Step swirling flow vertical shaft

A swirl shaft and ladder technology, which is applied in the field of swirl shafts with high water head and large flow, can solve the problems of increased cavitation and cavitation on the wall surface, difficulty in aeration, and high flow rate, so as to improve the energy dissipation rate and increase the resistance along the water flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

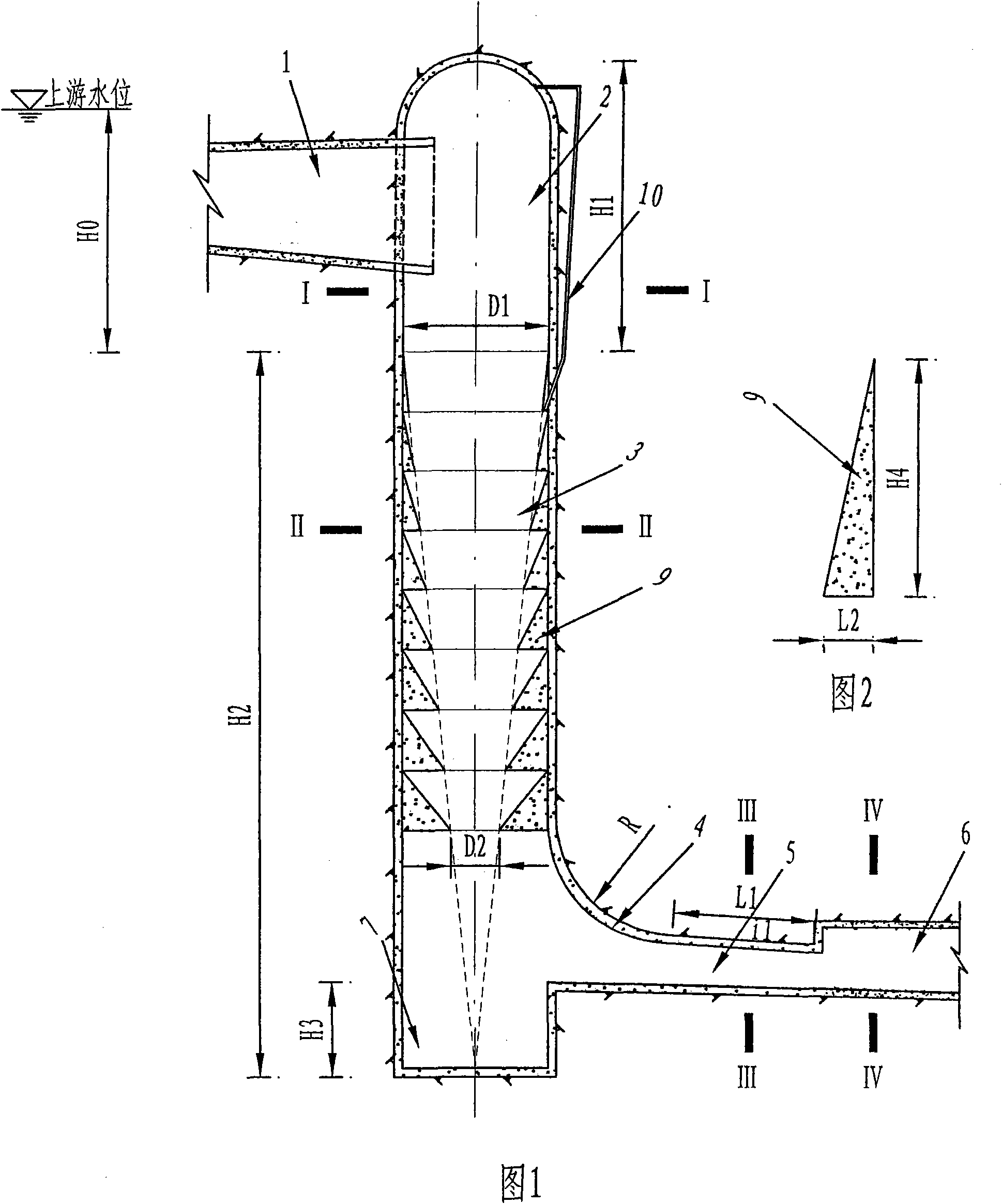

[0026] The stepped swirl shaft in this example is designed according to the spillway tunnel of a hydropower station project. In the case of checking the flood, the design flow of the spillway tunnel is 543m 3 / s, the top elevation is 2495m, and the vertical shaft section with stepped energy dissipators starts to be connected at 2365m, and the floor elevation of the vertical shaft spillway tunnel is 2245m.

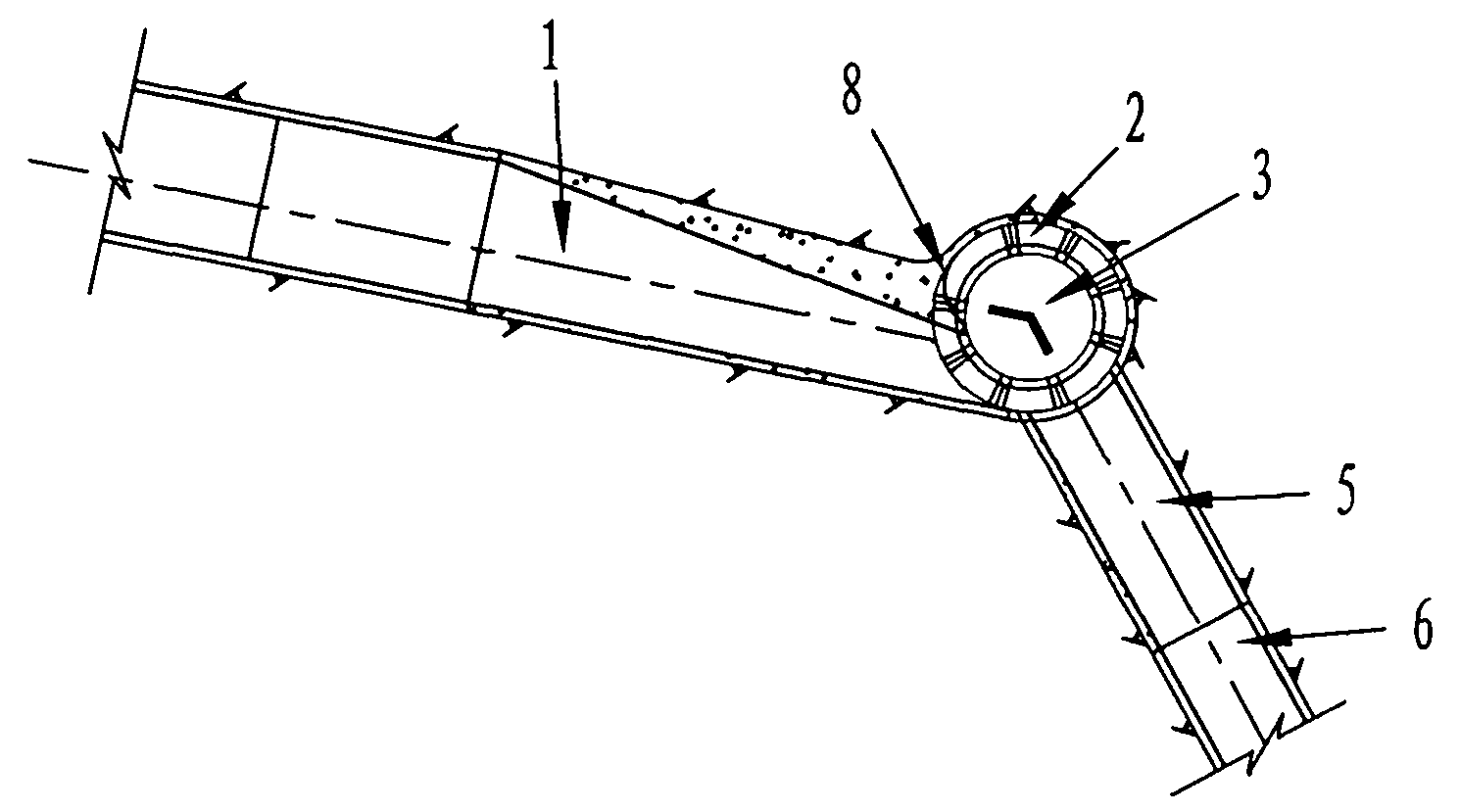

[0027] In this embodiment, the structure of the ladder swirl shaft is as follows figure 1 , Figure 5 As shown, it includes a vortex chamber section 2 and a vertical shaft section 3 connected to the vortex chamber section; the vortex chamber section 2 is provided with a water inlet for tangentially introducing the water flow in the channel 1 into the vortex chamber; the vertical shaft section 3, a stepped energy dissipator 9 is provided on the well wall of the shaft. The stepped energy dissipator 9 is composed of eight steps with the same height. Large and small conical f...

Embodiment 2

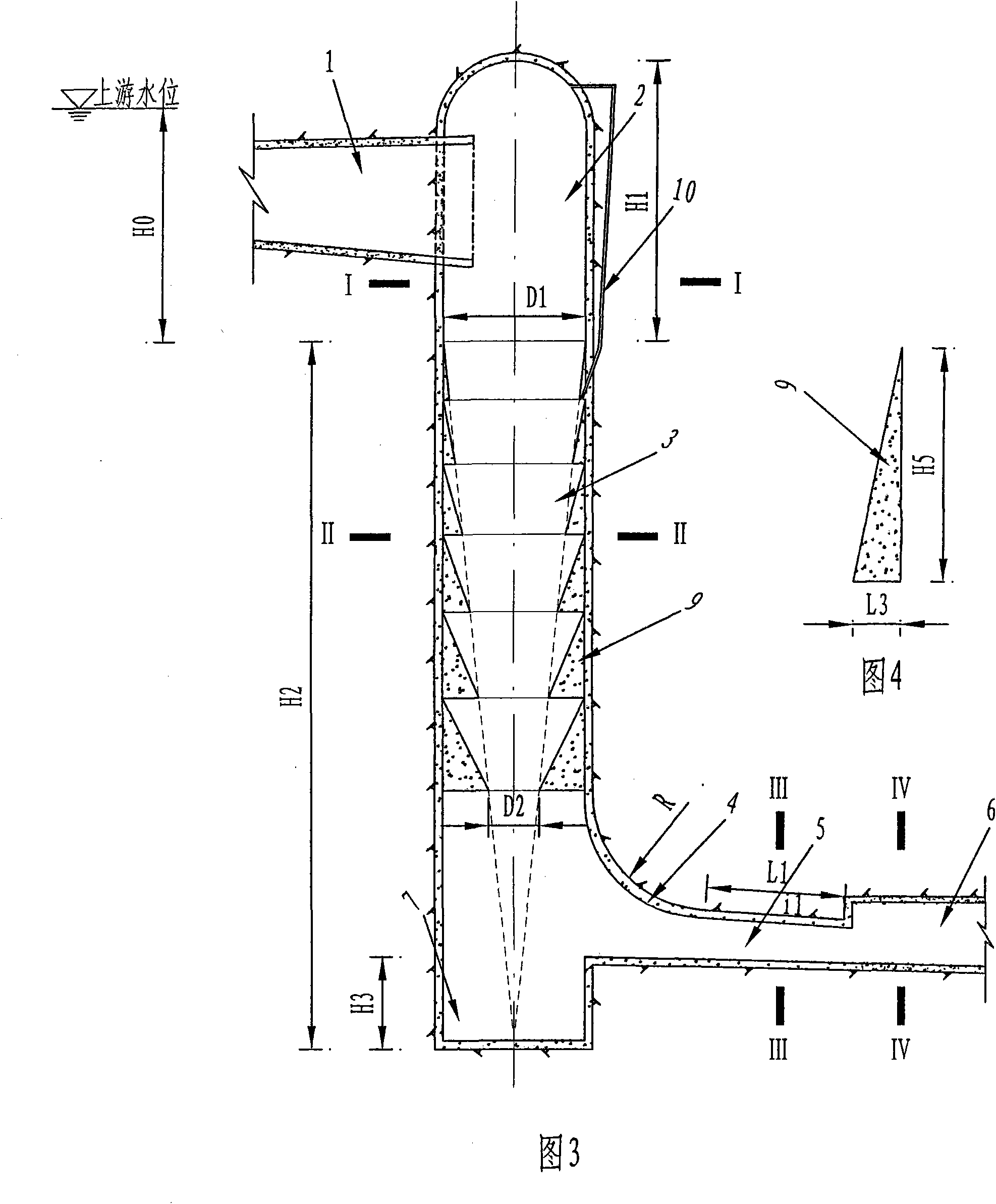

[0031] The stepped swirl shaft in this embodiment is designed according to the spillway tunnel of a hydropower station project. In the case of checking the flood, the design discharge volume of the spillway tunnel is 870m 3 / s, the top elevation is 2425m, and the vertical shaft section with stepped energy dissipators starts to be connected at 2390m, and the bottom plate elevation of the vertical shaft flood discharge tunnel is 2245m.

[0032] In this embodiment, the structure of the ladder swirl shaft is as follows image 3 , Figure 5 As shown, it includes a vortex chamber section 2 and a vertical shaft section 3 connected to the vortex chamber section; the vortex chamber section 2 is provided with a water inlet for tangentially introducing the water flow in the channel 1 into the vortex chamber; the vertical shaft section 3. A stepped energy dissipator 9 is set on the shaft wall of 3. The stepped energy dissipator 9 is composed of seven steps whose heights are proportional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com