Organic semiconductor device

A technology of organic semiconductors and organic semiconductor layers, applied in semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., can solve problems such as the inability to control the orientation of organic semiconductor materials, the difficulty in improving the characteristics of organic transistors, and the difficulty in achieving high-performance transistors, etc. , to achieve good orientation control, easy surface modification, and high hole injection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

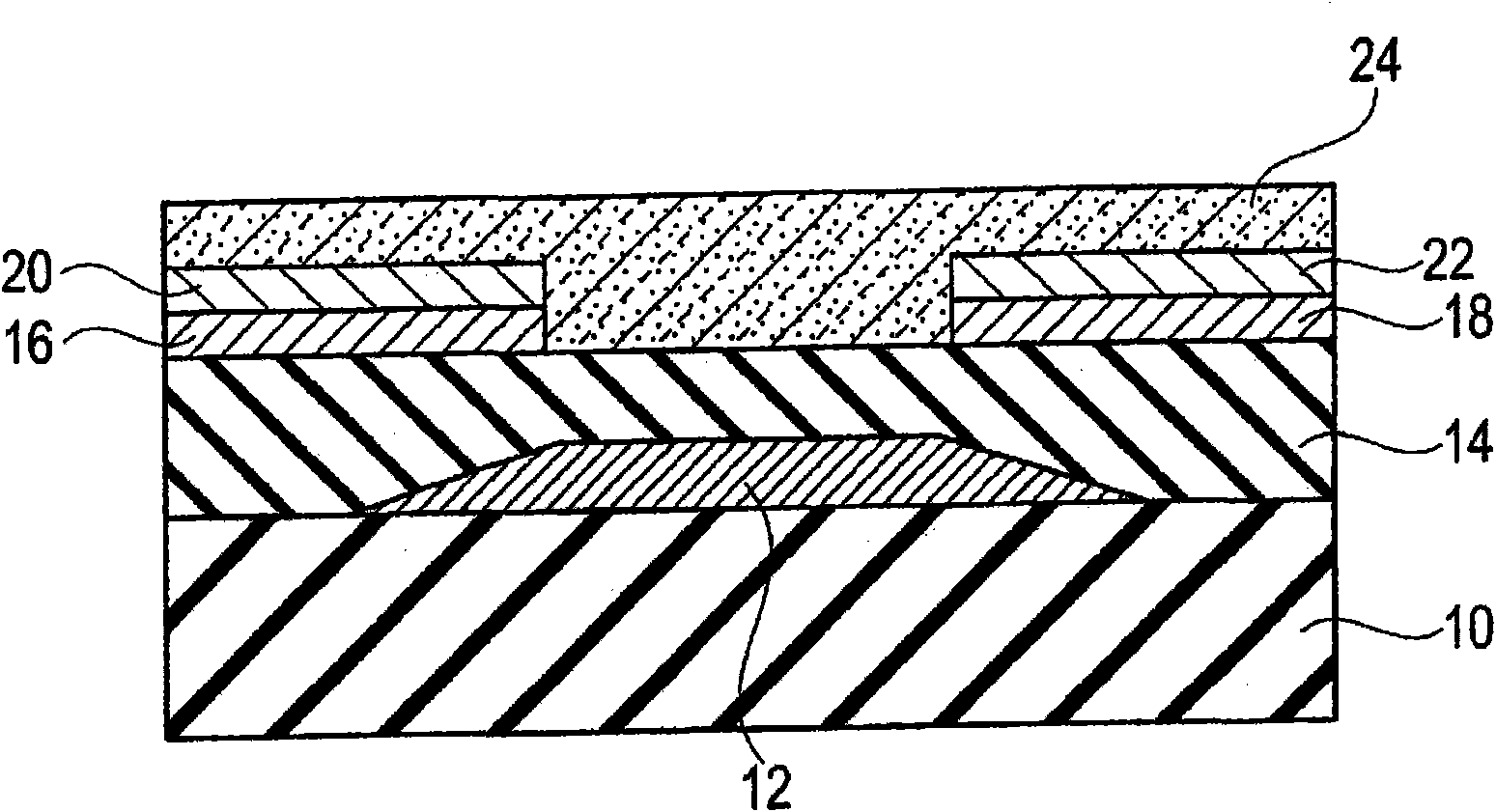

[0105] Figure 5 A schematic cross-sectional structure of the organic semiconductor device according to the first embodiment of the present invention is shown. also, Image 6 and Figure 7 The drain current I of the organic semiconductor device according to the first embodiment of the present invention is shown respectively. D - Drain voltage V D Characteristic example, drain current I D - Gate voltage V G Feature example.

[0106] like Figure 5 As shown, the structure of the organic semiconductor device according to the first embodiment of the present invention has an organic thin film transistor, and the organic thin film transistor has: a substrate 10; a gate 12 arranged on the substrate 10; a gate insulating layer arranged on the gate 12 film 15; the gate insulating film 17 arranged on the gate insulating film 15; the source electrode (16, 20) and the drain (18, 22); and, the organic semiconductor layer 24 provided between the source (16, 20) and the drain (18, 22...

no. 2 Embodiment approach

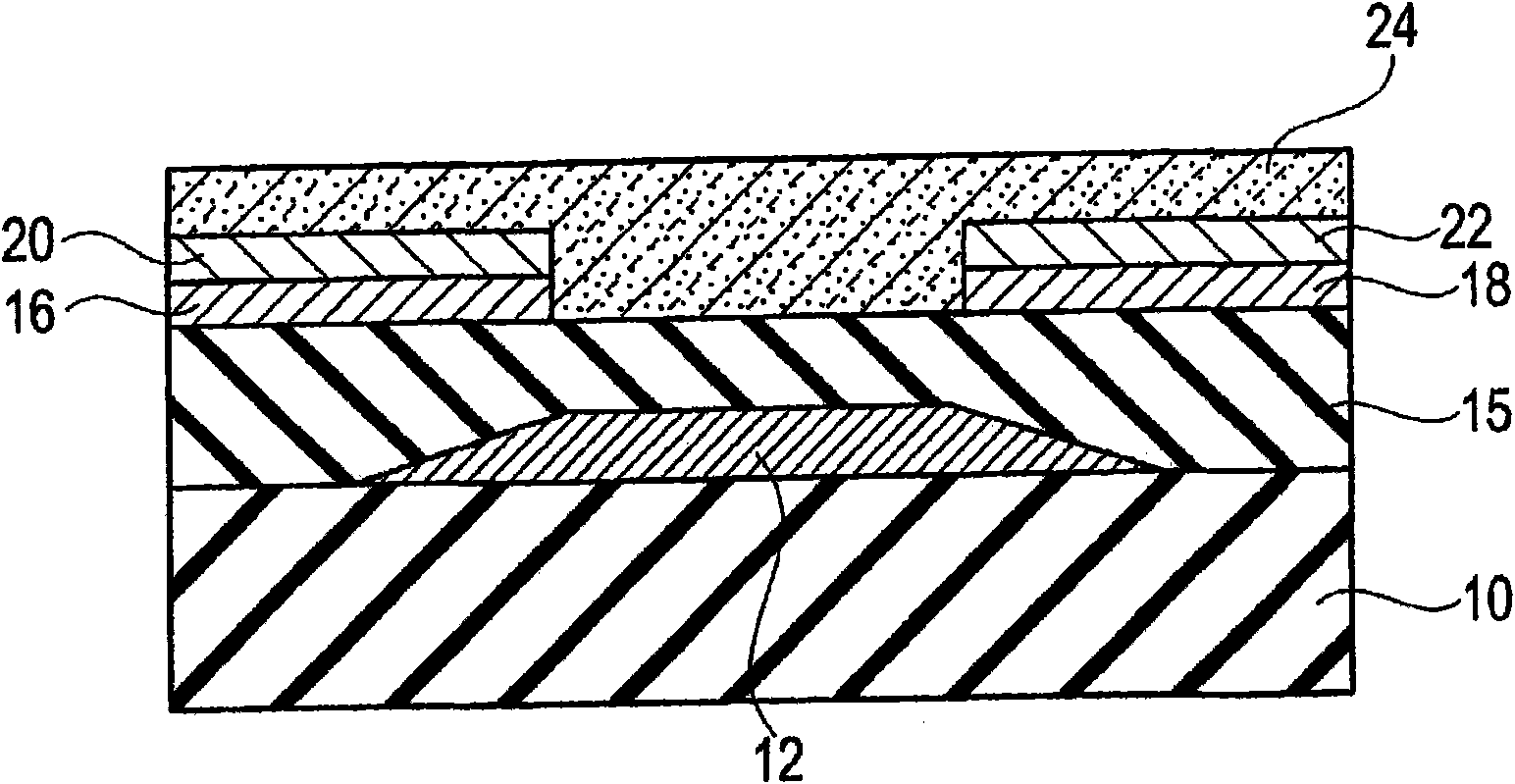

[0148] Figure 8 A schematic cross-sectional structure of the organic semiconductor device according to the second embodiment of the present invention is shown. also, Figure 9 and Figure 10 The drain currents I of the organic semiconductor device according to the second embodiment of the present invention are respectively shown D - Drain voltage V D Characteristic example, drain current I D - Gate voltage V G Feature example.

[0149] like Figure 8 As shown, the organic semiconductor device according to the second embodiment of the present invention has a structure of an organic thin film transistor including: a substrate 10 ; a gate electrode 12 provided on the substrate 10 ; a gate insulator provided on the gate electrode 12 film 15; the gate insulating film 170 provided on the gate insulating film 15; the source electrode (16, 20) and drain electrodes (18, 22); and an organic semiconductor layer 24 provided between the source electrodes (16, 20) and the drain ele...

no. 3 Embodiment approach

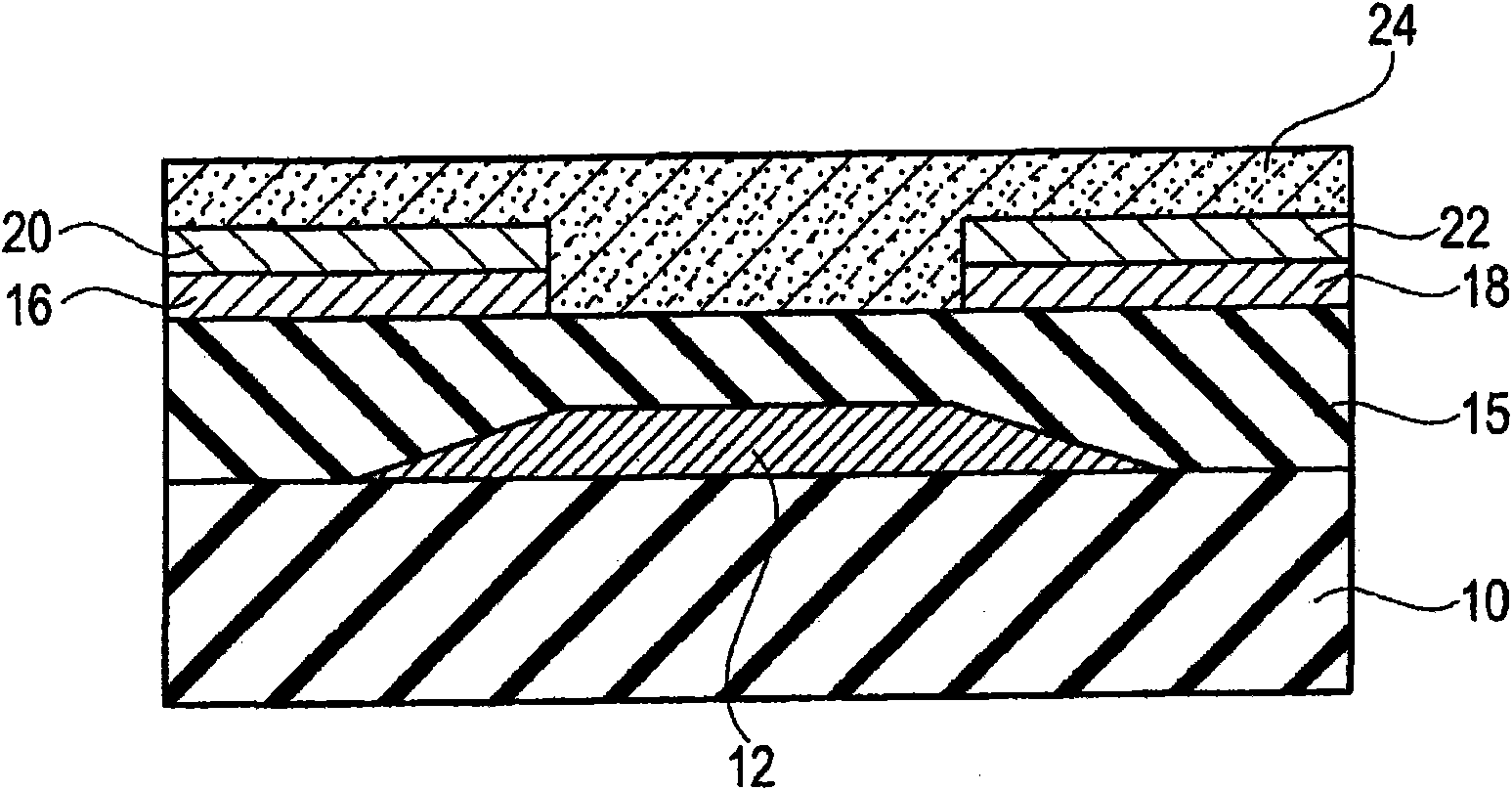

[0185] Figure 15 A schematic cross-sectional structure of an organic semiconductor device according to a third embodiment of the invention is shown.

[0186] like Figure 15As shown, the organic semiconductor device according to the third embodiment of the present invention has an organic thin film transistor, and the organic thin film transistor includes: a substrate 10; a gate 12 disposed on the substrate 10; a gate insulating film 13 disposed on the gate 12; The gate insulating film 15 disposed on the gate insulating film 13; the gate insulating film 170 disposed on the gate insulating film 15; the metal layers 16, 18 and the metal layer 20, disposed on the gate insulating film 170 The source (16, 20) and the drain (18, 22) formed by the laminated structure of 22; The organic semiconductor layer 24.

[0187] In addition, the gate insulating film 15 can be made of, for example, a tantalum oxide film with a thickness of 100 nm or less, and the gate insulating films 13 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com