Cutting-off methods of edge gates in plastic moulds and moulds thereof

A technology of plastic molds and large spouts, applied in the field of plastic molds, can solve problems such as easy scratches on plastic parts, failure to replace large spouts, and no molds found, so as to improve production efficiency, increase profits, improve customer satisfaction, and average yield Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

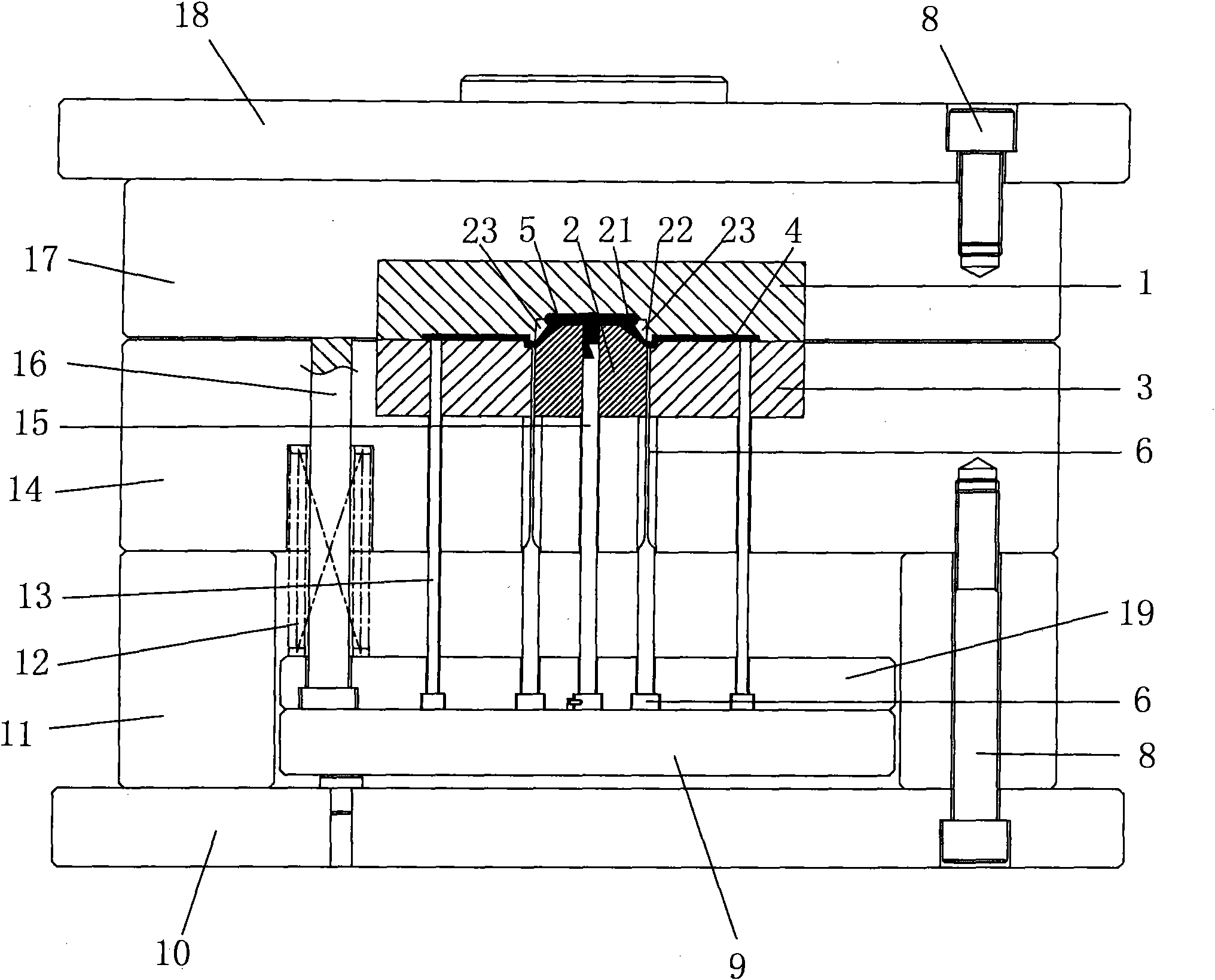

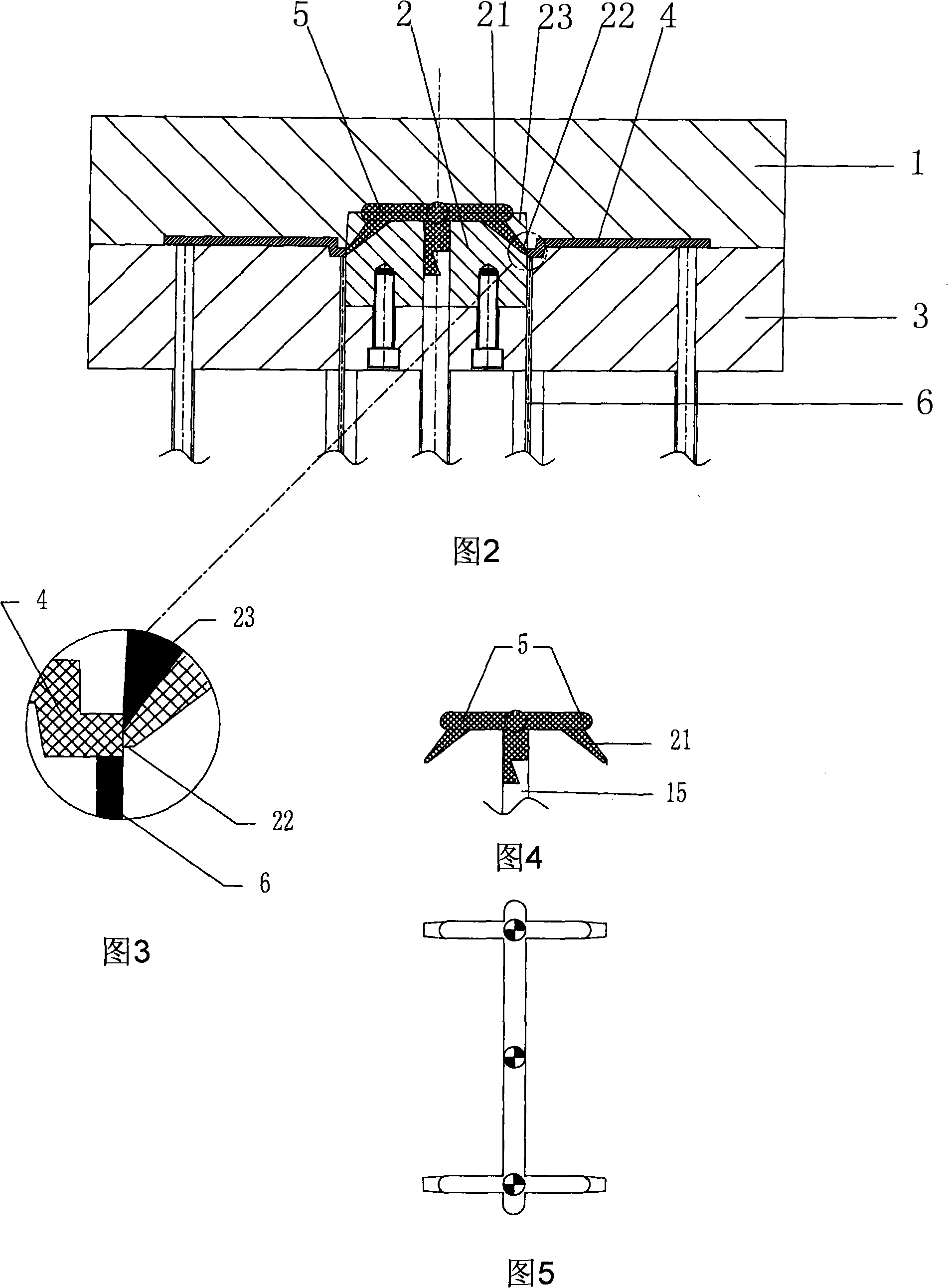

[0085] Embodiment 1; With reference to Figure 2-Figure 5 shown

[0086] The main structure of this example is figure 1 The same, specifically reflected in the structure of the gate insert 2 of the large gate. Among them: the movable mold core 3 is provided with 2 acupuncture points of the large nozzle gate insert, the static mold core 1 is provided with the 2 acupoints of the large nozzle gate insert, and the static mold core is also provided with a main flow channel 5 in the static mold core acupuncture point. Dashuikou gate insert 2 is installed in the acupuncture point between the static mold core 1 and the moving mold core 3, the top surface of the Dashuikou gate insert 2 is provided with a main channel 5, and an undercurrent is provided on the main channel 5 Road 21, (the main channel 5 and the sub-runner 21 form a large nozzle), the large nozzle gate 22 of the sub-runner 21 is a flat gate, and the upper surface of the flat gate forms an acute-angled edge with an inner...

Embodiment 2

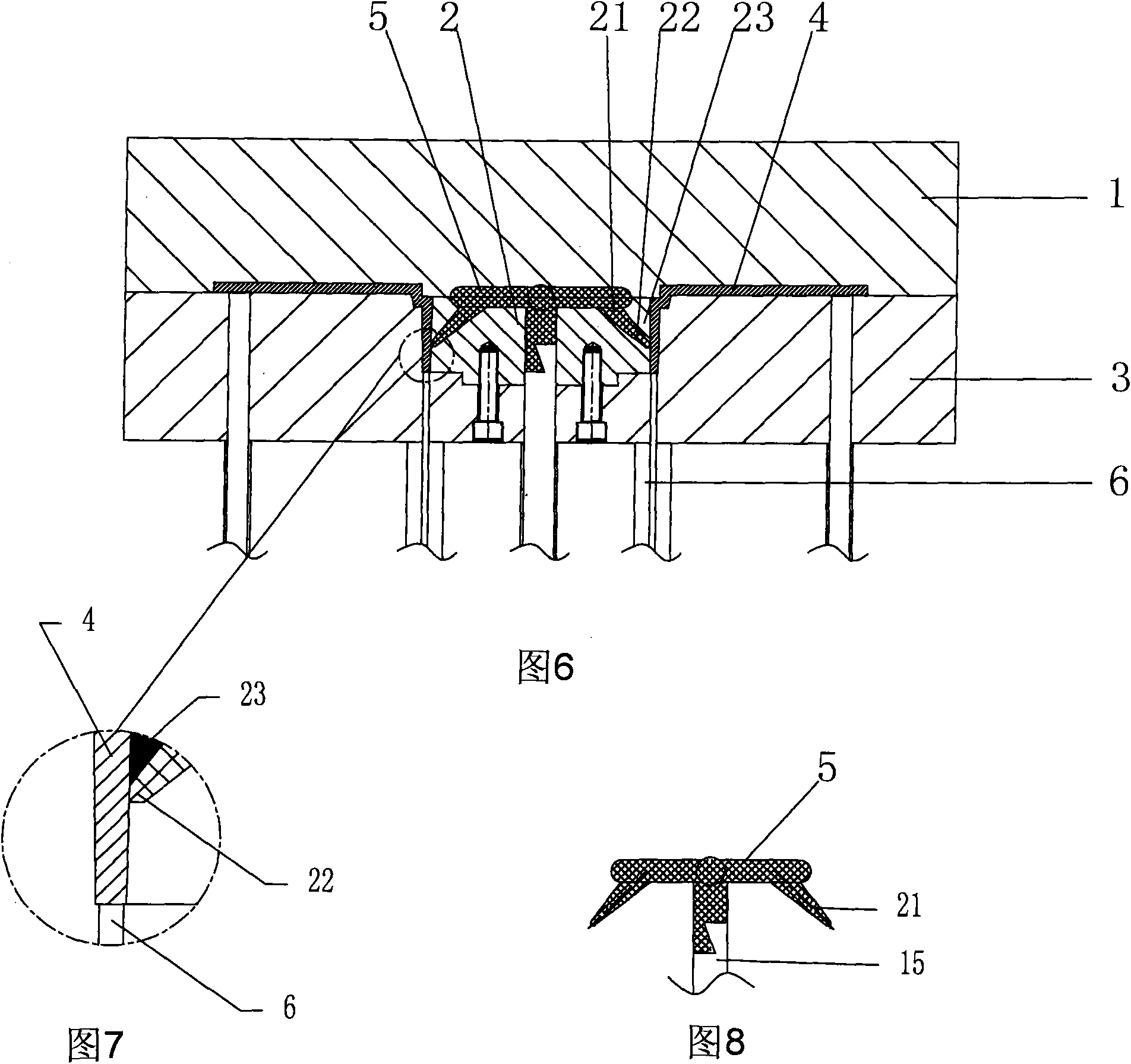

[0089] Embodiment 2; With reference to Figure 6-Figure 9 shown

[0090] The main structure of this example is figure 1 The same, specifically reflected in the structure of the gate insert 2 of the large gate. Among them: in the movable mold core 3, there are 2 acupoints for the large gate gate insert, on the parting surface of the static mold core 1, there is a main channel 5, and the large gate gate insert 2 is installed in the movable mold core 3 In the acupoints, the top surface of the gate insert 2 of the large water inlet is provided with a main channel 5, and an undercurrent channel 21 is arranged on the main channel 5, (the main channel 5 and the undercurrent channel 21 form a large water outlet), and the large water outlet of the undercurrent channel 21 The gate 22 is a flat gate, and the upper surface of the flat gate forms an acute-angled edge with an inner slope. The large gate gate 22 of the underrunner 21 of the main flow channel 5 is connected to the product c...

Embodiment 3

[0093] Embodiment 3; With reference to Figure 10-Figure 13 shown

[0094] The main structure of this example is figure 1 The same, specifically reflected in the structure of the gate insert 2 of the large gate. Among them: the movable mold core 3 is provided with 2 acupoints for the large nozzle gate insert, the static mold core 1 is provided with the 2 acupoints for the large nozzle gate insert, and the mold core 3 is also provided with a main flow channel 5, which is large. The nozzle gate insert 2 is installed in the acupuncture point between the static mold core 1 and the movable mold core 3, the bottom surface of the large gate gate insert 2 is provided with a main channel 5, and an undercurrent channel 21 is provided on the main channel 5 , (the sprue 5 and the sub-runner 21 form a large nozzle), the large nozzle gate 22 of the sub-runner 21 is a flat gate, and the lower surface of the flat gate forms an acute-angled edge with an inner slope, wherein the sprue 5 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com