All-solid state dissolved oxygen sensor and preparation method thereof

A dissolved oxygen sensor and all-solid-state technology, which is applied to instruments, screen printing methods, and photoplate-making processes on patterned surfaces. Ease of operation and simplification of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation of a kind of all-solid-state dissolved oxygen sensor comprises the following steps:

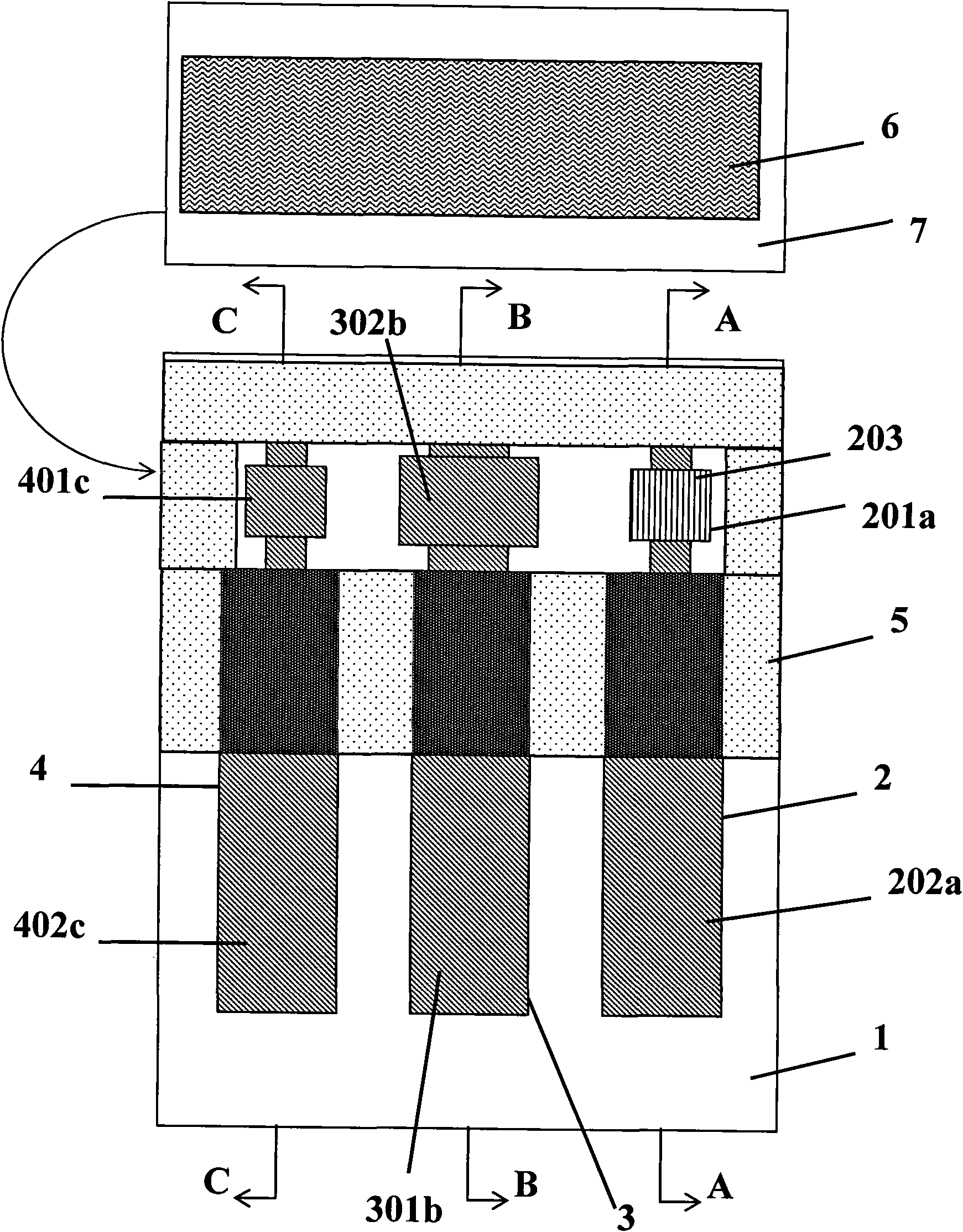

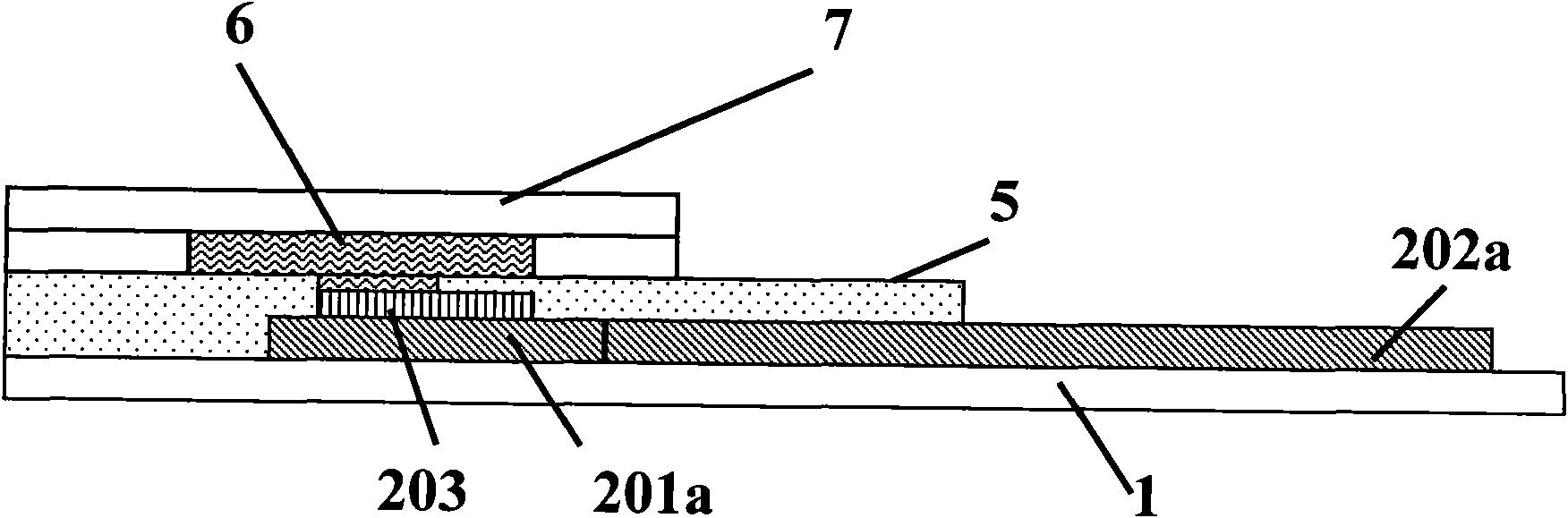

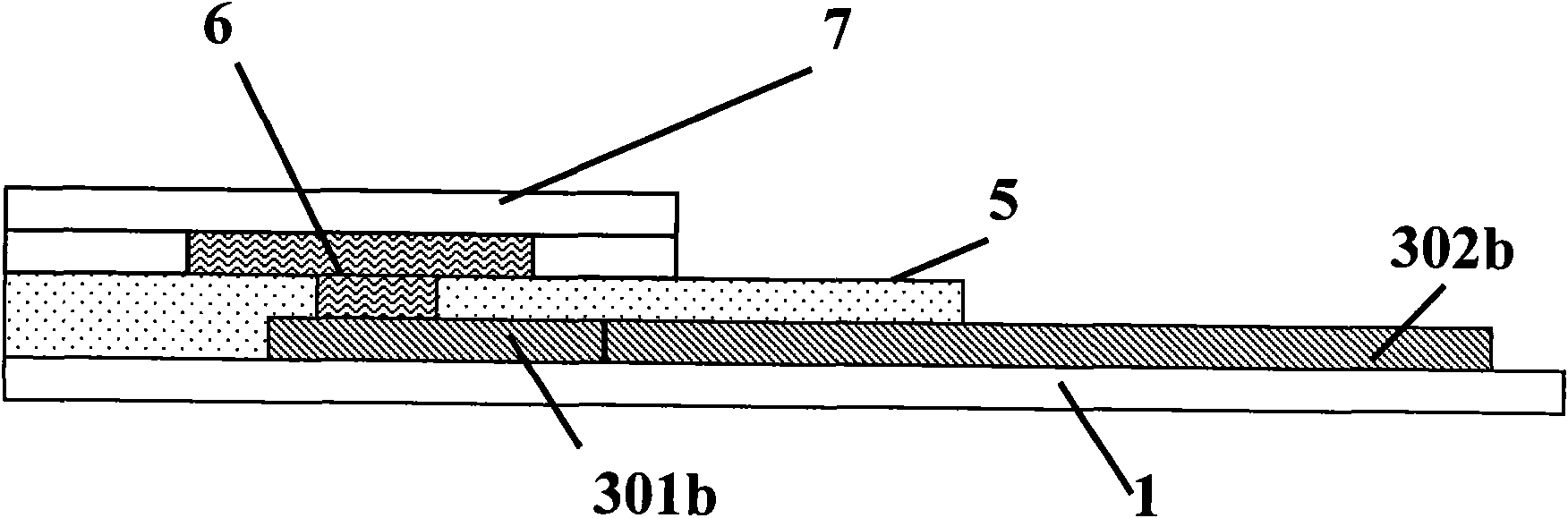

[0054] (1) On the polypropylene substrate covered with a layer of gold foil, laser marking method is used to etch such as figure 1 The reference electrode, the working electrode and the counter electrode of the shape shown, wherein the reaction electrodes of the reference electrode, the working electrode and the counter electrode are all rectangles with a length of 18mm and a width of 4mm;

[0055] (2) Print a layer of silver paste on the reaction electrode of the reference electrode by screen printing, the mesh cloth used is 420 mesh, the mesh distance is 1.5mm, the scraper hardness is 80°, the scraper angle is 64.3°, the scraper Speed 8mm / s, scraper pressure 4kg / cm 2 After printing, dry the substrate in the oven in the dark for 2 minutes, and the oven temperature is 50°C to form a silver film;

[0056] (3) printing insulating material on the substrate, the insulat...

Embodiment 2

[0062] The preparation of a kind of all-solid-state dissolved oxygen sensor comprises the following steps:

[0063] (1) On the polypropylene substrate covered with a layer of gold foil, laser marking method is used to etch such as figure 1 The reference electrode, the working electrode and the counter electrode of the shape shown, wherein the reaction electrodes of the reference electrode, the working electrode and the counter electrode are all rectangles with a length of 18mm and a width of 4mm;

[0064] (2) Print a layer of silver paste on the reaction electrode of the reference electrode by screen printing, the mesh cloth used is 420 mesh, the mesh distance is 1.5mm, the scraper hardness is 80°, the scraper angle is 64.3°, the scraper Speed 8mm / s, scraper pressure 4kg / cm 2 , dry in an oven for 2 minutes in the dark, and the oven temperature is 50°C to form a silver film;

[0065] (3) printing insulating material on the substrate, the insulating material covers the perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com