Method for producing fine denier terylene BCF filaments and spinning plate

A fine-denier polyester and production method technology, which is applied in the direction of spinneret assemblies, filament/thread molding, rayon manufacturing, etc., can solve the problems of dependence on imports, restricting the development of the carpet industry, and high prices, so as to improve the grade and improve Effects on Profitability and Export Earning Capacity

Active Publication Date: 2010-11-10

JIANGSU KAILI CARPET

View PDF7 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, my country's ultra-fine denier polyester BCF carpet fiber manufacturing is still basically blank, all of which need to be imported, and the price is high, which seriously restricts the development of my country's carpet industry.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Login to View More

Abstract

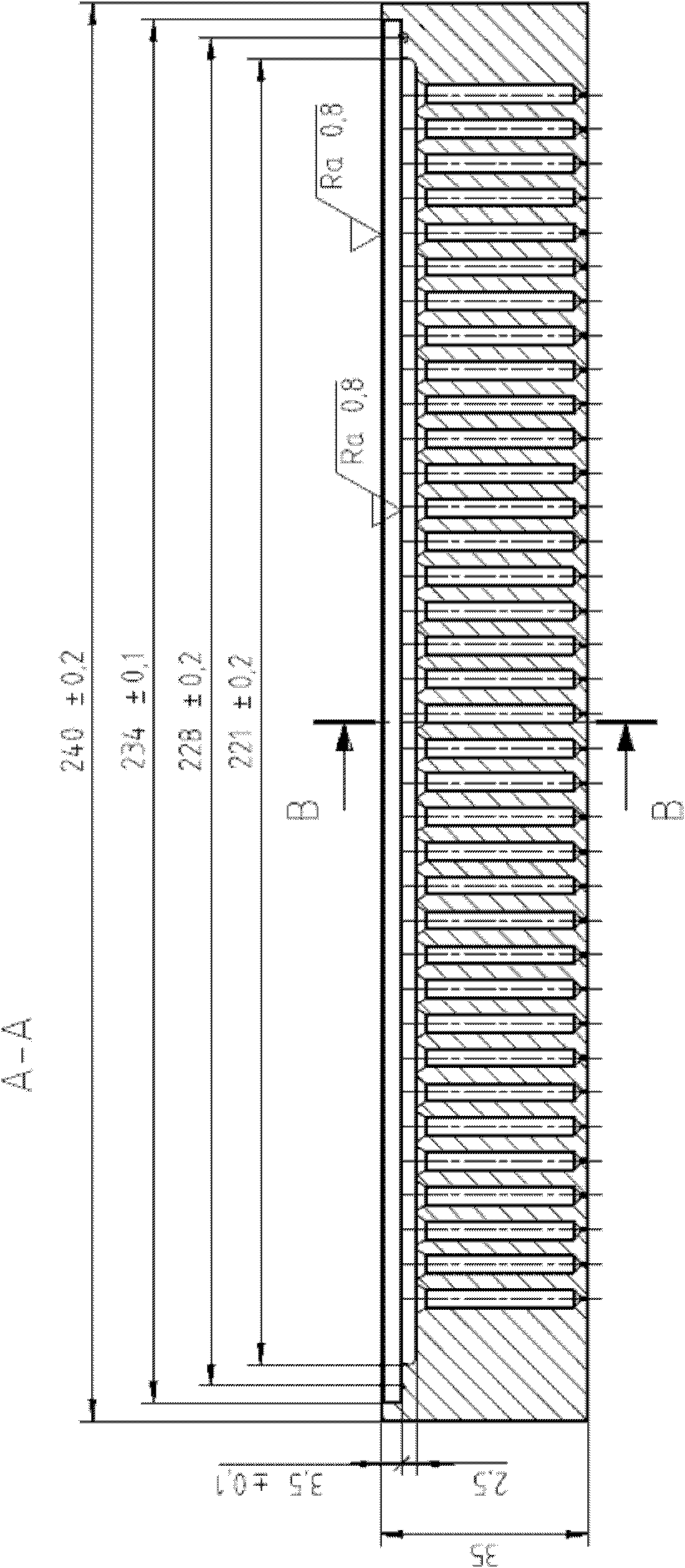

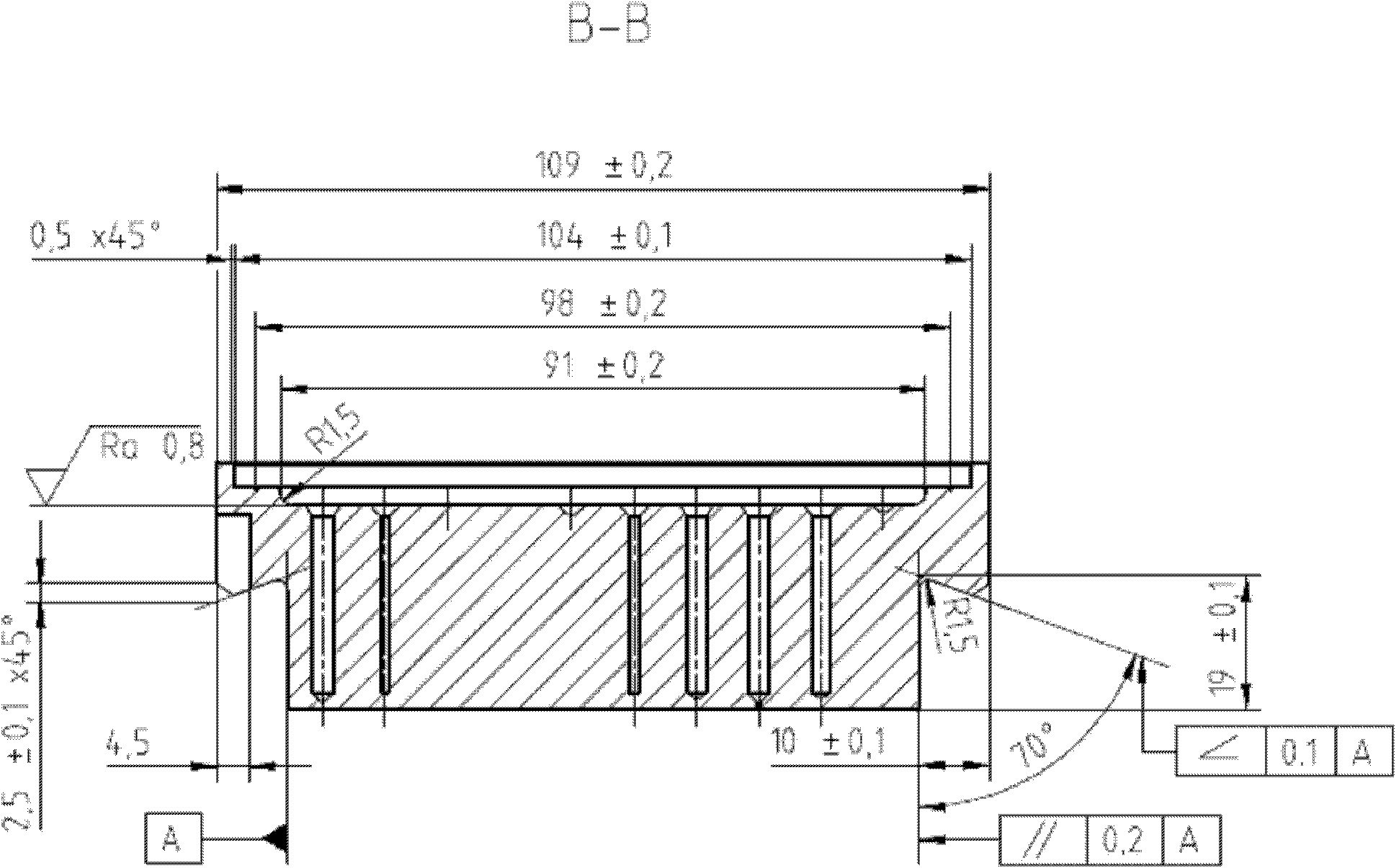

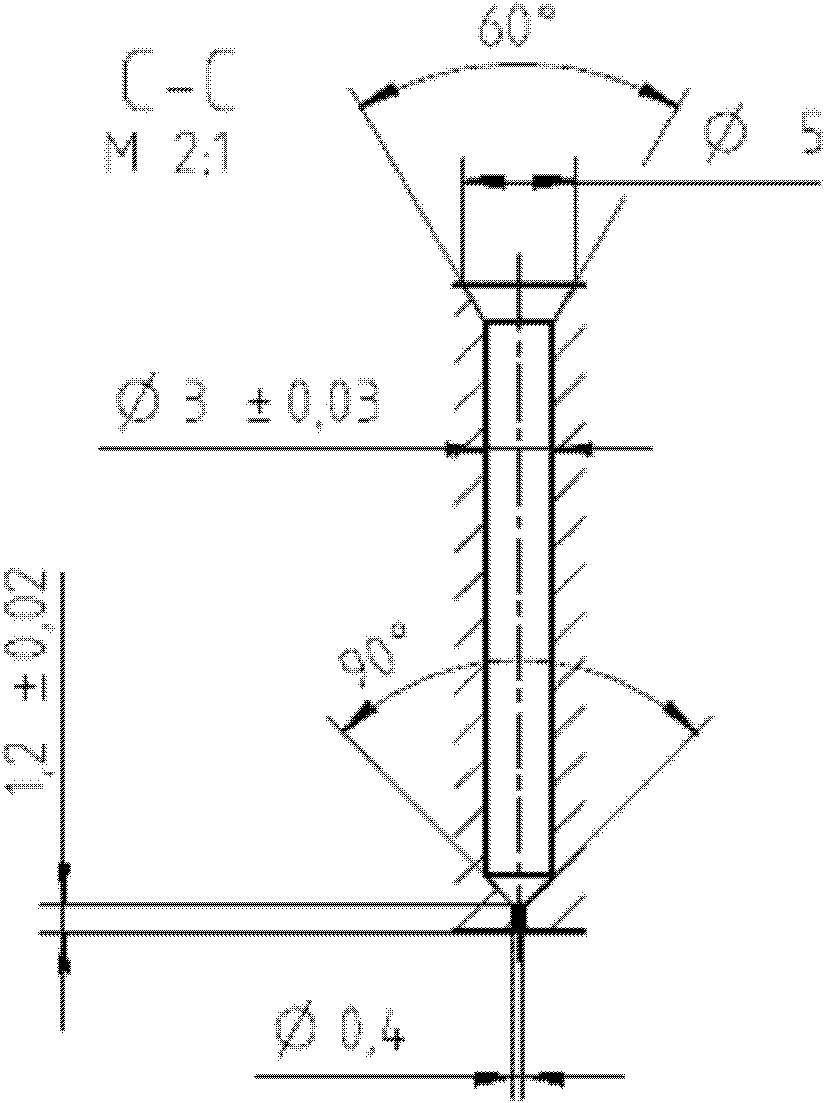

The invention relates to a method for producing fine denier terylene BCF filaments and a spinning plate. The method comprises the following steps of: (1) pre-crystallizing and drying terylene slices, and then melting and extruding the terylene slices through screws, wherein the terylene slices are PET and the viscosity is 0.64 to 1.0; (2) performing spinning through the spinning plate, wherein the hole number of the spinning plate is 330 to 380, the holes are circular holes or three-leaf holes, the aperture of the circular holes is 0.4 to 0.6 millimeters, the ratio of the length to the aperture is 1.5: 1 to 3: 1, the leaf width of the three-leaf holes is 0.1 to 0.1 millimeter, the leaf length is 0.5 to 0.8 millimeter, and the ratio of the length to the aperture is 2: 1 to 3: 1; (3) cooling, namely cooling with side air at the air speed of between 0.1 and 0.15 meter per second and at the temperature of between 18 and 25 DEG C; (4) oiling and drafting; (5) BCF bulking; and (6) cooling shaping, outputting, entanglement network and winding, wherein the fiber number of the fine denier terylene BCF filaments is 1,100 to 2,000 decitexes, and the fiber number of monofilaments is 3.06 to 5.56dpf.

Description

Production method of fine denier polyester BCF filament and spinneret used technical field The invention relates to a production method of fine-denier polyester BCF filament and a spinneret used therefor. Background technique BCF filament, also known as bulked continuous filament yarn, expands and deforms the stretched multifilament yarn, and fixes its bulking and curling effects after setting, so the gap between fibers increases, making the yarn body bulky. BCF filaments are mainly used in carpet weaving. The existing BCF filament production process is a one-step method, and the main steps include spinning, cooling, oiling, stretching, BCF puffing and deformation, cooling and shaping, output, entanglement network, and winding. This one-step production process has high requirements, and it is difficult to obtain filaments with a single filament fineness below 6dpf. Fine denier polyester BCF filament has good bulkiness, soft and comfortable hand feeling. It has the char...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D02G1/00D01D5/088D01D4/02D01D5/253D01F1/02

Inventor 房军

Owner JIANGSU KAILI CARPET

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com