Square pile high strength concrete

A high-strength concrete and concrete technology, which is applied in the field of high-strength concrete for square piles, can solve the problems of not being able to adapt to economical production, not being able to meet high-strength requirements, and low strength, so as to be beneficial to alkaline protection, increase alkalinity, and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

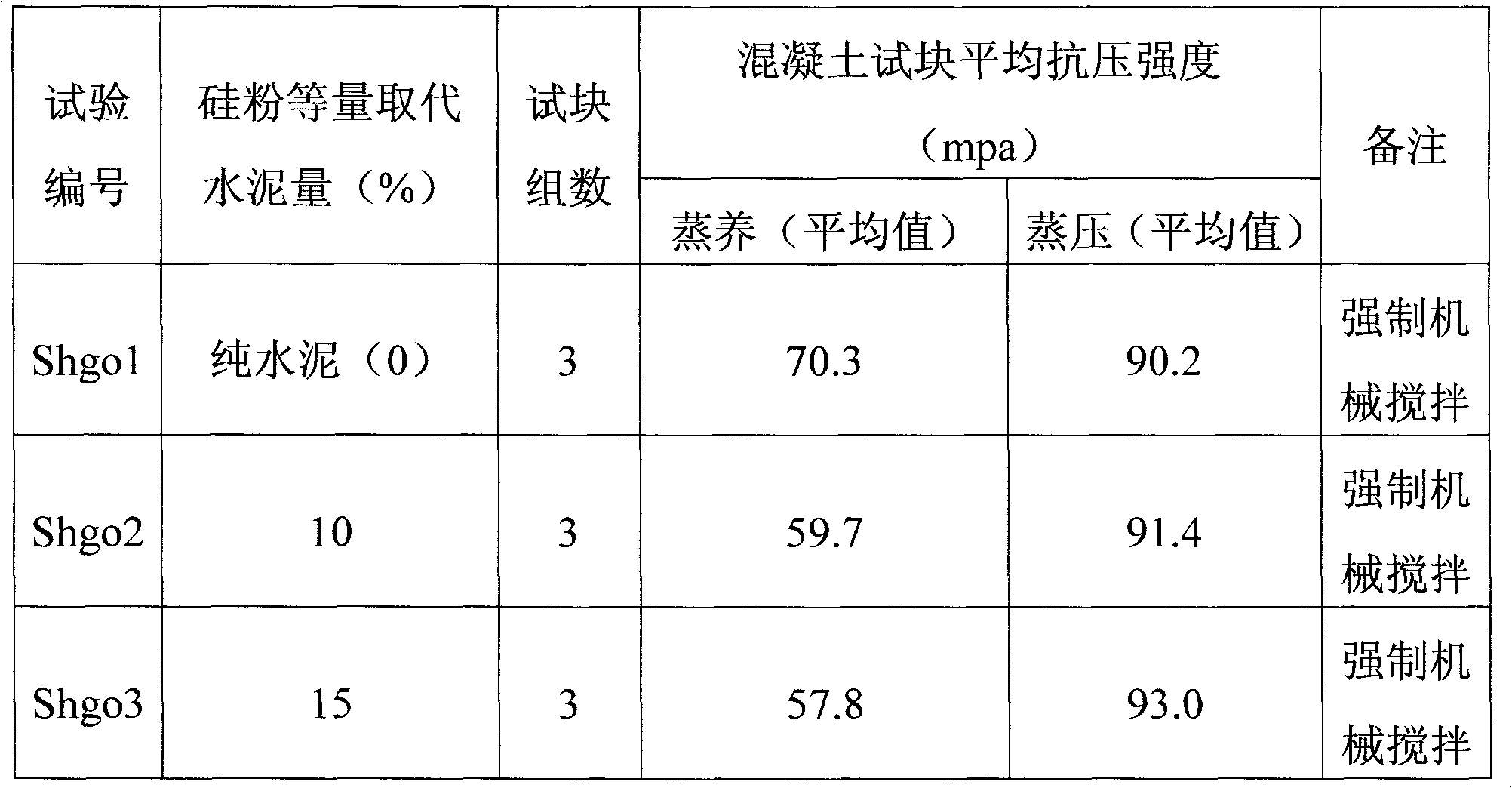

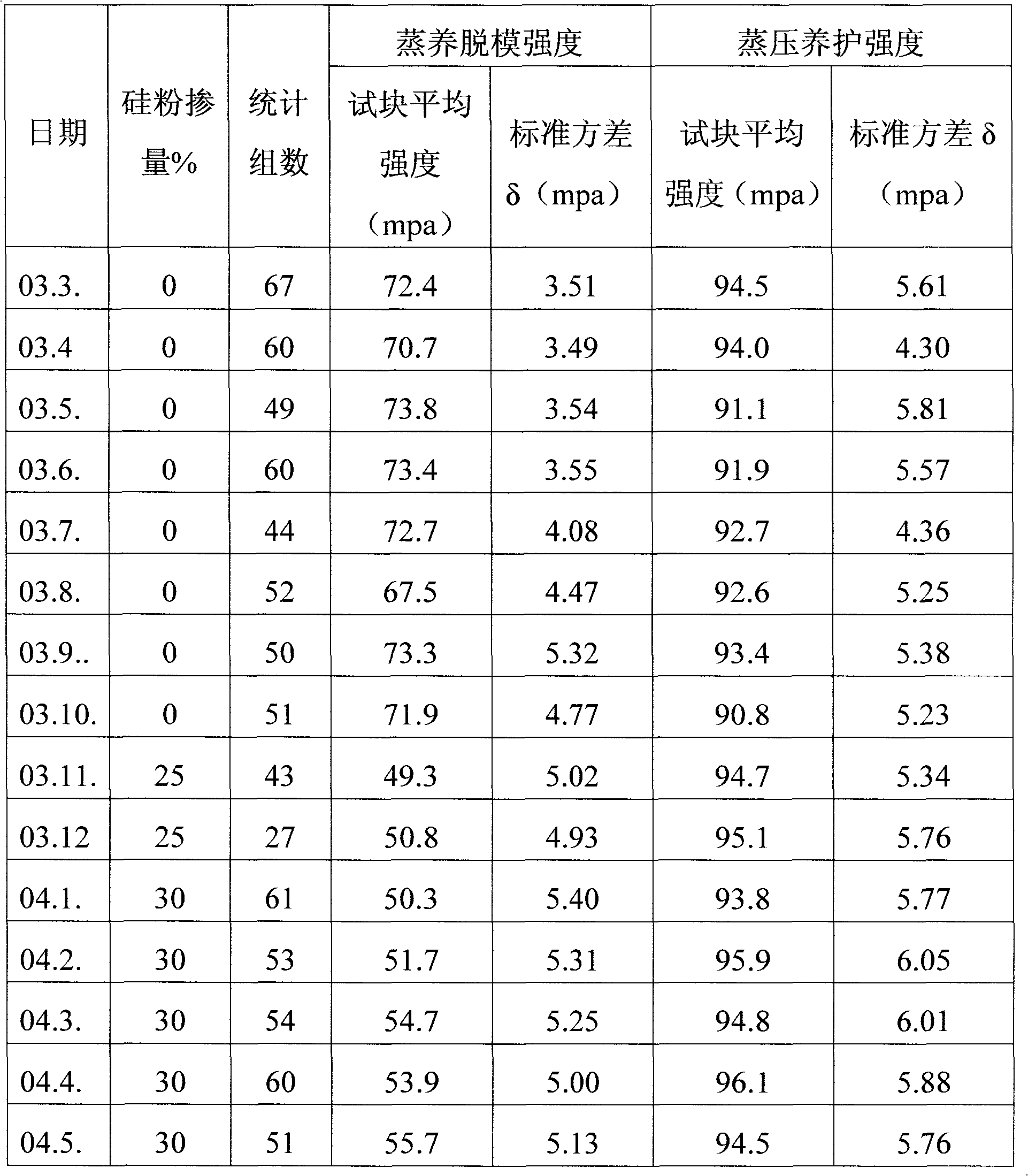

Examples

Embodiment Construction

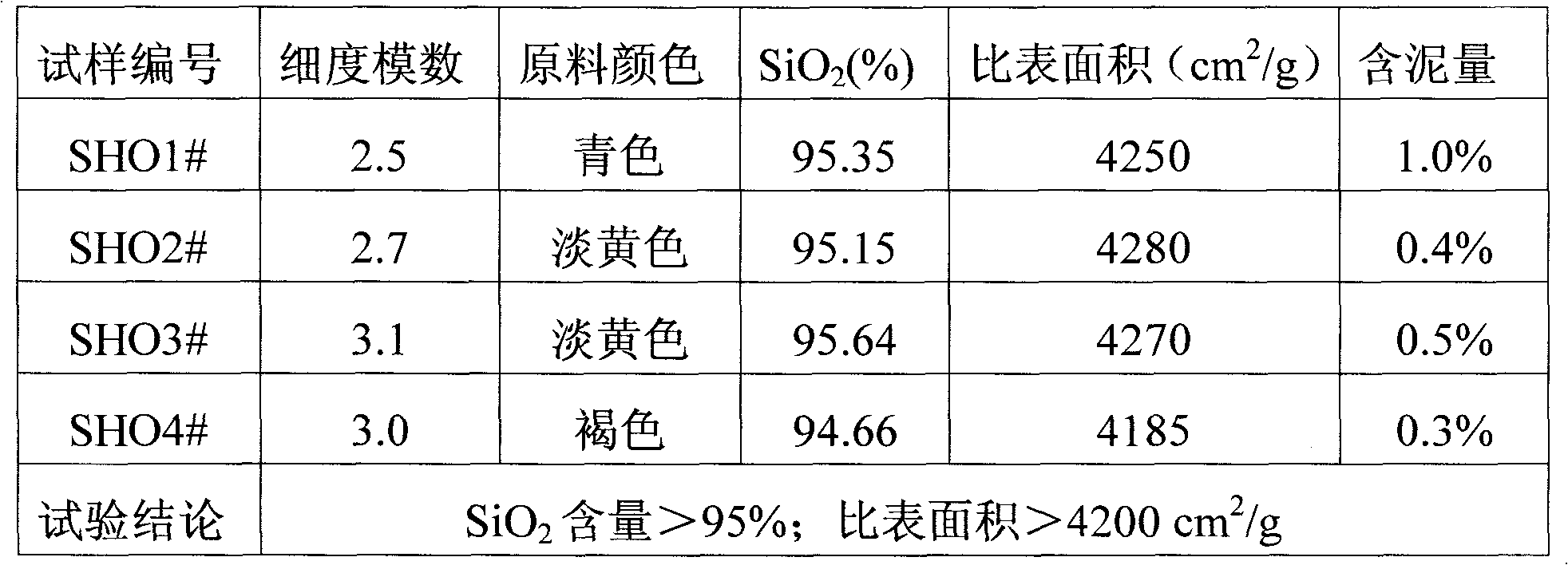

[0009] 1. Material performance test and requirements for making silicon powder

[0010] 1. Quality requirements for raw sand used as silica fume

[0011] A. The mud content of the raw sand must be ≤0.5%, and the mud content ≤0.1%, otherwise it needs to be cleaned and screened;

[0012] B. The fineness modulus of raw sand should be between 2.6 and 3.2, and its moisture content should be ≤5.0%, and the moisture content after drying treatment must be <1.0%;

[0013] C. The content of harmful substances such as mica and SO3 in the raw sand should meet the requirements of GB / T14682-2001;

[0014] 2. The quality requirements of the ground silicon powder after being ground by a ball mill

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com