Spinning method of polyacrylonitrile-based carbon fiber precursors

A technology of polyacrylonitrile-based carbon fiber and raw silk, which is applied in the directions of drawing spinning, fiber chemical characteristics, and single-component synthetic polymer rayon, etc. strength and strength, reducing the effect of the skin-core structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

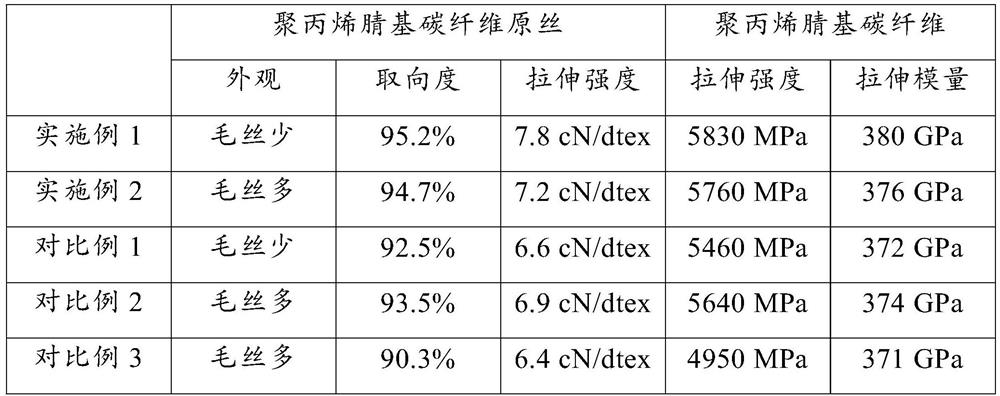

Examples

Embodiment 1

[0033] The formulated mass concentration is 68% dimethyl sulfoxide deionized aqueous solution, and the temperature of the dimethyl sulfoxide deionized aqueous solution is maintained at 40 ± 1 ° C; then add deion ammonia water to the dimethyl sulfoxide deionized aqueous solution. Also a solid solution having a pH of 9.8.

[0034] The polyacrylonitrile spinning liquid is sprayed into the solidification liquid after spinning, and the initial fiber is obtained; after washing the obtained initial fiber, the dry temperature is maintained between 170 and 80 ° C and filled with nitrogen. In the machine, the thermal roller drafting is dried (drying the crystal densification time of 150s, the starting time of the thermal roller stretching is starting after the drying and densification, the heat roller is 1.3 times), then then The steam drafting (three times the steam drafting is 3 times) is heat-fixed, and the polyacrylonitrile carbon fiber is produced.

Embodiment 2

[0036] The formulated mass concentration is 68% dimethyl sulfoxide deionized aqueous solution, and the temperature of the dimethyl sulfoxide deionized aqueous solution is maintained at 40 ± 1 ° C; then add deion ammonia water to the dimethyl sulfoxide deionized aqueous solution. Also a solid solution having a pH of 9.8.

[0037] The polyacrylonitrile spinning material is sprayed into the solidification liquid after spinning, and the initial fiber is obtained; after washing the resulting initial fiber, it is placed in a dry temperature between 170 to 80 ° C and the air-filled steam heat roller drying. In the machine, the thermal roller drafting is dried (drying the crystal densification time of 150s, the starting time of the thermal roller stretching is starting after the drying and densification, the heat roller is 1.3 times), then then The steam drafting (three times the steam drafting is 3 times) is heat-fixed, and the polyacrylonitrile carbon fiber is produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com