Process for filling colloid into storage battery

A storage battery and glue filling technology, which is applied in battery components, secondary battery manufacturing, circuits, etc., can solve the problems of difficulty in controlling the uniformity of dispersion, low silica content, electrolyte gel, etc., and achieve fast filling process , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

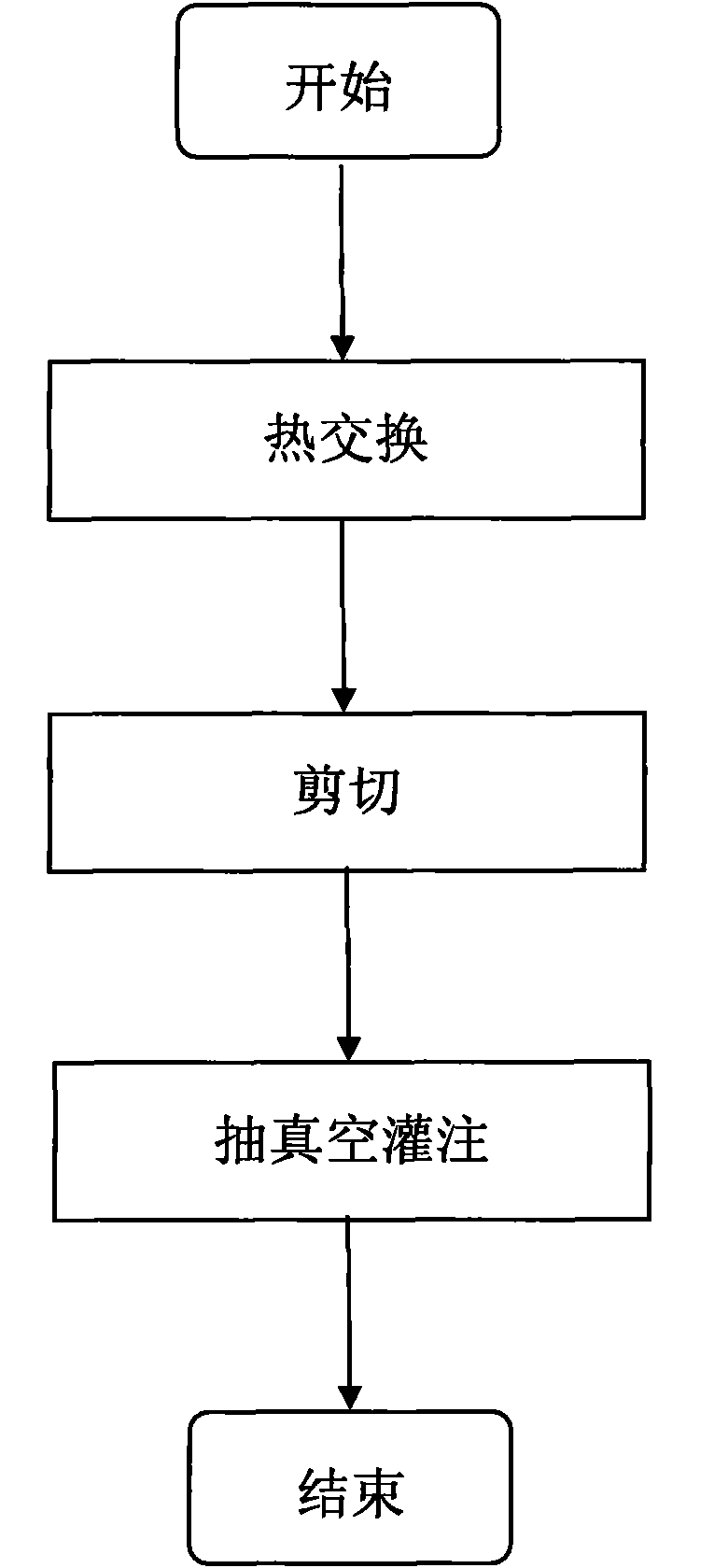

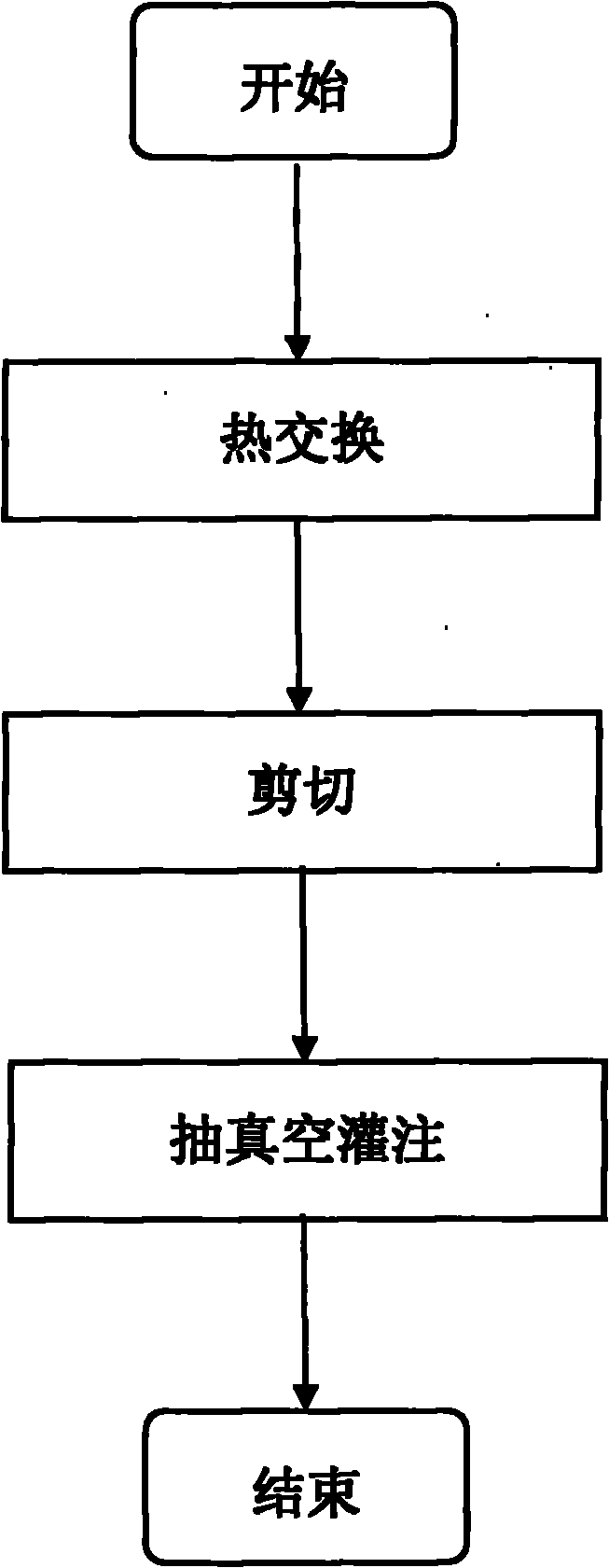

[0018] Such as figure 1 As mentioned above, the battery glue filling process includes the following steps in sequence:

[0019] a) Heat exchange: heat exchange the colloidal electrolyte to a range of 0-45°C and then keep the temperature constant; and control the viscosity of the colloidal electrolyte within the range of 10-400000PC.

[0020] b) Shearing: shearing the colloidal electrolyte with a shearing machine; the shearing machine used includes a rotor and a stator arranged outside the rotor, and the stator is a stator with a grid. The relative movement between the rotor and the stator is used to shear the colloidal electrolyte, and the electrolyte is extruded from the grid gap of the stator to form a negative pressure inside the stator, so that the electrolyte can be sucked in from the bottom of the stator to realize continuous shearing of the colloidal electrolyte. The difference between the inner diameter of the stator and the outer diameter of the rotor is within the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com