Profile milling device of camshaft

A profiling milling and camshaft technology, applied in the field of metal cutting, can solve the problems of inconvenient camshaft processing and high processing cost of CNC machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

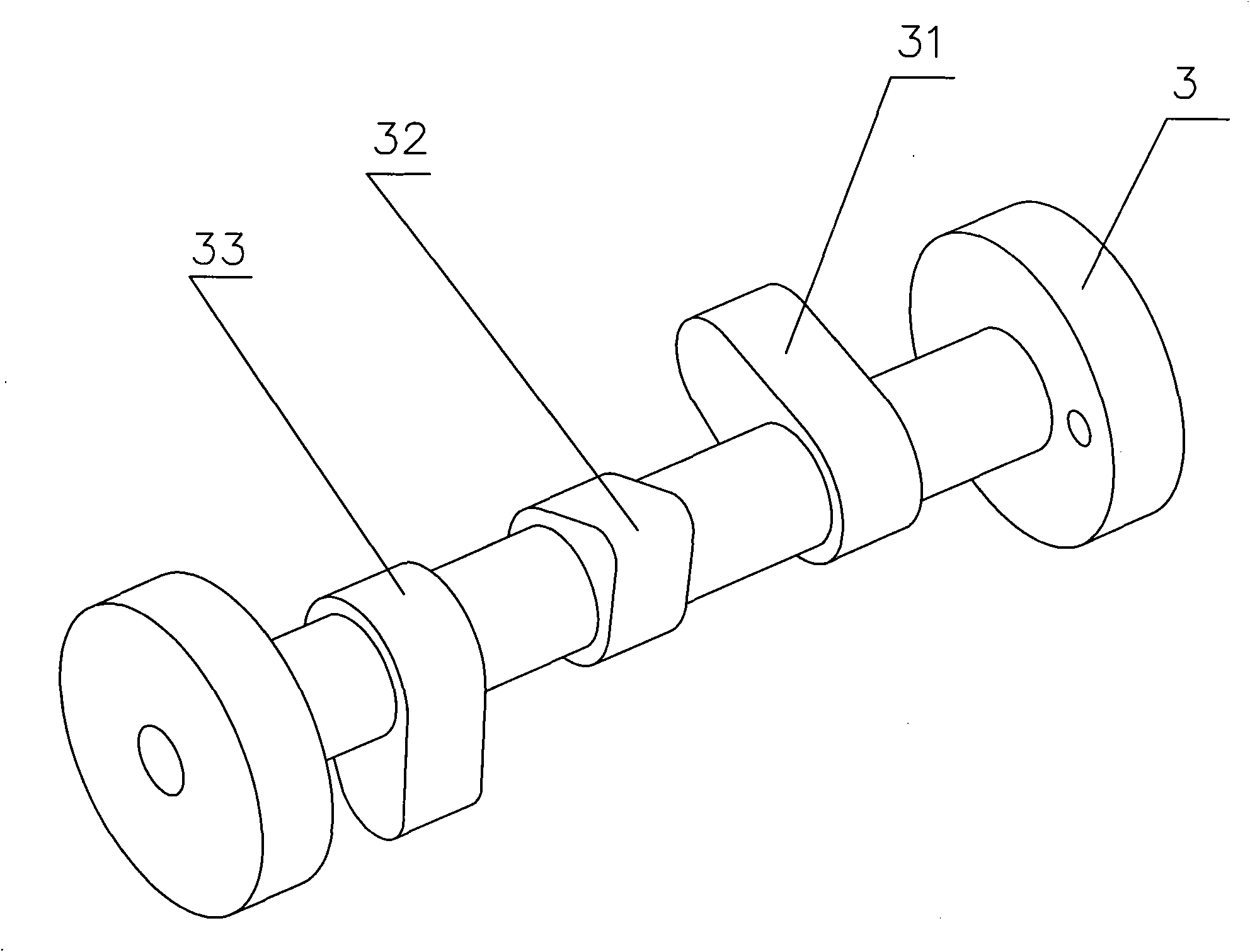

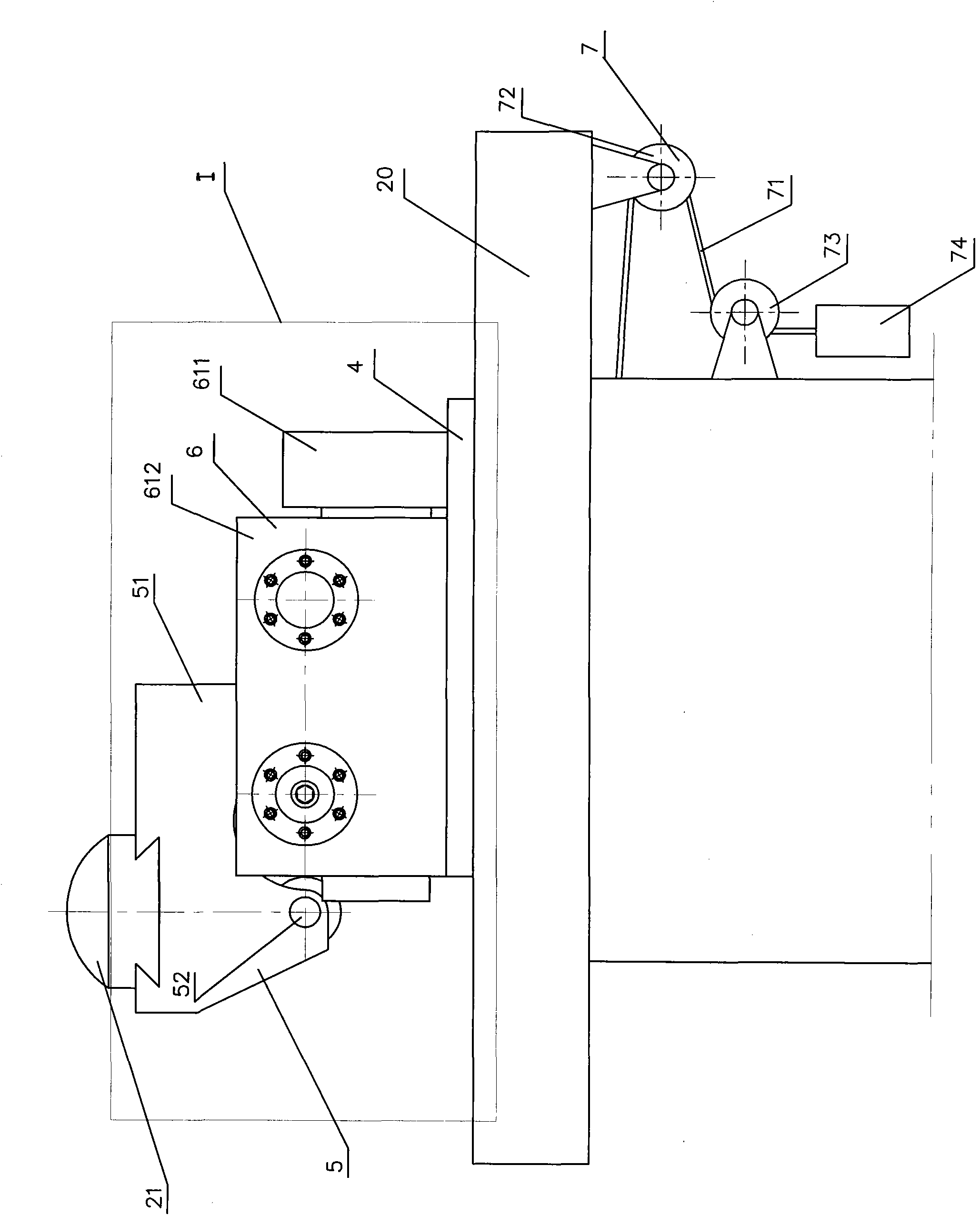

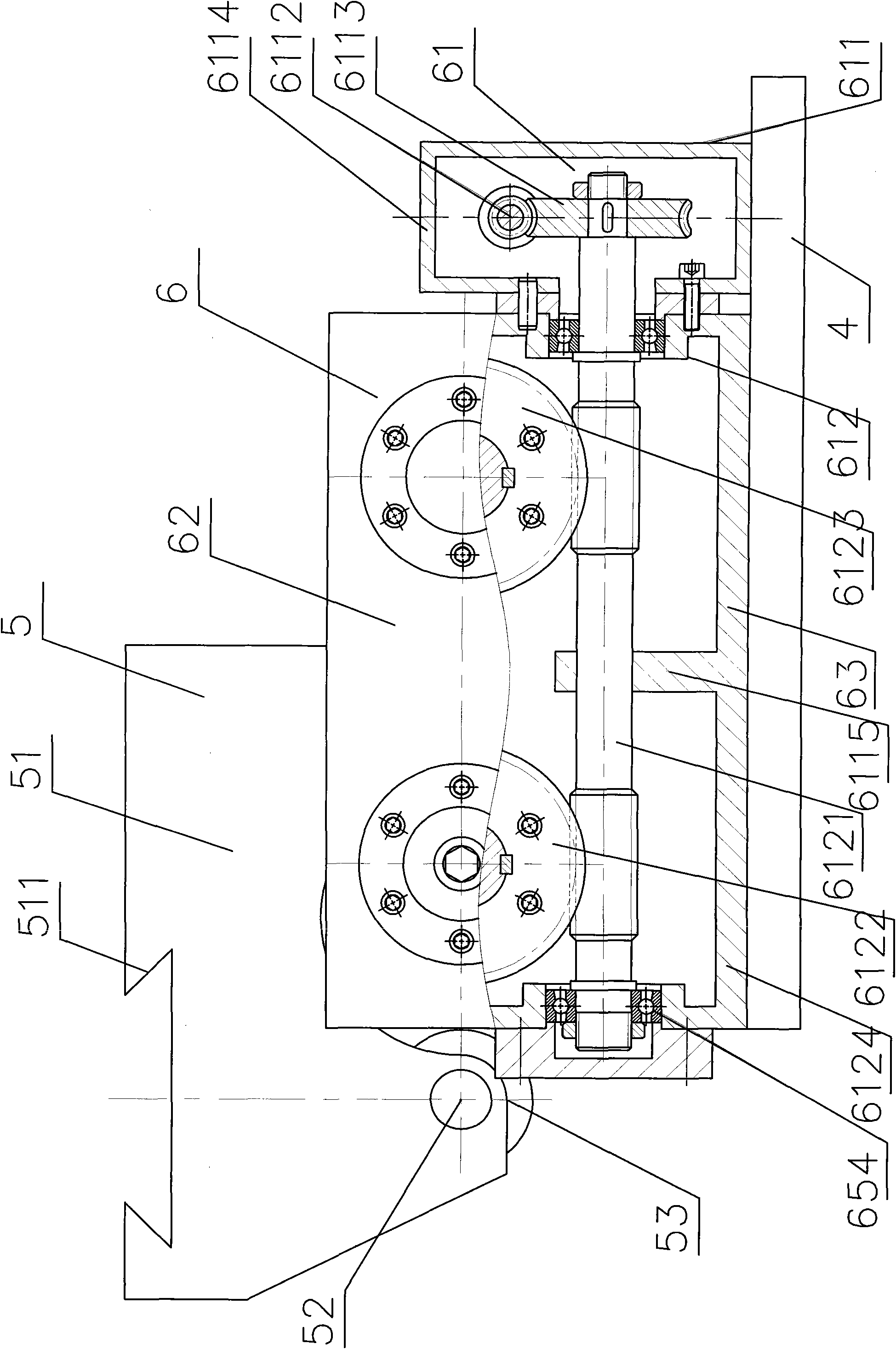

[0023] like Figure 2 ~ Figure 6 As shown, the present invention includes a base 4, a milling mechanism 5, a drive mechanism 6, and a counterweight mechanism 7. The base 4 is fastened on the machine tool table 20 by screws, the milling mechanism 5 is arranged on the machine beam 21, and the drive mechanism 6 is arranged on On the base 4 and in movable contact with the milling mechanism 5, the counterweight mechanism 7 is arranged on one side of the machine tool. The milling mechanism 5 includes a hanger 51, a milling bar 52 with several cylindrical milling cutters 53 at intervals, and a profiling wheel mechanism 54. The upper side of the milling mechanism 5 is fixed to the dovetail head on the lower side of the machine tool beam 21 through the dovetail groove 511 of the hanger. Connect, milling cutter bar 52 and profiling wheel mechanism 54 are arranged side by side un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com