Chlorine ion curing agent for sea sand and preparation method and applications thereof

A technology of chloride ion and curing agent, which is applied in the direction of chemical instruments and methods, inorganic chemistry, iron compounds, etc., can solve problems such as adverse effects on mechanical properties, and achieve the goals of avoiding the deterioration of mortar mechanical properties, good working performance, and improving mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

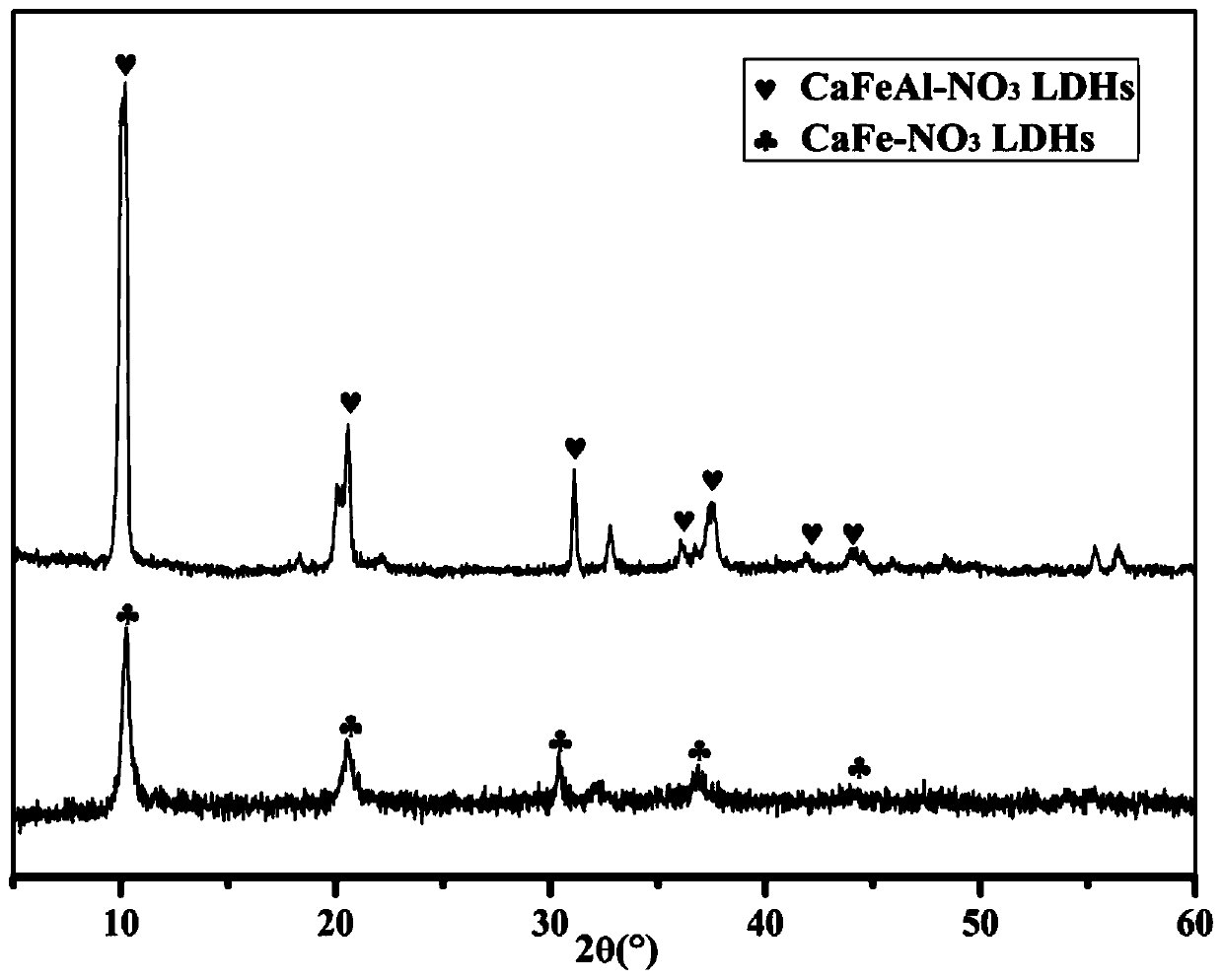

[0041] CaFe-NO in chloride ion curing agent used in sea sand 3 LDHs, CaFeAl-NO 3 The preparation method of LDHs includes the following steps:

[0042] (1)CaFe-NO 3 Synthesis and preparation of LDHs: Dissolve 40mmol calcium nitrate tetrahydrate and 15mmol ferric nitrate nonahydrate in 100mL distilled water to prepare A solution; add A solution dropwise to 100mL 1mol / L sodium hydroxide solution (nitrogen protection ), after the titration is completed, magnetically stirred for 36 hours, then filtered to neutrality, dried in a vacuum drying oven at 80°C for 12 hours, and the obtained product is ground into powder to obtain.

[0043] (2)CaFeAl-NO 3 Synthesis and preparation of LDHs: Dissolve 100mmol calcium nitrate tetrahydrate, 10mmol ferric nitrate nonahydrate, 40mmol aluminum nitrate nonahydrate in 100mL distilled water to prepare B solution; dissolve 260mmol sodium hydroxide and 120mmol sodium nitrate in 100mL Prepare solution C; add solution B and solution C dropwise to a three...

Embodiment 2

[0045] CaFe-NO in chloride ion curing agent used in sea sand 3 LDHs, CaFeAl-NO 3 The preparation method of LDHs includes the following steps:

[0046] 1. CaFeL-NO 3 Synthesis and preparation of DHs: Dissolve 10mmol of calcium nitrate and 5mmol of ferric nitrate in 100mL of distilled water to prepare A solution; add A solution dropwise to 30mL of 1mol / L sodium hydroxide solution (gas flow rate is 100ml / min Nitrogen protection), after the titration is completed, magnetically stirred for 12 hours, then filtered to neutrality, dried in a vacuum drying oven at 60°C for 24 hours, and the obtained product is ground into powder to obtain.

[0047] 2. CaFeAl-NO 3 Synthesis and preparation of LDHs: Dissolve 30mmol of calcium nitrate, 5mmol of ferric nitrate, and 10mmol of aluminum nitrate in 120mL of distilled water to form B solution; dissolve 80mmol of sodium hydroxide and 100mmol of sodium nitrate in 120mL of distilled water to form Solution C: Add solution B and solution C dropwise t...

Embodiment 3

[0049] CaFe-NO in chloride ion curing agent used in sea sand 3 LDHs, CaFeAl-NO 3 The preparation method of LDHs includes the following steps:

[0050] 1. CaFeL-NO 3 Synthesis and preparation of DHs: Dissolve 50mmol of calcium nitrate and 25mmol of ferric nitrate in 120mL of distilled water to prepare A solution; add A solution dropwise to 140mL of 1mol / L sodium hydroxide solution (gas flow rate is 100ml / min Nitrogen protection), after the titration is completed, magnetically stirred for 48 hours, then filtered to neutrality, dried in a vacuum drying oven at 120°C for 6 hours, and the obtained product is ground into powder to obtain.

[0051] 2. CaFeAl-NO 3 Synthesis and preparation of LDHs: Dissolve 150mmol of calcium nitrate, 20mmol of ferric nitrate, and 50mmol of aluminum nitrate in 150mL of distilled water to prepare B solution; dissolve 300mmol of sodium hydroxide and 200mmol of sodium nitrate in 150mL of distilled water to prepare Solution C: Add solution B and solution C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com