Combined planar heat pipe radiator used for cooling light emitting diode (LED)

A technology of flat heat pipes and radiators, applied in cooling/heating devices of lighting devices, indirect heat exchangers, lighting and heating equipment, etc., can solve the problem of poor start-up characteristics of pulsating heat pipes, inappropriate high-power LEDs, heat pipes of heat sinks Small space and other problems, to achieve the effect of improving start-up performance, simple and cheap processing, and increasing overall heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

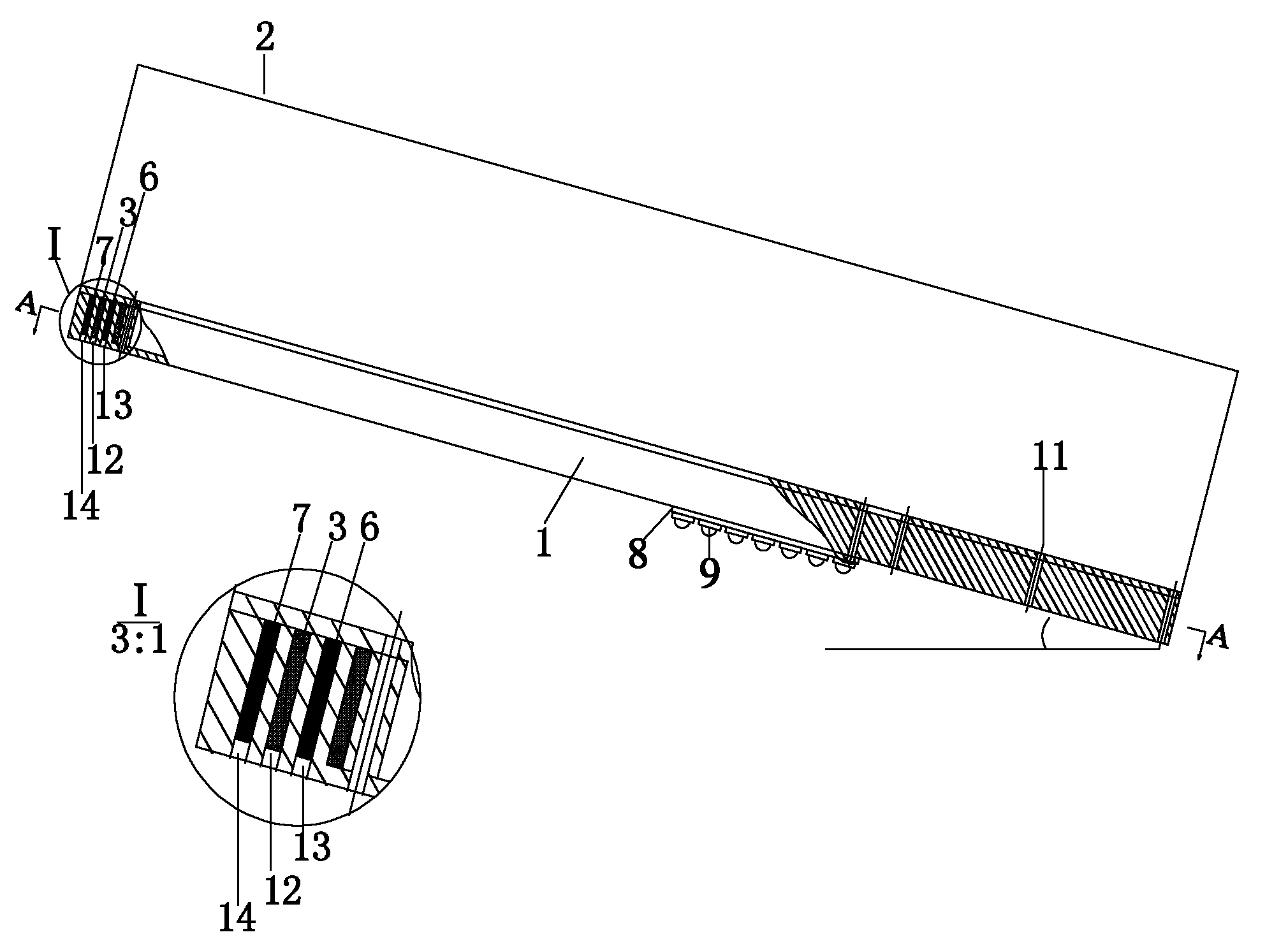

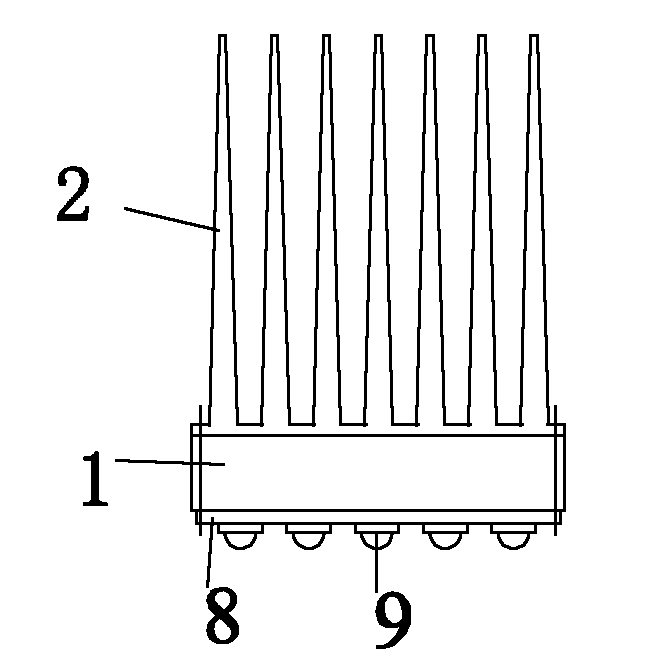

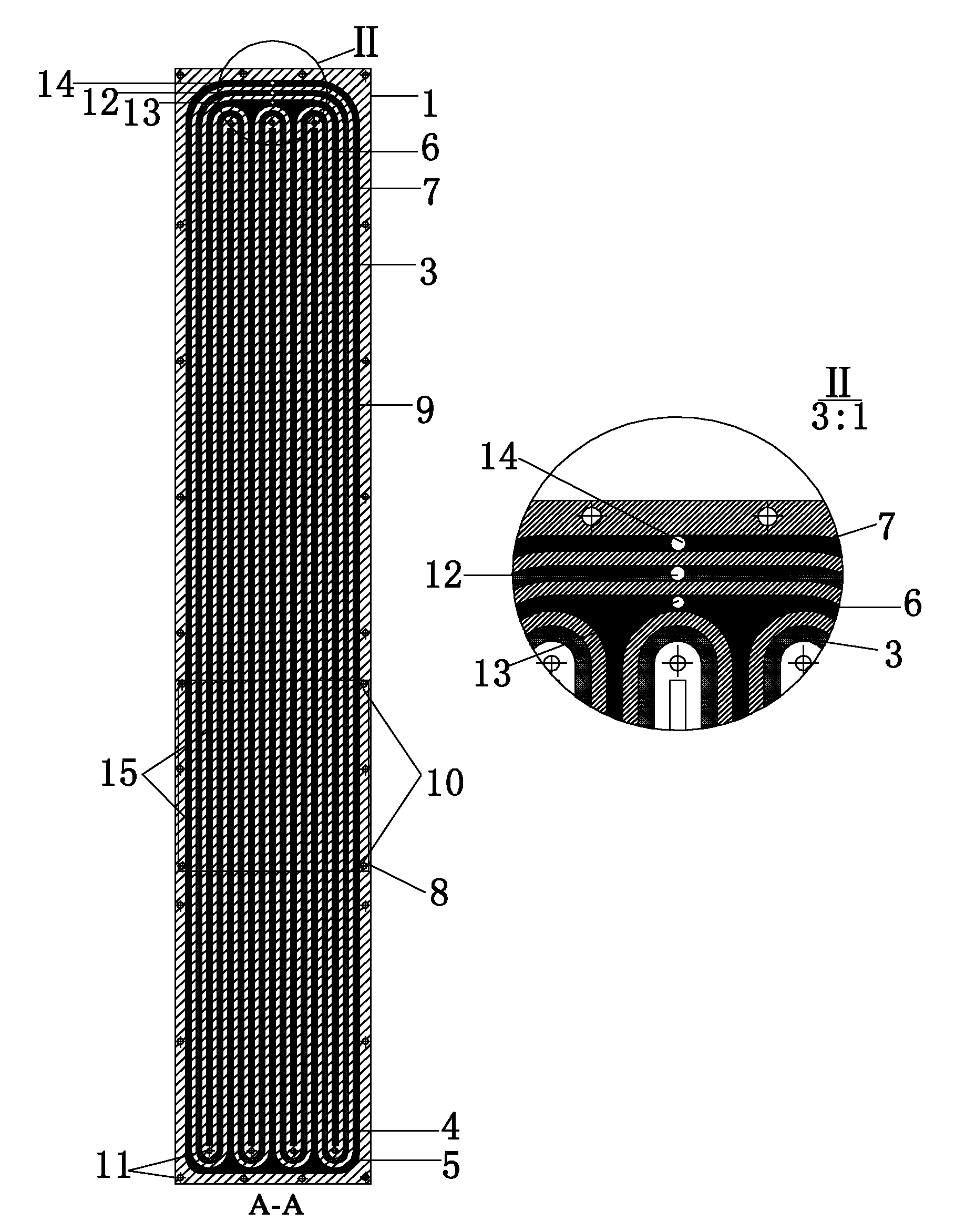

[0025] like figure 1 and figure 2 As shown, this embodiment includes: aluminum plate 1, die-cast heat pipe group channel fin cover plate 2, pulsating heat pipe channel 3, inner wire mesh heat pipe group channel 4, outer wire mesh heat pipe group channel 5, inner gravity The heat pipe group channel 6 and the peripheral gravity heat pipe group channel 7, wherein: the upper and lower ends of the aluminum plate 1 are respectively fixedly connected with the LED substrate 8 and the die-cast heat pipe group channel fin cover plate 2, the pulsating heat pipe channel 3, the inner surrounding wire Mesh heat pipe group cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com