Preparation method of low-viscosity potato octenyl succinic acid starch ester

A technology of octenyl succinic acid and potato starch, applied in the field of preparation of octenyl succinate starch ester, can solve the problems of high viscosity microcapsule wall material and the like of octenyl succinate potato starch ester, achieve excellent hydrophobicity, Good fluidity, the effect of improving emulsification characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

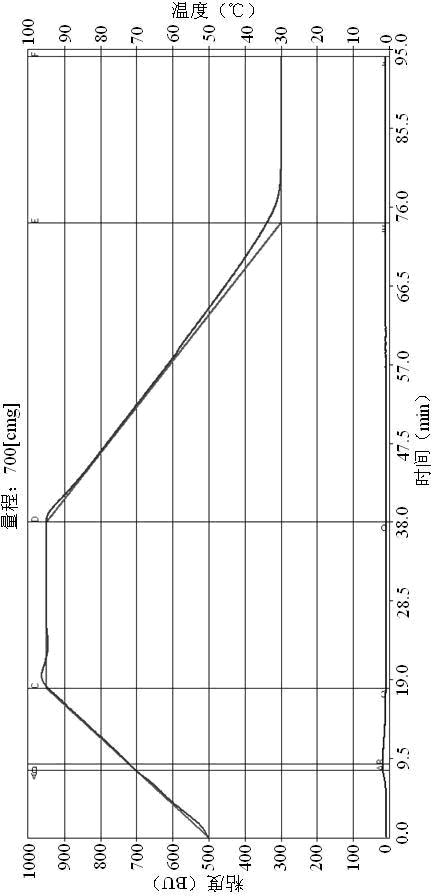

Image

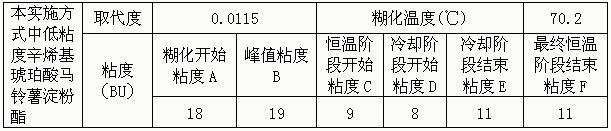

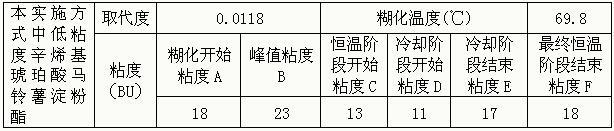

Examples

specific Embodiment approach 1

[0007] Specific embodiment one: the preparation method of low-viscosity potato starch octenyl succinate in the present embodiment is carried out according to the following steps: one, take by weighing potato refined starch, add ultrapure water and stir, potato starch dry base The mass ratio to pure water is 2:3, then add concentrated hydrochloric acid to make the concentration of HCl in the reaction system 0.78~0.8mol / L, then acidolysis reaction in a constant temperature water bath at 45~50℃ for 2.5~3h, and then use the mass concentration Adjust the pH value of 1.8%~2% sodium hydroxide solution to 6.50~7.00, then wash with deionized water until no chloride ions appear in the washing liquid, then add ultrapure water and stir well to obtain starch milk, wherein starch milk The dry basis mass content of potato starch in medium is 39%~40%; 2. Under the conditions of 33~35°C and pH value of 7.50±0.05, add octenyl with a mass concentration of 3% to the starch milk dropwise within 1.5...

specific Embodiment approach 2

[0009] Specific embodiment 2: This embodiment differs from specific mode 1 in that: the mass concentration of the concentrated hydrochloric acid described in step 1 is 35%-37%. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 3, the drying temperature is 50° C., and the drying time is 3-5 hours. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com