Nuclear safety grade 316L stainless steel gauge pipe

A stainless steel and instrument tube technology, applied in the field of metal smelting, to achieve the effects of optimizing process parameters, simplifying deformation passes, and excellent surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

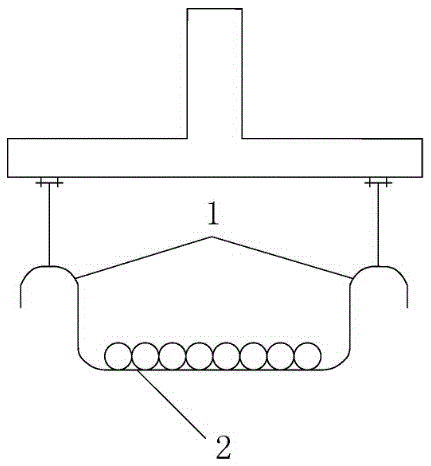

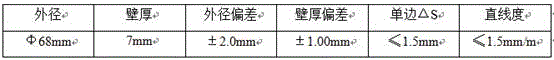

[0029] Example 1: Using 316L stainless steel billet / steel ingot as raw material, a blank pipe is formed by extrusion, and the specification, dimensional deviation and straightness requirements of the blank pipe after finishing are shown in Table 1. 100% visual inspection of the surface of the extruded waste tube requires: the end should be straight and free of burrs, no scale, glass lubricant particles and other impurities are allowed on the inner and outer surfaces, and under-acid, over-acid, stains and rust spots.

[0030] Table 1. Extruded blank pipe specifications, dimensional deviation and straightness requirements

[0031]

[0032] The technical implementation scheme of the cold rolling process is shown in Table 2.

[0033] Table 2. Implementation scheme of cold rolling process

[0034]

[0035] Among them, the billet cold rolling feed is 3.0 mm / n, and the rolling speed is 70 times / min; the finished cold rolling feed is 1.5 mm / n, and the rolling speed is 120 time...

Embodiment 2

[0043] Embodiment 2: The difference between embodiment 2 and embodiment 1 is that the cold rolling feed of the billet is 2.0mm / n, and the rolling speed is 60 times / min; the cold rolling feed of the finished product is 2.0mm / n, and the rolling speed 150 times / min.

[0044] There are five heating zones in the bright furnace, in which zone 1 is set at a temperature of 1010°C; zone 2~4 is set at a temperature of 1060°C; zone 5 is set at a temperature of 1010°C, and the feed rate is 600mm / min. Control the flow rate of hydrogen to 50m 3 / h, the dew point of hydrogen is controlled at -40°C, and the micro-oxygen content of hydrogen does not exceed 15ppm. The cooling time from 900~500℃ is only no more than 3.0 minutes.

[0045] The composition of a 316L stainless steel pipe used for instrumentation pipes is: C: 0.015%, Si: 0.5%, Mn: 1.0%, P: 0.03%, S: 0.005%, Cr: 18.0%, Ni: 12.0 %, Mo: 2.5%, Co: 0.05%, and the balance is Fe.

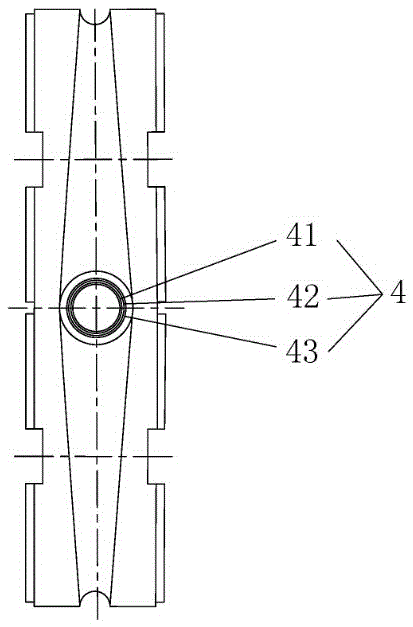

[0046] The cold-rolling mandrel used in the cold-rollin...

Embodiment 3

[0047] Embodiment 3: The difference between embodiment 3 and embodiment 1 is that the cold rolling feed of the billet is 4.0mm / n, and the rolling speed is 80 times / min; the cold rolling feed of the finished product is 1.0mm / n, and the rolling speed 100 times / min.

[0048] There are five heating zones in the bright furnace, in which zone 1 is set at a temperature of 1020°C; zone 2~4 is set at a temperature of 1070°C; zone 5 is set at a temperature of 1020°C, and the feed rate is 600mm / min. Control the flow rate of hydrogen to 70m 3 / h, the dew point of hydrogen is controlled at -60°C, and the micro-oxygen content of hydrogen does not exceed 15ppm. The cooling time from 900~500℃ is only no more than 1.0 minutes.

[0049] The composition of a 316L stainless steel pipe used for instrumentation pipes is: C: 0.04%, Si: 0.12%, Mn: 2.0%, P: 0.02%, S: 0.010%, Cr: 16.0%, Ni: 14.0 %, Mo: 2.0%, Co: 0.01%, and the balance is Fe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com