Sawing ploughing machine

A technology of saw tiller and saw wheel, which is applied in the field of tiller, can solve problems such as failure to achieve ground soil pulverization efficiency, failure to achieve crop growth, etc., and achieve the effects of being beneficial to weeding, light weight and high pulverization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

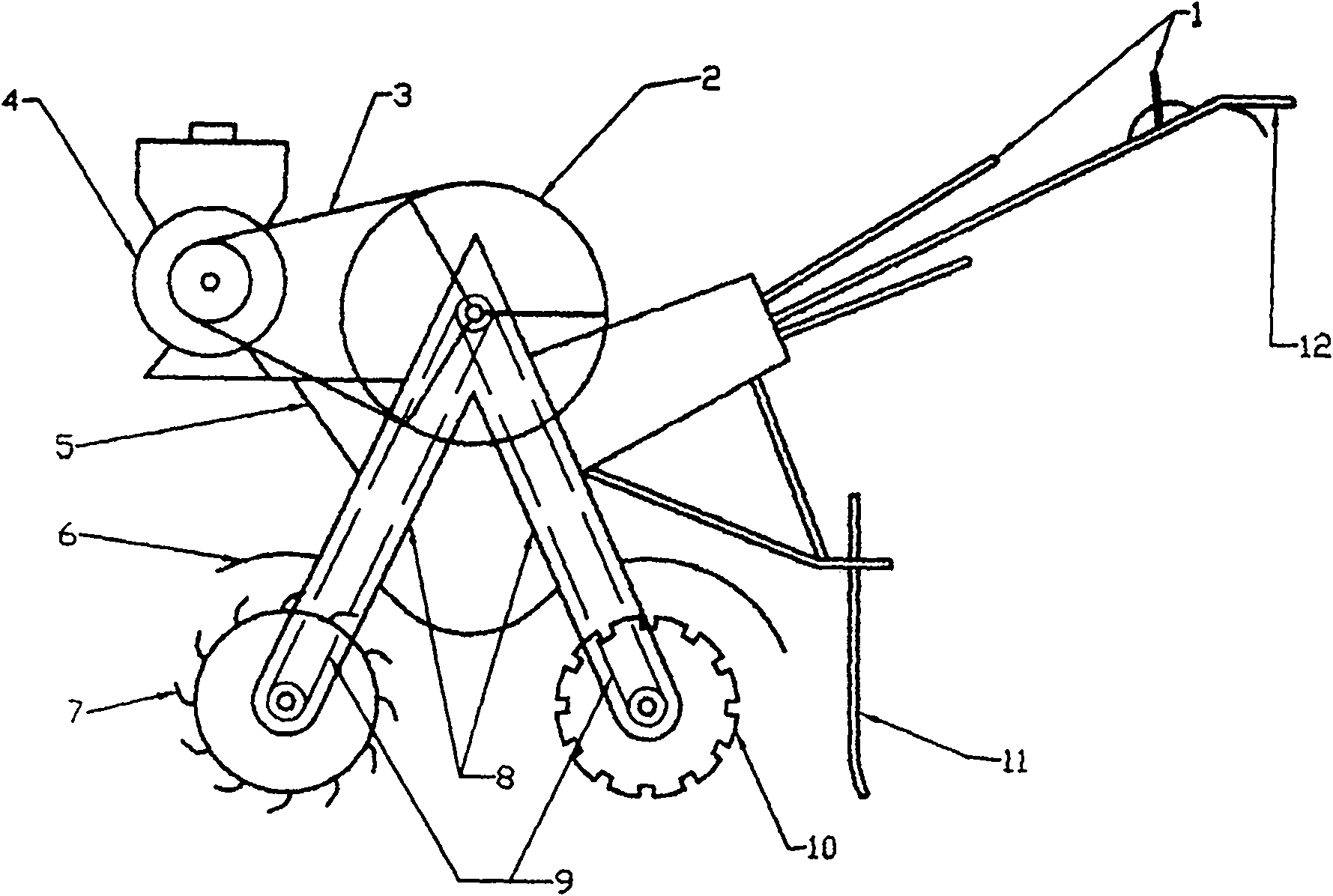

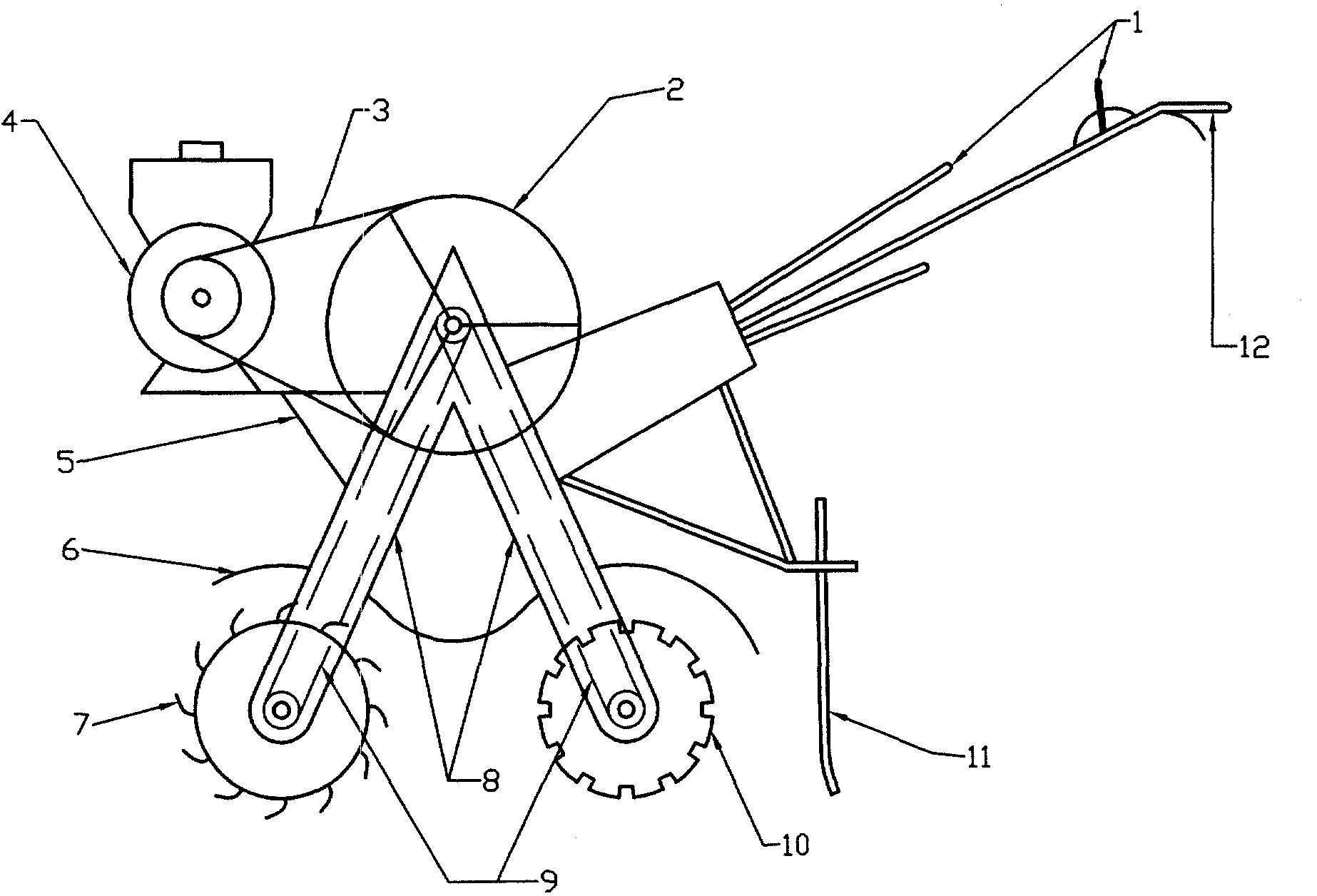

[0007] The main structure of the saw tiller is: the joystick 1 used to control the tillage speed of the saw tiller and the road walking speed, the pulley 2 installed on the top of the inverted English letter ∧-shaped transmission box, and the belt 3 that transmits the engine power to the pulley , the motorcycle engine 4, the bracket 5 supporting the engine, the fender 6 installed on the top of the rotary wheel and the saw wheel, the rotary wheel 7 installed below the transmission box of the inverted English letter ∧ shape, the link wheel and the saw wheel The inverted English letter ∧-shaped transmission box 8 passes the power of the motorcycle engine to the chain 9 of the rotary wheel and the saw wheel through the belt and the pulley, and the saw wheel 10 installed under the inverted English letter ∧-shaped transmission box is used Adjust the adjusting rod 11 of the depth of cultivation, and control the handrail 12 of the walking direction and the depth of cultivation of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com