Modification method for filter material used in filter core of nuclear grade water filter

A water filter and filter material technology, which is applied in the field of modification of filter materials used in nuclear-grade water filter elements, can solve problems such as unsatisfactory, and achieve the effect of improving filtration efficiency and improving leaching resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

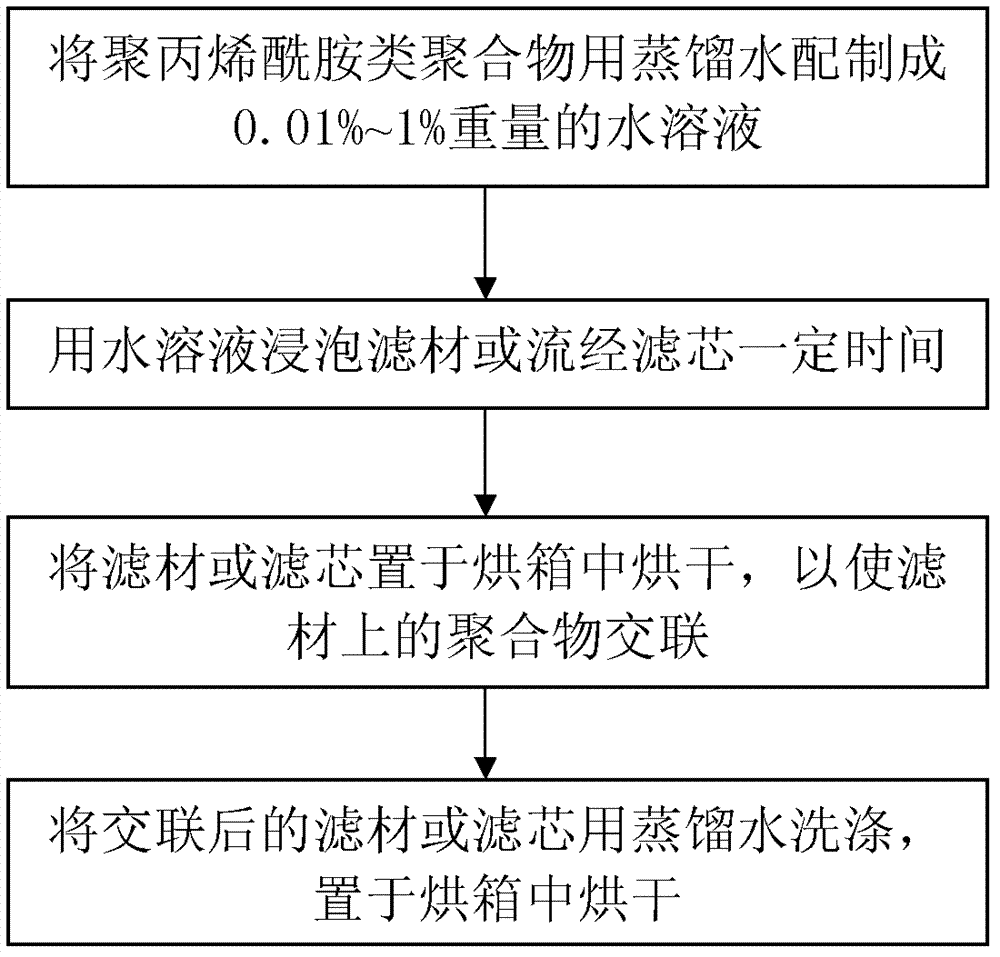

[0025] The method for modifying the filter material used in the filter element of the nuclear-grade water filter comprises the following steps:

[0026] (1) the chitosan modified polyacrylamide polymer is formulated with distilled water as an aqueous solution with a mass concentration of 1%;

[0027] (2) soak glass fiber filter material 10h with the aqueous solution described in step (1);

[0028] (3) Place the soaked filter material in an oven and dry at 30°C to cross-link the polymer on the filter material;

[0029] (4) Wash the cross-linked filter material with distilled water, dry it in an oven at 30° C., and set it aside.

Embodiment 2

[0031] The method for modifying the filter material used in the filter element of the nuclear-grade water filter comprises the following steps:

[0032] (1) the copolymer of acrylamide and ethyl acrylate trimethyl ammonium chloride is mixed with distilled water and is the aqueous solution of 0.01% in mass concentration;

[0033] (2) with the aqueous solution described in step (1), flow through filter core 30min, the material of filter core is glass fiber filter material;

[0034] (3) place the filter element after flowing through in an oven and dry at 120° C., so that the polymer on the filter element filter material is cross-linked;

[0035] (4) Wash the cross-linked filter element with distilled water, dry it in an oven at 50° C., and set it aside.

Embodiment 3

[0037] The method for modifying the filter material used in the filter element of the nuclear-grade water filter comprises the following steps:

[0038] (1) Cationic polyamide epichlorohydrin polymer is mixed with distilled water and is the aqueous solution of 0.4% in mass concentration;

[0039] (2) Soak the paper filter material with the aqueous solution described in step (1) for 24h;

[0040] (3) Place the soaked filter material in an oven and dry at 80°C to cross-link the polymer on the filter material;

[0041] (4) Wash the cross-linked filter material with distilled water, dry it in an oven at 40° C., and set it aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com