Curing treatment additive, curing formula and process for radioactive boron-containing waste liquid

A solidification treatment and radioactive technology, applied in the field of solidification treatment additives for radioactive boron-containing waste liquid, can solve the problems of undisclosed key points of the technical solution, prone to crystallization, loose structure, etc., achieve good volume reduction effect and improve compression resistance Strength, fluidity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

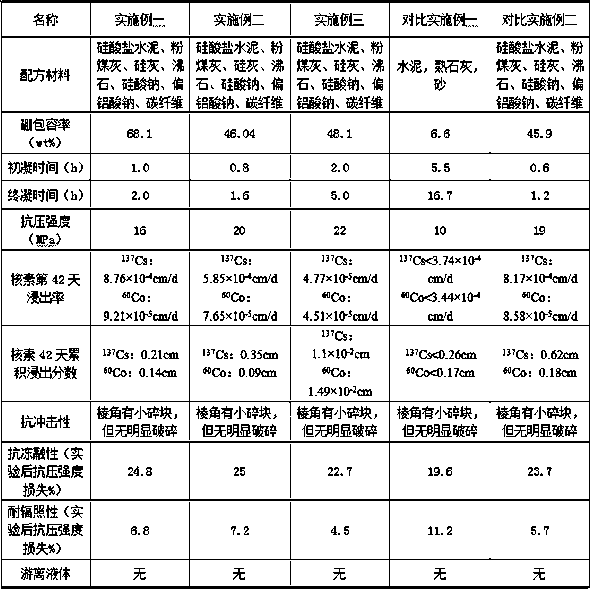

Examples

Embodiment 1

[0031] a. The addition ratio of polymeric borate solution and curing agent in this formula is 28:9. Configure 280g of polymerized borate solution (boron concentration 160000mg / kg, use 252.51g of boric acid), 60g of cement, 15g of fly ash, 5g of silica fume, 5g of zeolite, 2.5g of sodium metaaluminate, 2.5g of sodium silicate, carbon fiber powder 1g.

[0032] b. Mixing materials: Add the curing agent into the polymerized borate solution, and stir for 10 minutes with a mixer at a speed of 500 r / min.

[0033] c. Grouting: Pour the stirred cement slurry into the curing bucket and let it cool naturally.

Embodiment 2

[0035]a. The addition ratio of polymeric borate solution and curing agent in this formula is 28:20. Prepare 280g of polymerized borate solution (boron concentration 140000mg / kg, use 221.92g of boric acid), 100g of cement, 60g of fly ash, 15g of silica fume, 15g of zeolite, 5g of sodium metaaluminate, 5g of sodium silicate, and 2g of carbon fiber powder.

[0036] b. Mixing materials: Add the curing agent into the polymerized borate solution, and stir for 10 minutes with a mixer at a speed of 500 r / min.

[0037] c. Grouting: Pour the stirred cement slurry into the curing bucket and let it cool naturally.

Embodiment 3

[0039] a. The addition ratio of polymeric borate solution and curing agent in the formulation of this research is 25:16. Configure 500g of polymerized borate solution (boron concentration 140000mg / kg, use boric acid 394.55g), Portland cement 140g, fly ash 120g, silica fume 25g, zeolite 25g, sodium metaaluminate 5g, sodium silicate 5g, carbon fiber Powder 2g.

[0040] b. Mixing materials: Add the curing agent into the polymerized borate solution, and stir for 10 minutes with a mixer at a speed of 500 r / min.

[0041] c. Grouting: Pour the stirred cement slurry into the curing bucket and let it cool naturally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com