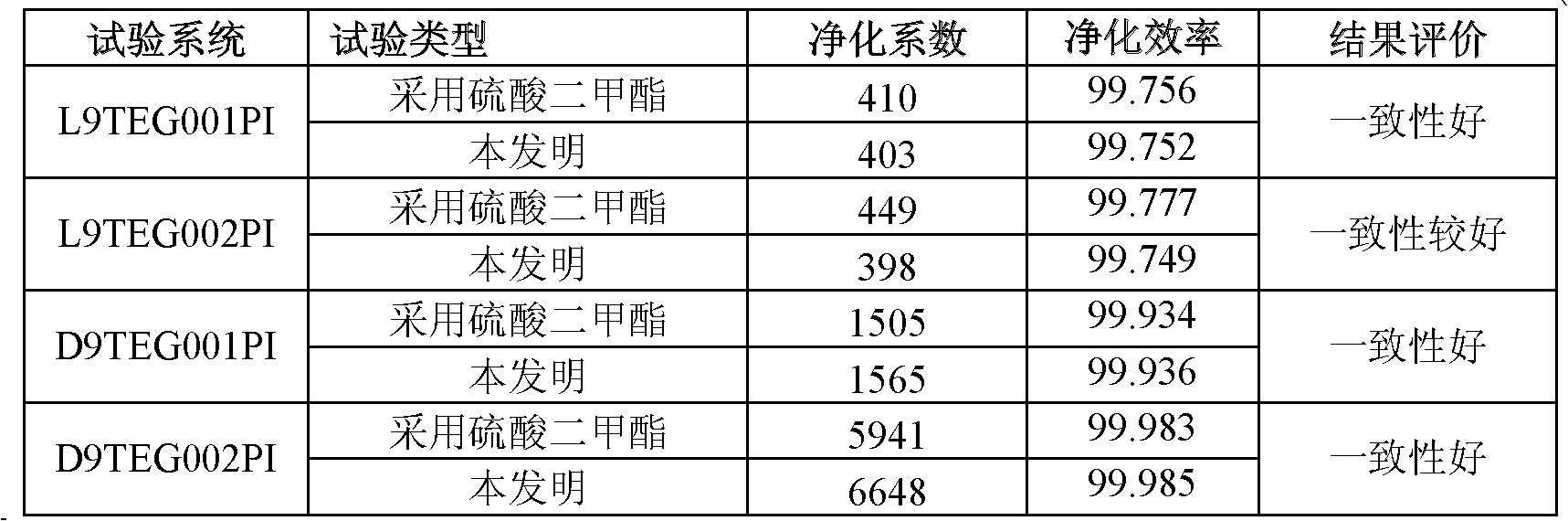

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, put into 8ml acetonitrile, 5g non-radioactive potassium iodide successively in 50ml round bottom reaction flask, wherein non-radioactive potassium iodide is used for simulating radioactive iodine source (the same below, the following examples will not repeat them), then put 2.5ml acetonitrile Dimethylphosphorylacetate and 3.8ml trimethylchlorosilane were mixed evenly, and reacted under magnetic stirring. The reaction temperature was 30°C, and the reaction time was 15min. The yield of non-radioactive methyl iodide in the liquid is about 46% through density analysis.

Embodiment 2

[0035] Example 2, in a 50ml round bottom reaction flask, put 10ml of acetonitrile, 5g of non-radioactive potassium iodide in sequence, then put in 2.75ml of dimethyl o-chlorophenyl phosphate, 3.8ml of trimethylchlorosilane and mix evenly, under magnetic stirring The reaction was carried out at a reaction temperature of 25 °C and a reaction time of 10 min. The non-radioactive methyl iodide was collected by reflux condensation at 70 °C for 1.5 h, and the yield of non-radioactive methyl iodide was about 55% by gas chromatography analysis.

Embodiment 3

[0036] Embodiment 3, put 10ml acetonitrile, 5g non-radioactive sodium iodide successively in 50ml round bottom reaction flask, then put into about 3ml CCl 3 PO(OCH 3 ) 2 , mix about 4ml trimethylchlorosilane, react under magnetic stirring, the reaction temperature is 25°C, the reaction time is 15min, reflux and condense at 70°C to collect non-radioactive methyl iodide for 1.5h, and analyze the non-radioactive methyl iodide by gas chromatography The yield of iodine is about 51%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com