Method for solidifying radioactive solid waste cement

A technology of radioactive waste and cement solidification, applied in radioactive purification, nuclear engineering and other directions, can solve the problems of unmeasured leaching performance and no improvement, and achieve the improvement of anti-leaching performance, improving anti-leaching performance and strength, and improving treatment effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

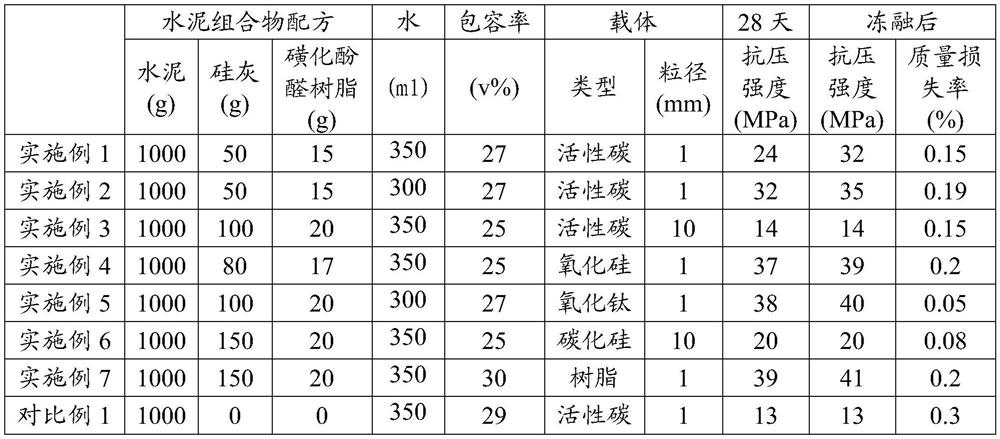

Embodiment 1

[0044] Mix 1000g of ordinary Portland cement, 50g of silica fume and 15g of sulfonated phenolic resin uniformly, pour 350ml of water into the stirring pot, and then mix the uniformly mixed material and 200ml of radioactive catalyst (activated carbon carrier, active component Ru, active The mass fraction of the components is 3%, and the particle size is 1 mm) into a stirring pot and stirred for about 4 minutes. The volume of the cement slurry was measured, and the volume inclusion rate of the available catalyst was 27v%.

[0045] Pour the mixed cement slurry into the mold and put it into the curing box. The curing temperature is 25±5°C, the humidity is greater than 90%, and the cured body is made after curing for 28 days.

Embodiment 2

[0047] Mix 1000g of ordinary Portland cement, 50g of silica fume and 15g of sulfonated phenolic resin evenly, pour 300ml of water into the stirring pot, and then mix the well-mixed dry powder and 200ml of radioactive catalyst (activated carbon carrier, active component Pt, The mass fraction of active components is 5%, and the particle size is 1 mm) into a stirring pot and stirred for about 4 minutes. The volume of the cement slurry was measured, and the volume inclusion rate of the available catalyst was 27v%. Subsequent operations are the same as in Example 1.

Embodiment 3

[0049] Mix 1000g of ordinary Portland cement, 100g of silica fume and 20g of sulfonated phenolic resin evenly, pour 350ml of water into the stirring pot, and then mix the well-mixed dry powder and 200ml of radioactive catalyst (activated carbon carrier, active component Ru / Pt, active component mass fraction of 5%, particle size of 10 mm) was poured into a stirring pot and stirred for about 4 minutes. The volume of the cement slurry was measured, and the volume inclusion rate of the available catalyst was 25v%. Subsequent operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com