Adjustable stator bar molding press device and machining method thereof

A technology of stator bar and processing method, which is applied in the directions of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problem of increasing the labor intensity of operators and the production cost of motors, affecting the service life of hydro-generators, affecting the production cycle of products, etc. problems, to achieve the effect of ensuring product quality, good product quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

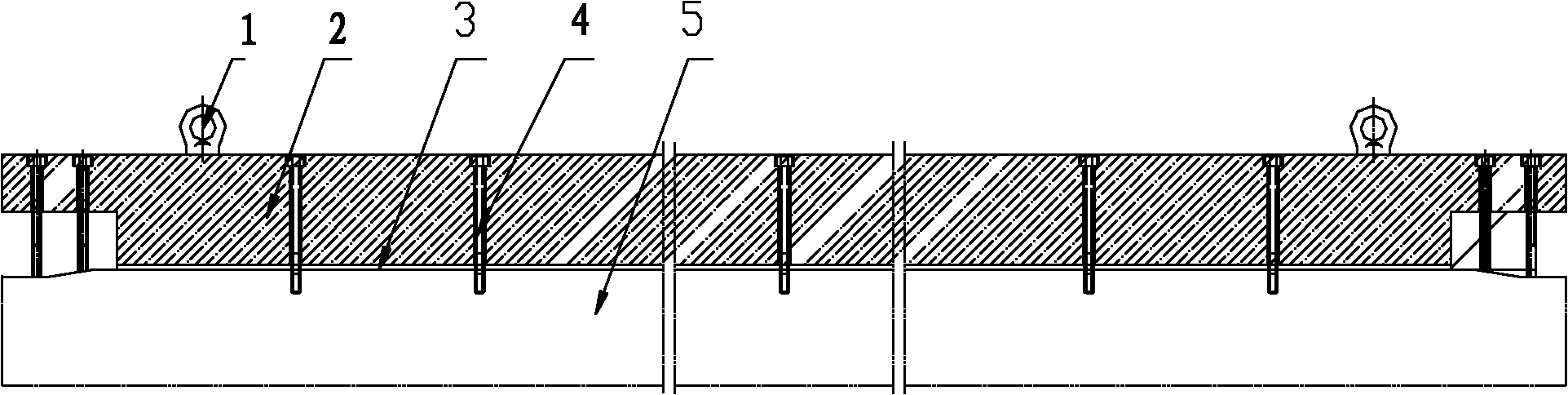

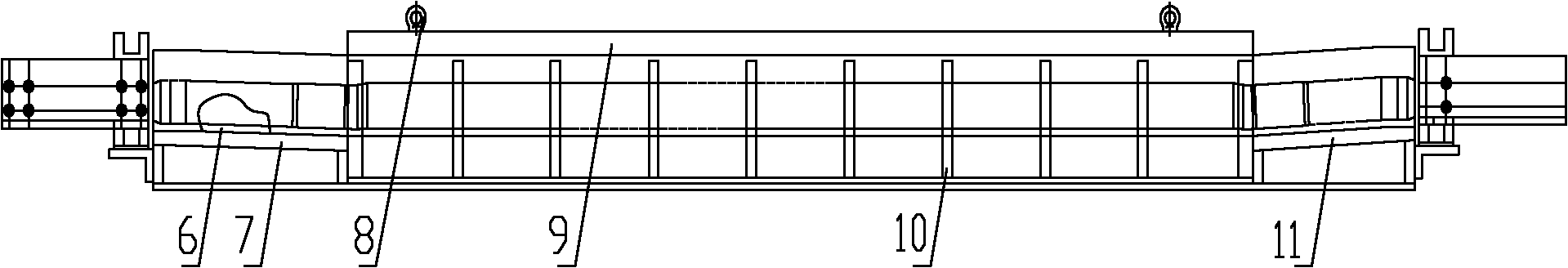

[0016] Embodiment 1 An adjustable stator bar profiling device, including a linear weight 2, a straight upper weight 5, a countersunk screw 4, and an adjustable gasket 3. The linear weight has a notch at the center, The notch is 1.5-2.5mm, and the holes are set at equal distances. Insert the linear upper weight into the notch, and clamp the handle with countersunk screws. There is an adjustable gasket between the linear weight and the linear upper weight. The linear weight is provided with a suspension ring 1, and the thickness of the adjustable spacer 3 is 1mm.

Embodiment 2

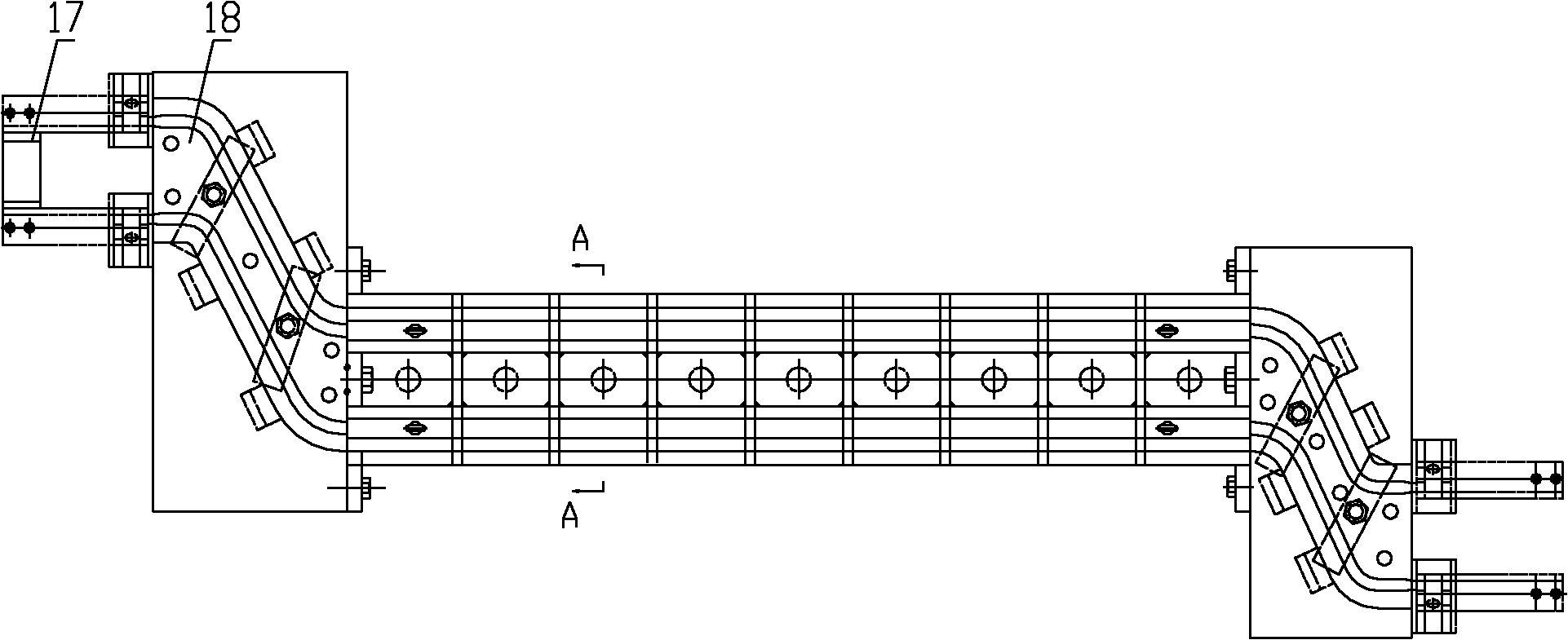

[0017] Embodiment 2 An adjustable stator wire rod profiling processing method, the processing steps are: put the shaped upper and lower stator wire rods on the brackets respectively, remove the cloth tape, and stick it on both sides of the stator wire rod Multi-adhesive mica board, mid-temperature curing multi-adhesive mica board is used between the rows of stator wire rods, and the outsourcing polytetrafluoroethylene tape is used for demoulding; adjust the glue mold between the upper and lower stator wire rod strands on the multi-head hydraulic machine. Horizontal cylinder, The position of the vertical cylinder; according to the inter-strand pressing process, when the wire rod is out of the mold, remove the PTFE tape and polyester film, put it in the cooling and shaping mold for shaping; after cooling, clean the chamfer and adjust the pad slice to adjust the size.

[0018] The specific manufacturing process of this embodiment: 1. First, put the upper and lower stator wire rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com