Strip line filter, and method for manufacturing the same

A filter and stripline technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of filter characteristic variation, yield drop, electrode burr or peeling, etc., to achieve stable filter characteristics and high-quality products. rate, the effect of suppressing component size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, a configuration example of the stripline filter according to the embodiment of the present invention will be described.

[0030] The stripline filter shown here is a bandpass filter. This filter is used in UWB (Ultra Wide Band) communication corresponding to a high frequency band of 4 GHz or higher.

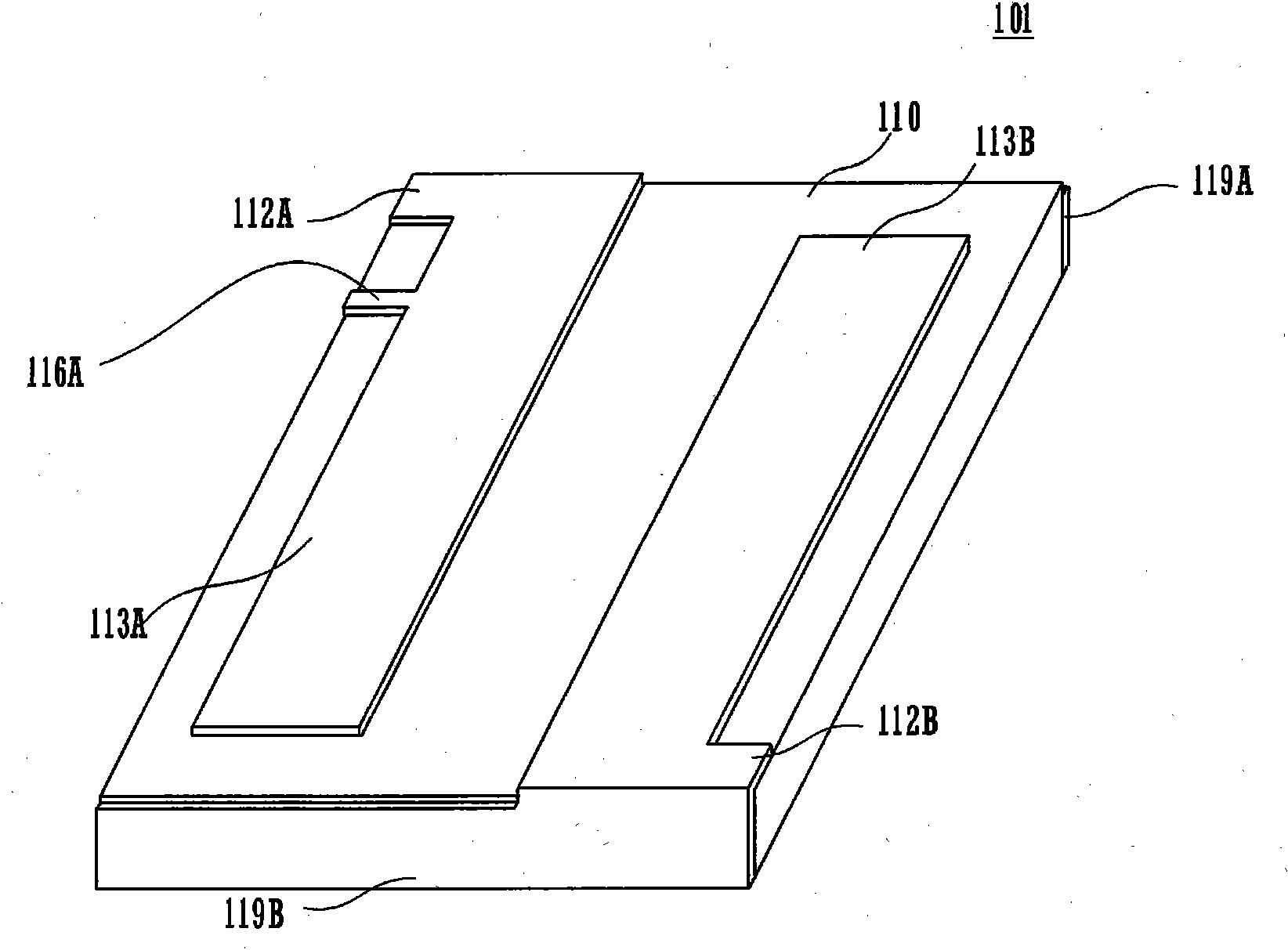

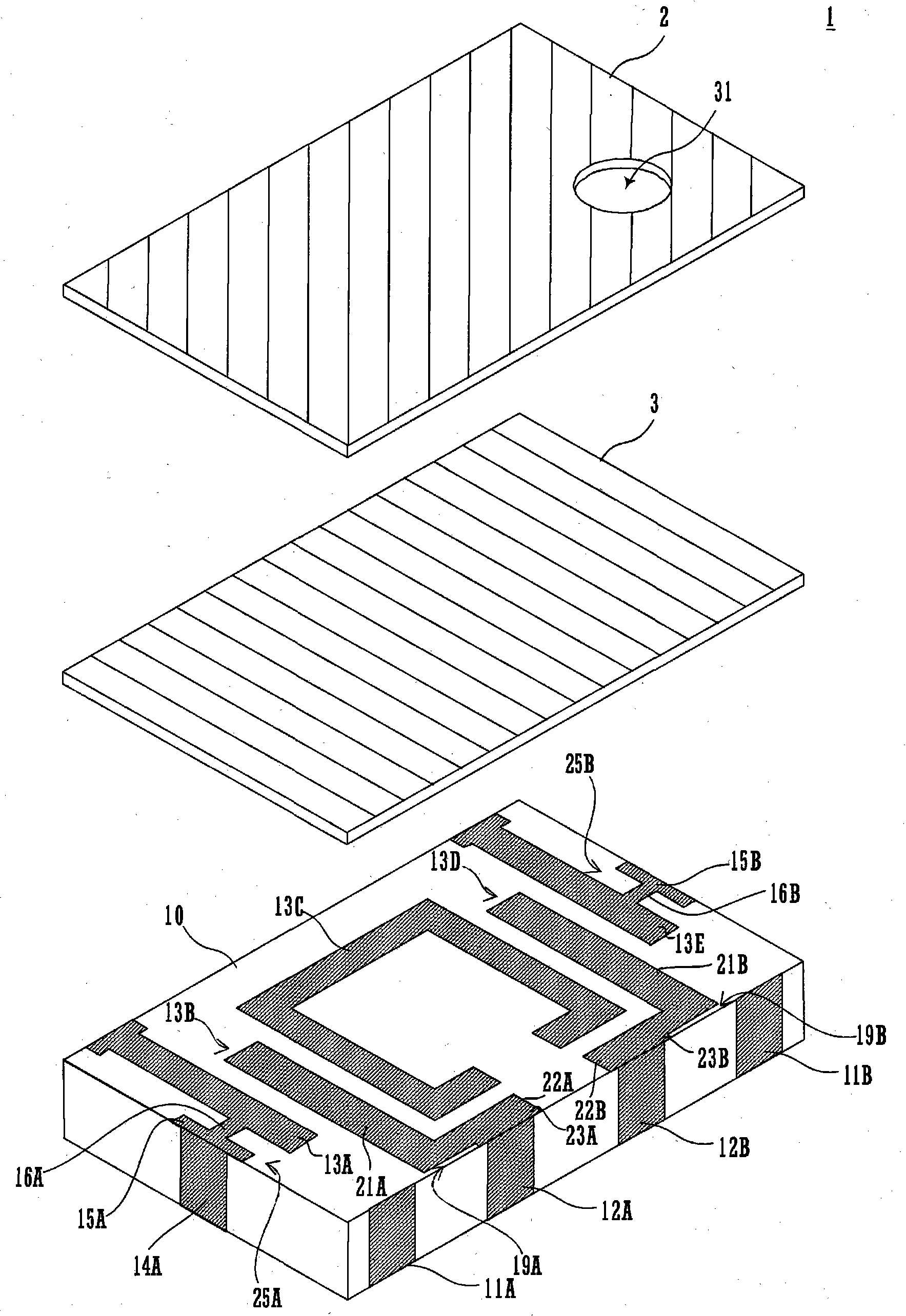

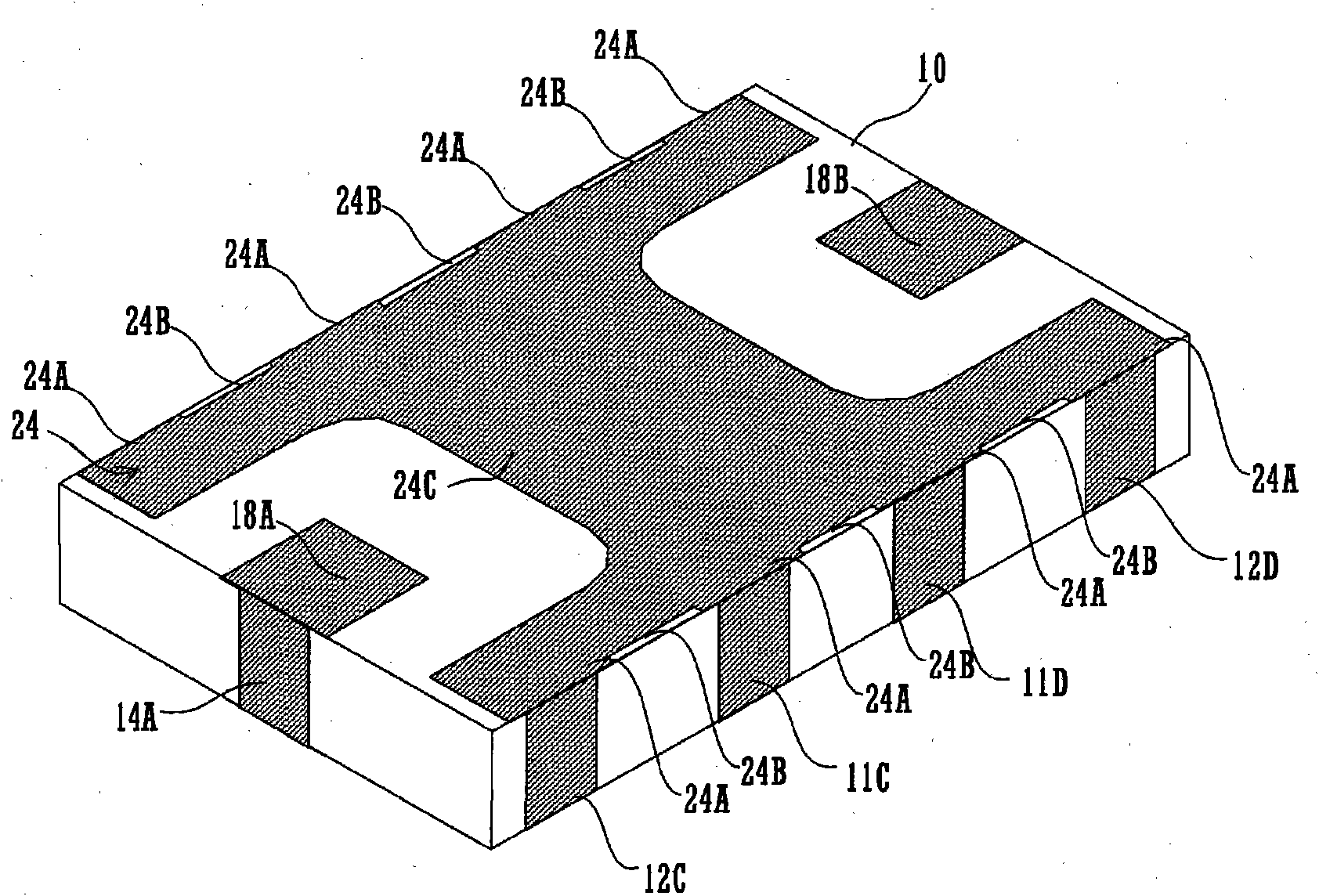

[0031] figure 2 It is an exploded perspective view of the upper surface side of the stripline filter. image 3 It is a perspective view of the lower surface side of the stripline filter.

[0032]The stripline filter 1 has a dielectric substrate 10 and glass layers 2 , 3 . Here, the glass layers 2 , 3 each have a thickness of approximately 15 μm. The glass layers 2 and 3 are laminated on the upper surface of the dielectric substrate 10, and are used for mechanical protection of the stripline filter 1, improvement of weather resistance, and the like. Since the glass layer 2 is laminated on the glass layer 3 , the hole 31 serving as an indicator can be prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com