Reactor and method for preparing isocyanate

An isocyanate and reactor technology, which is applied to the reactor and field for preparing isocyanate, can solve the problems of long length, increased investment in device construction, difficulty, etc., and achieves the effects of reducing overall length, reducing investment and increasing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

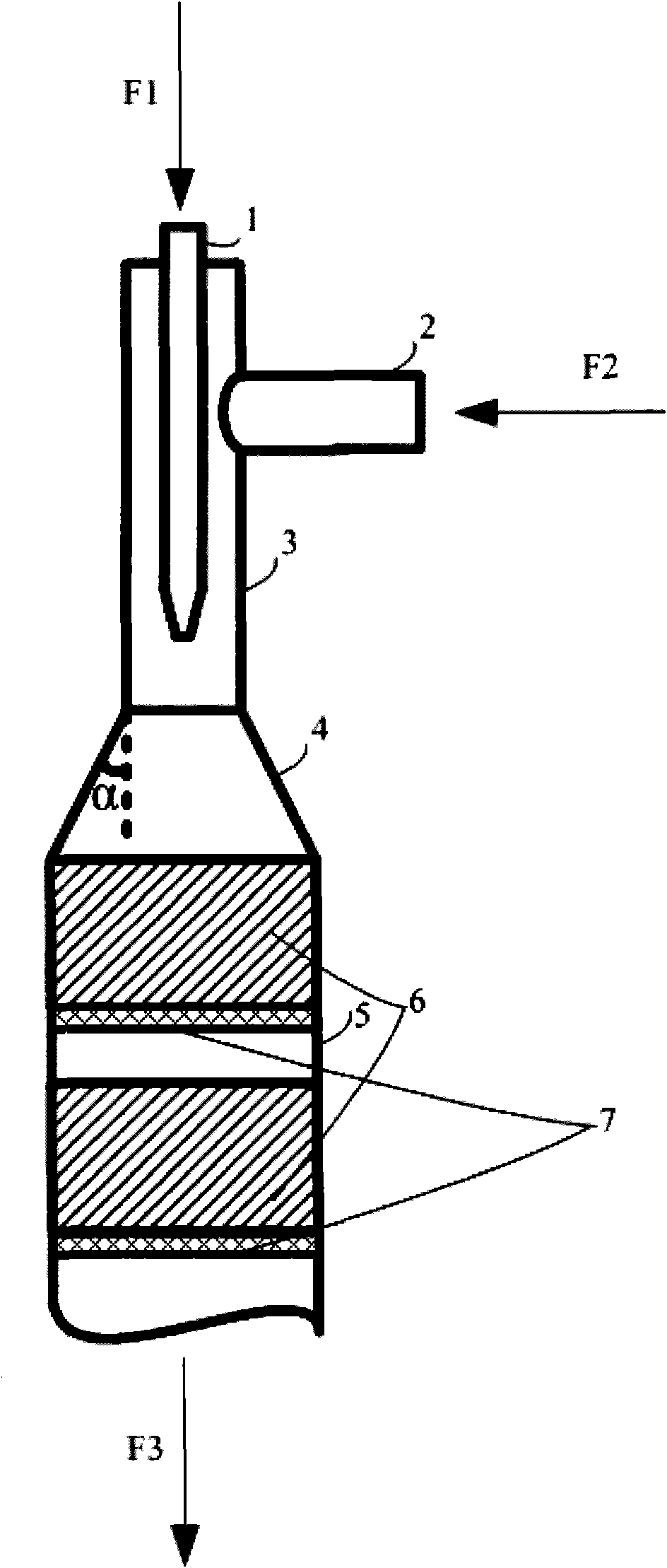

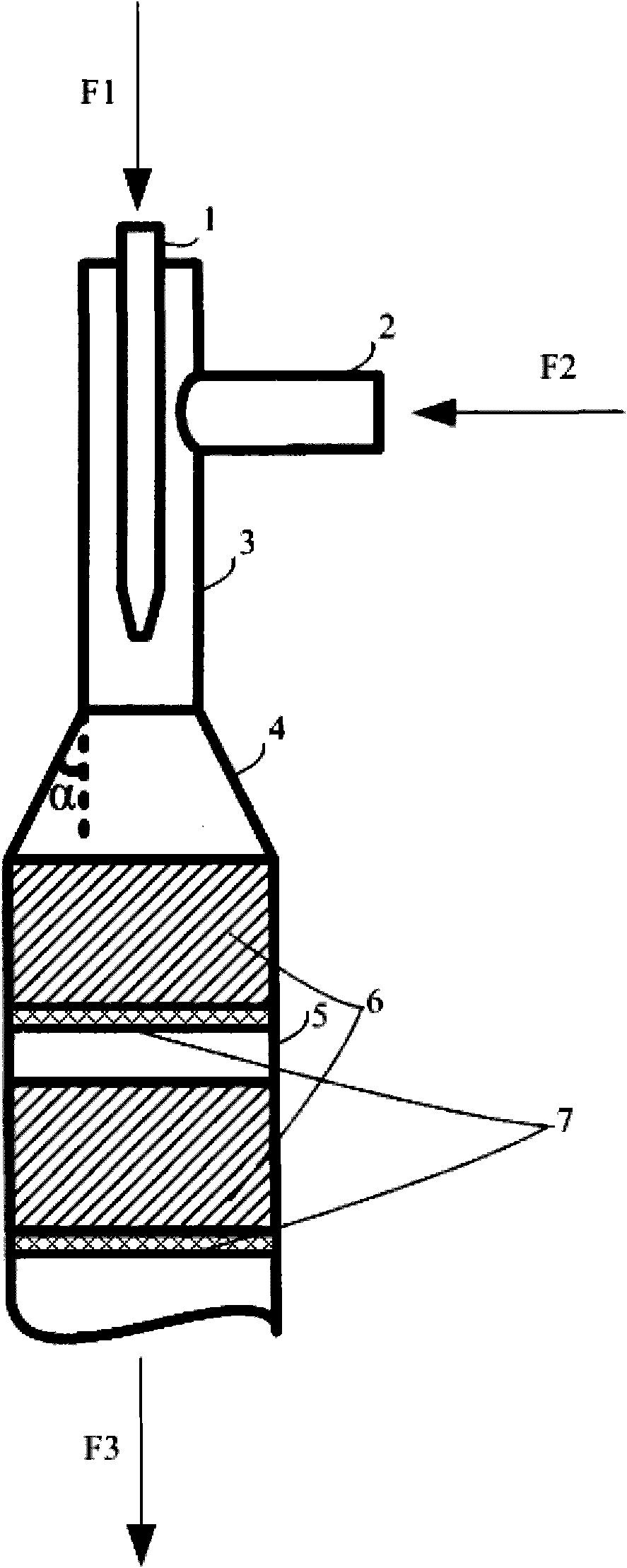

[0034] Using the same central jet mixer, variable diameter connection element and single circular tube reactor as in Comparative Example 2, the structured packing of silicon carbide was added in the tube reactor to increase the mass transfer and heat transfer in the reaction process Effect. The silicon carbide structured packing is customized by the Shenyang Metal Research Institute of the Chinese Academy of Sciences. It is placed from the lower end of the variable diameter connection element. Two sections of silicon carbide structured packing are arranged in the tubular reactor, and each section is fixed by a grid support plate. Each section of the packing The length is 2m, and the distance between two sections of filler is 0.6m.

[0035] At 320°C, the mixed gas of 2,4-toluenediamine and 2,6-toluenediamine with a mass ratio of 80:20 was mixed and diluted with o-dichlorobenzene, and o-dichlorobenzene (ODCB) and diamine The molar ratio is 3:1. The diluted diamine mixed gas an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com