Method for improving tensile strength of carbon fibers

A technology of tensile strength and carbon fiber, applied in the field of carbon fiber preparation, can solve the problems of low tensile strength of carbon fiber, and achieve the effects of improving mechanical properties, tensile strength and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

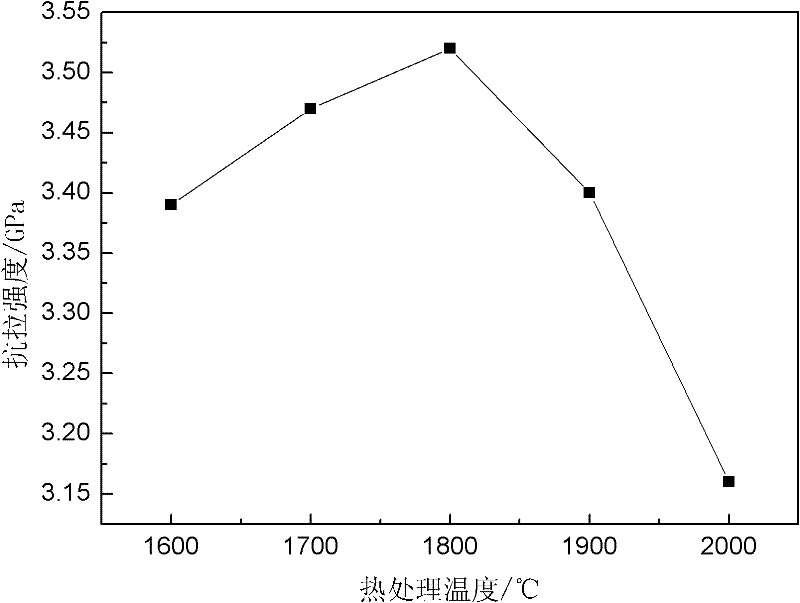

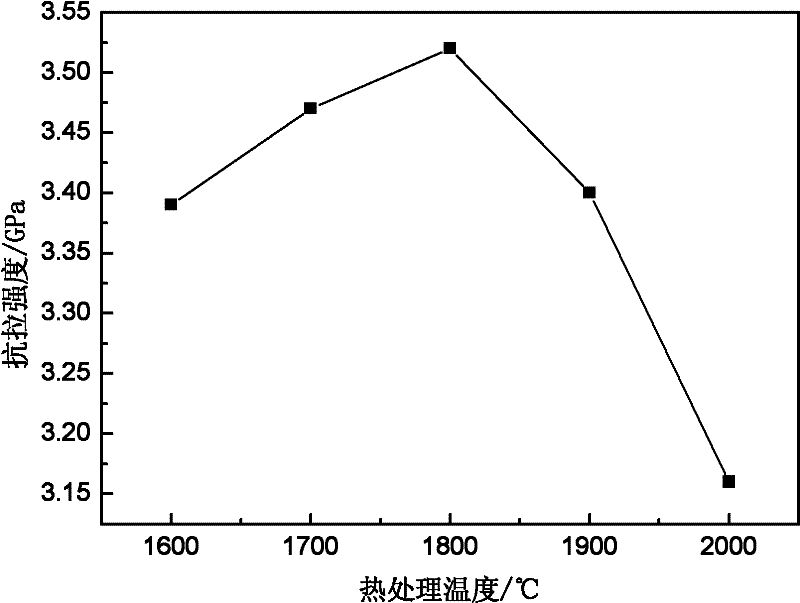

[0026] A brand of T300 carbon fiber that needs heat treatment is taken as the raw material, and its mechanical properties are 3.52GPa in tensile strength and 213GPa in tensile modulus. Through a heat treatment in the range of 1500-2000 °C, a section of carbon fiber was taken every 50 °C to measure its tensile strength, and it was found that the highest value of tensile strength appeared at 1900 °C, which was 3.81GPa; the domestic T300 carbon fiber was treated at 1900 °C The intermediate product was obtained, and then the raw material and the intermediate product were heat-treated under the same experimental conditions at 2400°C. Through mechanical performance tests, it was found that the tensile strength of the carbon fiber after one-step heat treatment and step-by-step heat treatment was 2.62GPa and 2.96GPa, respectively. The modulus is 341GPa and 347GPa, respectively. It can be seen that the tensile strength of carbon fiber with step heat treatment is 13% higher than that of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com