Whirl pulverized coal burner used for industrial stove and adopting gas recirculation

A flue gas recirculation and pulverized coal burner technology, which is applied in the direction of burners, burners, and combustion methods for burning powder fuels, can solve the problems of large NOx emissions, reduce flame temperature, and suppress fuel-type NOx Production, the effect of suppressing the production of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

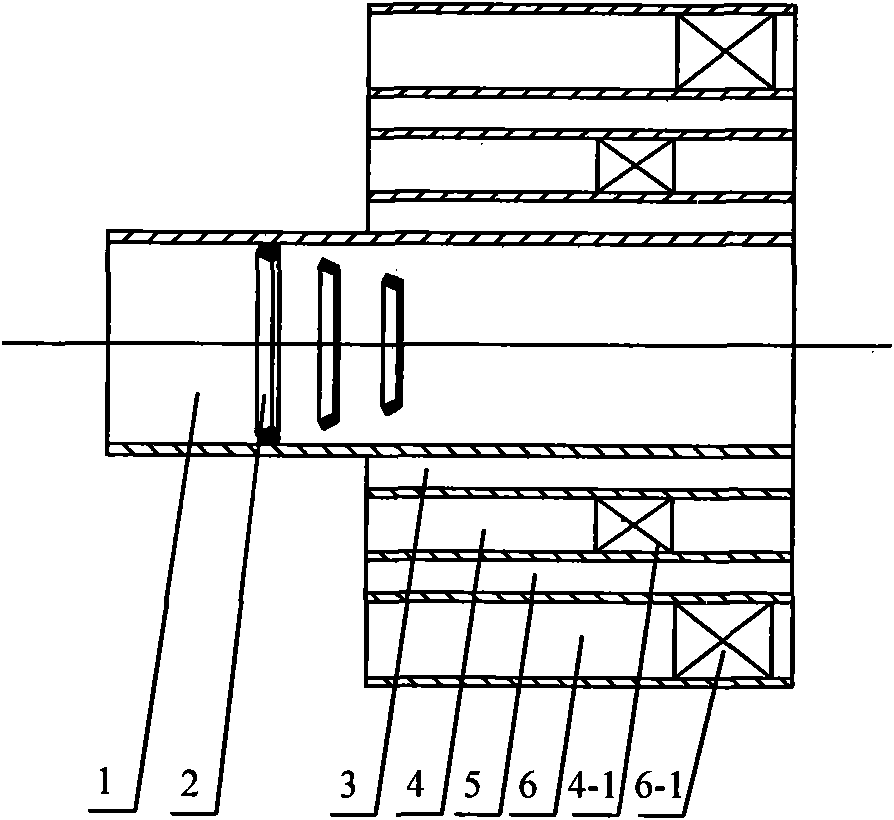

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, the pulverized coal burner of this embodiment comprises primary air channel 1, inner secondary air channel 4, inner secondary air swirler 4-1, outer secondary air channel 6 and outer secondary air swirl device 6-1, the primary air channel 1 is set in the annular inner secondary air channel 4, the inner secondary air channel 4 is set in the annular outer secondary air channel 6, and the inner secondary air channel 4 is An inner secondary air swirler 4-1 is installed, and an outer secondary air swirler 6-1 is installed in the outer secondary air passage 6, which is characterized in that the pulverized coal burner also includes a set of conical annular The separation ring 2, the inner flue gas recirculation passage 3 and the outer flue gas recirculation passage 5, the primary air passage 1 is provided with a group of conical separation rings 2, the small diameter end of a group of conical separati...

specific Embodiment approach 2

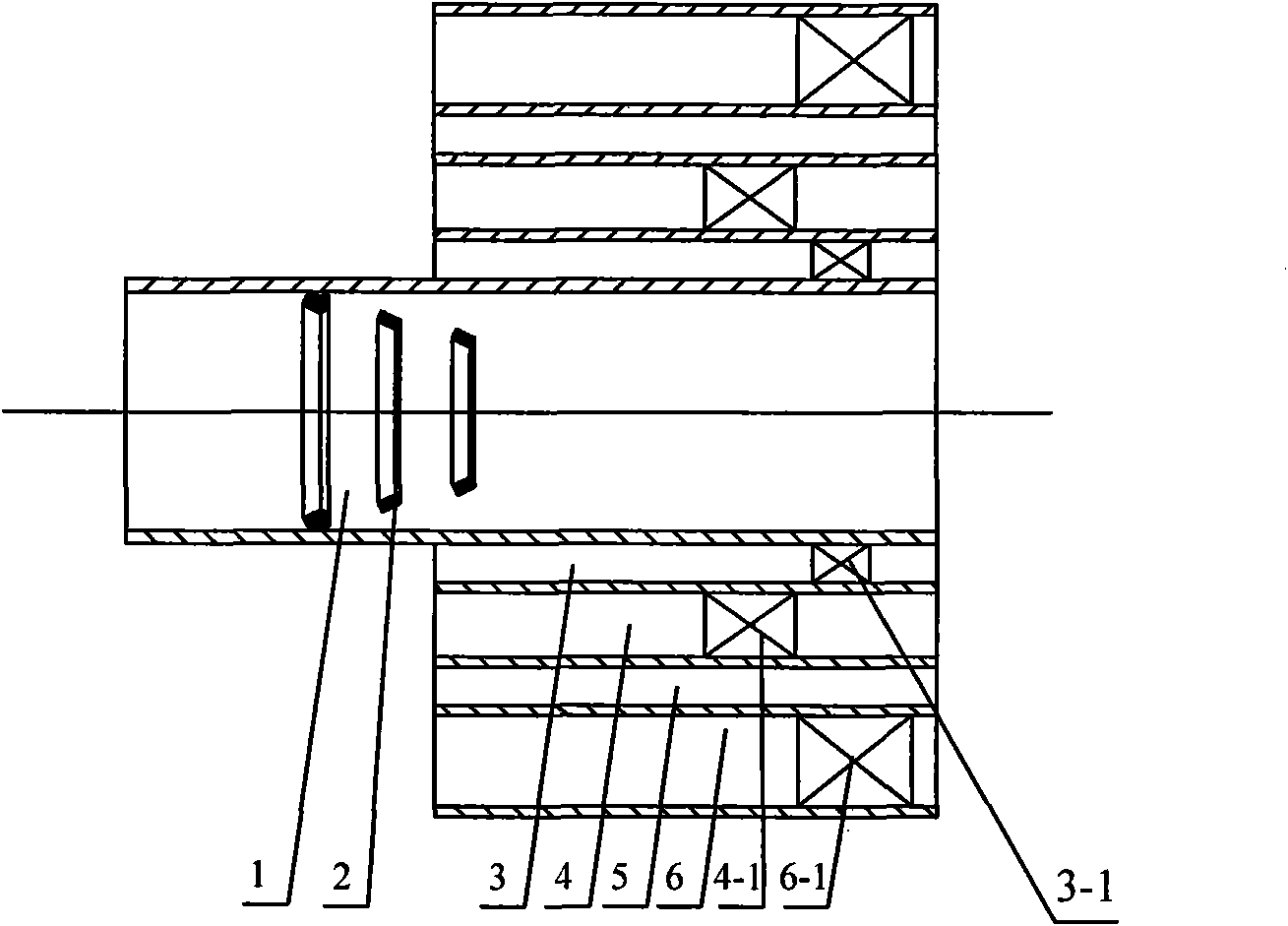

[0009] Specific implementation mode two: combination figure 2 To illustrate this embodiment, the pulverized coal burner of this embodiment also includes an inner flue gas recirculation swirler 3-1, and the inner flue gas recirculation channel 3 is provided with an inner flue gas recirculation swirler 3-1 , this structure is used to control the direction of the flue gas entering the furnace from the inner flue gas recirculation channel 3, so that the airflow rotation can be organized reasonably according to the characteristics of coal quality, the size of the central recirculation zone can be changed, and a suitable central recirculation zone (for pulverized coal combustion) can be formed The size of the required central recirculation zone is determined by the coal quality characteristics). Other components and connections are the same as those in the first embodiment.

[0010] In this embodiment, the inner flue gas recirculation is in the form of swirling flow, and the outer...

specific Embodiment approach 3

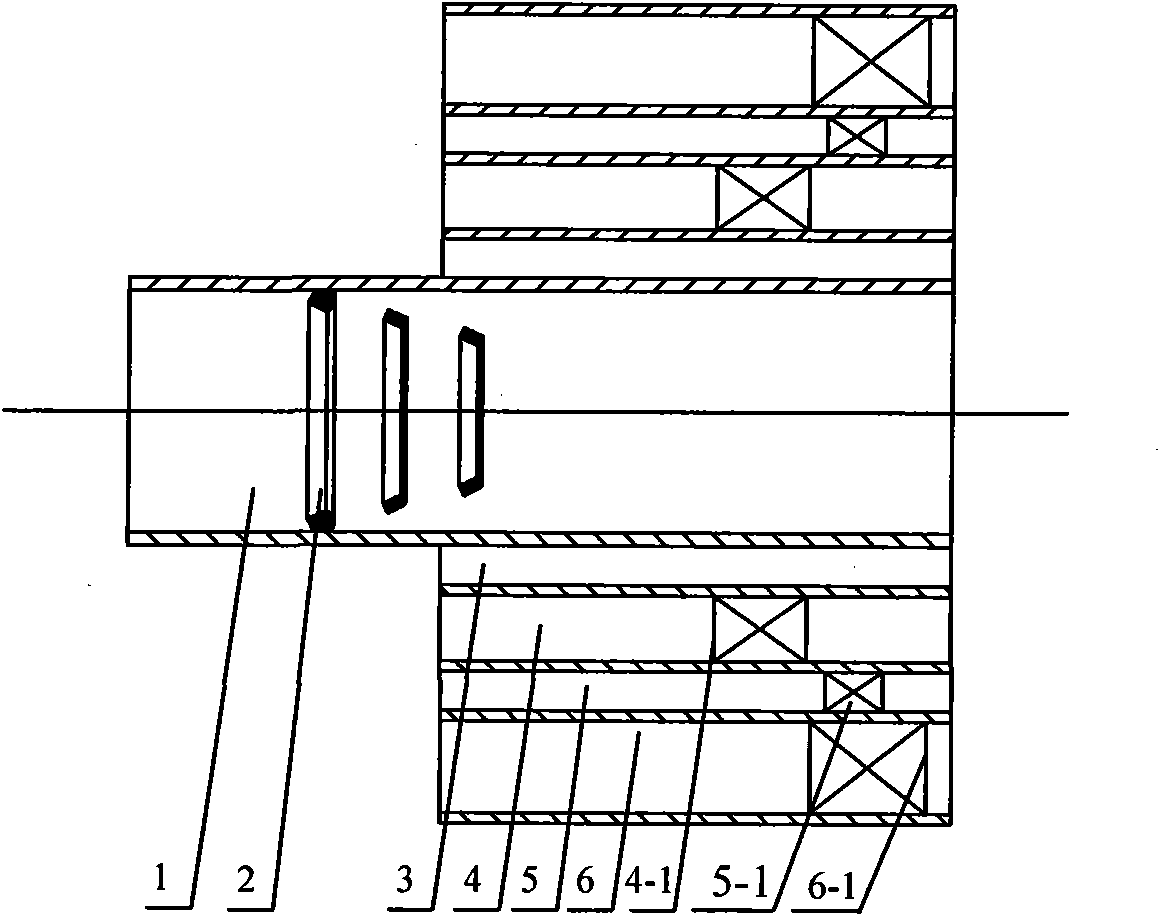

[0011] Specific implementation mode three: combination image 3 To illustrate this embodiment, the pulverized coal burner of this embodiment also includes an outer flue gas recirculation swirler 5-1, and the outer flue gas recirculation channel 5 is provided with an outer flue gas recirculation swirler 5-1. The structure is used to control the direction of the flue gas entering the furnace from the outer flue gas recirculation channel 5, so that the airflow rotation can be organized reasonably according to the coal quality characteristics, the size of the central recirculation zone can be changed, and a suitable central recirculation zone (required for pulverized coal combustion) can be formed. The size of the central recirculation zone is determined by the coal quality characteristics). Other compositions and connections are the same as those in Embodiment 1 or 2.

[0012] In this embodiment, the outer flue gas recirculation is in the form of swirling flow, and the inner flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com