Alkaline environmental-friendly zinc-plating additive for changing cyanogen process into cyanogen-free process

A galvanizing additive and alkaline technology, applied in the field of brightening additives, can solve the problems of narrow current range, difficult to obtain coating, poor throwing ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

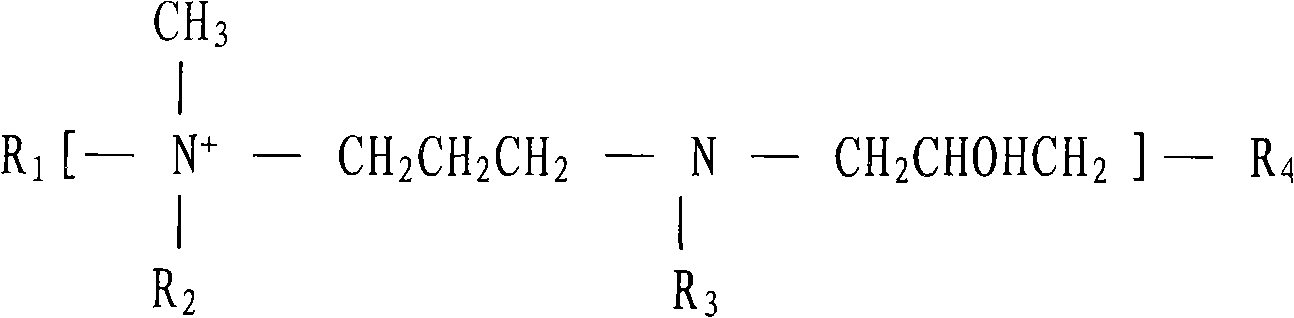

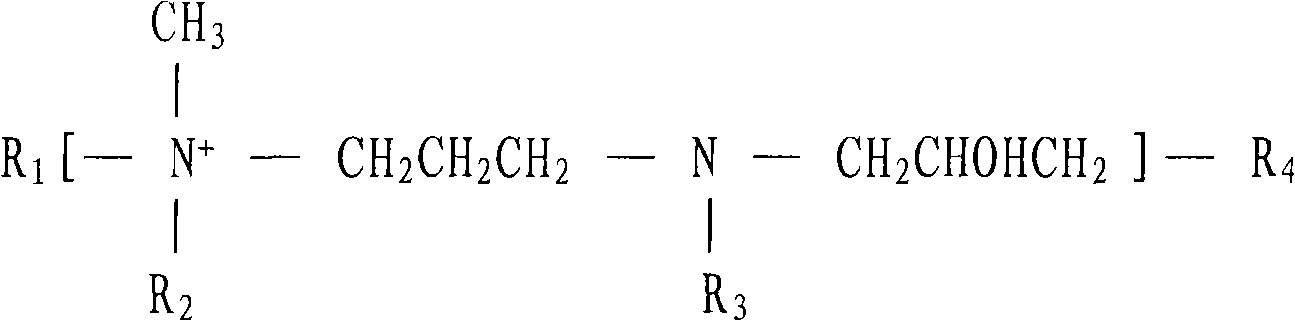

Method used

Image

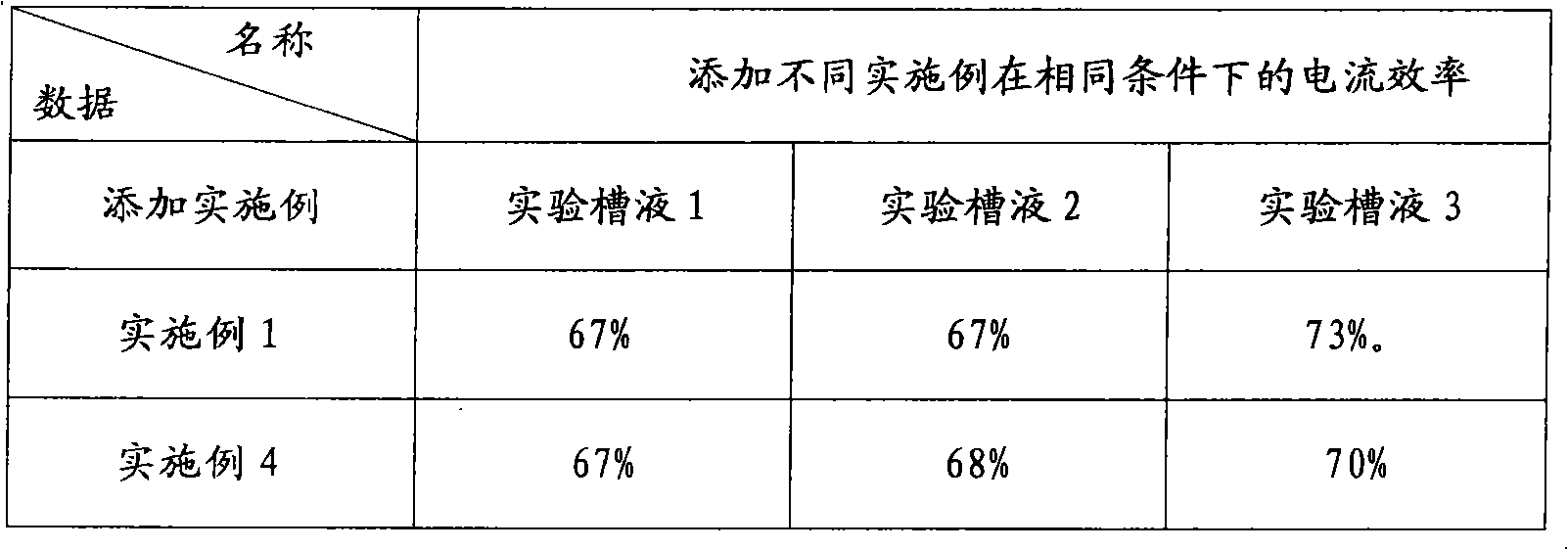

Examples

Embodiment 1

[0028] N-Methylimidazole: 5g / L

[0029] Polycondensate of dimethylaminopropylamine, ethylenediamine and epichlorohydrin: 10g / L

[0030] Add appropriate amount of water into the reactor, and under stirring, add the raw materials at 5g / L of N-methylimidazole and 10g / L of the polycondensate of dimethylaminopropylamine, ethylenediamine and epichlorohydrin into the reactor. Stir well and pack.

Embodiment 2

[0032] 2,2-Bipyridine: 20g / L

[0033] Polycondensate of dimethylaminopropylamine and epoxy epichlorohydrin: 2.5g / L

[0034] Add an appropriate amount of water to the reaction kettle. Under stirring, add the raw materials at 20g / L of 2,2-bipyridine and 2.5g / L of the polycondensate of dimethylaminopropylamine and epoxy epichlorohydrin into the reaction kettle. Stir well and pack.

Embodiment 3

[0036] Indole 6g / L, 2-methylindole 4g / L

[0037] Polycondensate of dimethylamine and epoxy epichlorohydrin: 15g / L

[0038] Add an appropriate amount of water to the reactor, and under stirring, add the raw materials at 6g / L indole, 4g / L 2-methylindole, and 15g / L polycondensate of dimethylamine and epichlorohydrin to the reaction. In the kettle, stir well and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com