Method and device for preparing ammonia through active molecule oxidation flue gas double-circulation denitration

An active molecule and double-cycle technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of low income, high denitrification operation cost, difficult treatment of active molecule oxidation and denitrification wastewater, and reduce wastewater discharge. Quantity, large environmental and economic benefits, and the effect of increasing alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

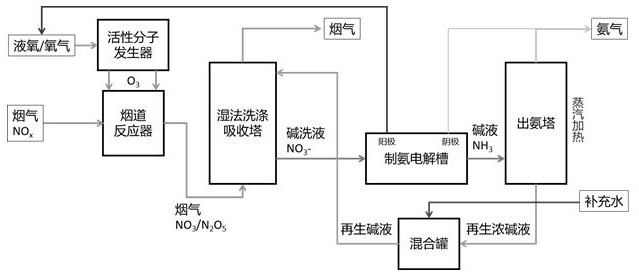

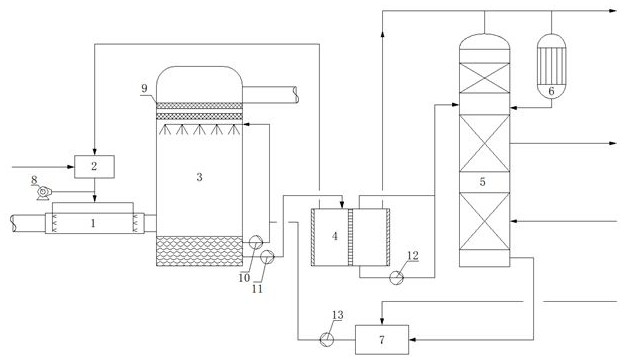

[0057] like figure 1 and 2 As shown in the figure, the flue gas with a temperature of 60-160 °C after the previous treatment enters the flue reactor 1, and the active molecules O produced by the active molecule generator 2 3 Mixed to convert nitrogen oxides in flue gas into high-valence nitrogen oxides through oxidation reaction. After oxidation, the flue gas enters the wet scrubbing absorption tower 3, and the lye is sprayed uniformly through the top of the tower to absorb the high-valence nitrogen oxides in the flue gas into a nitrate-containing solution, and the flue gas enters the mist eliminator 9 after removing droplets. The rear flue gas treatment device. The absorbed nitrate-containing solution enters the ammonia-producing electrolytic cell 4, and is converted into ammonia molecules through catalytic electrolysis of nitrate ions, and the ammonia-containing solution enters the ammonia outlet tower 5, and the ammonia is evaporated under heating, and the water vapor is ...

Embodiment 2

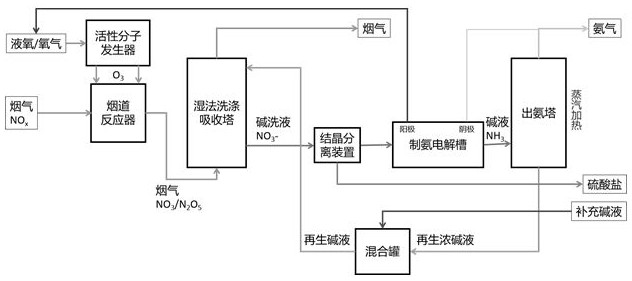

[0060] like image 3 and 4As shown, the flue gas with a temperature of 60~160°C after the previous treatment (SOx vol% / NOx vol% in the flue gas is 2) enters the flue reactor 1, and the active molecule O produced by the active molecule generator 2 3 Mixed to convert nitrogen oxides in flue gas into high-valence nitrogen oxides through oxidation reaction. After oxidation, the flue gas enters the wet scrubbing absorption tower 3, and the slaked lime lye is evenly sprayed through the top of the tower to absorb the high-valent nitrogen oxides in the flue gas into a nitrate-containing solution, and the flue gas is removed by the mist eliminator 9. Enter the rear flue gas treatment device. The absorbed nitrate-containing solution enters the crystallization separation device 14 to separate the calcium sulfate crystals enriched in the solution, and generate gypsum products after subsequent treatment. The solution after desulfurization enters the ammonia production electrolytic cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com