A cement solidified body of nuclear power plant radioactive distillation residue and its preparation method

A cement curing and radioactive technology, applied in radioactive purification, nuclear engineering and other directions, can solve the problems of slow setting time, large capacity expansion rate, and rapid loss of fluidity over time, so as to reduce hydration heat release and accelerate fluidity loss. , The effect of improving the capillary structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

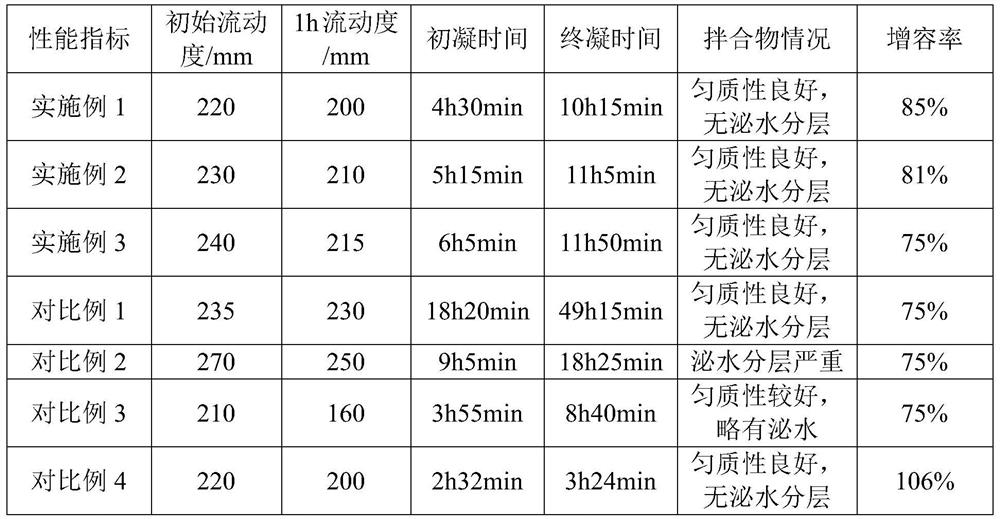

Examples

preparation example Construction

[0025] The preparation process of embodiment 1~5 is as follows:

[0026] A. Prepare curing special additives according to mass percentage;

[0027] B. The solidification special additive and cement obtained in A are loaded into the hopper successively, the special solidification additive for controlling is located at the lower floor, and the cement is located at the upper floor;

[0028] C. Prepare the simulated steamed residue and pour it into the solidified steel drum, insert the stirring paddle, and stir at a constant speed of 300r / min;

[0029] D. Open the hopper of step B, and slowly and uniformly add the mixed material into the solidified steel drum at a speed of 80r / min within 20min;

[0030] E. Increase the stirring speed of the stirring paddle to 120r / min, continue to accelerate the stirring for 25 minutes, and then pull out the stirring paddle;

[0031] F. Cover the steel drum and maintain it at room temperature to obtain the cement solidified body of the radioacti...

Embodiment 1

[0033] Mix mineral powder, diatomaceous earth, zeolite powder, starch ether, and powdered polycarboxylate superplasticizer according to the mass percentage of 60%: 17.6%: 20%: 0.4%: 2% to form a special curing additive. Water, Boric acid, mannitol, and sodium hydroxide are prepared by mass percentage 93%: 5%: 1%: 1% to prepare the simulated steamed raffinate, and the simulated steamed raffinate, cement and special curing additives are used in a mass ratio of 4:7:3 according to the above steps Stir to prepare the steam raffinate cement solidified body.

Embodiment 2

[0035] Mix mineral powder, diatomaceous earth, zeolite powder, starch ether, and powdered polycarboxylate superplasticizer according to the mass percentage of 50%: 31.7%: 15%: 0.3%: 3% to form a special curing additive, water, Boric acid, mannitol, and sodium hydroxide are prepared according to the mass percentage of 95.1%: 3.5%: 0.8%: 0.6% to prepare the simulated steamed raffinate, and the simulated steamed raffinate, cement and special curing additives are used according to the mass ratio of 1.68:3:1 according to the above steps Stir to prepare the steam raffinate cement solidified body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com