Method for producing instant mock meat by using isolated soy protein

A technology of soybean protein isolate and vegetarian meat, which is applied in the direction of plant protein processing and texturization to achieve the effect of diversification of color, surface adhesion and degree of fibrosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

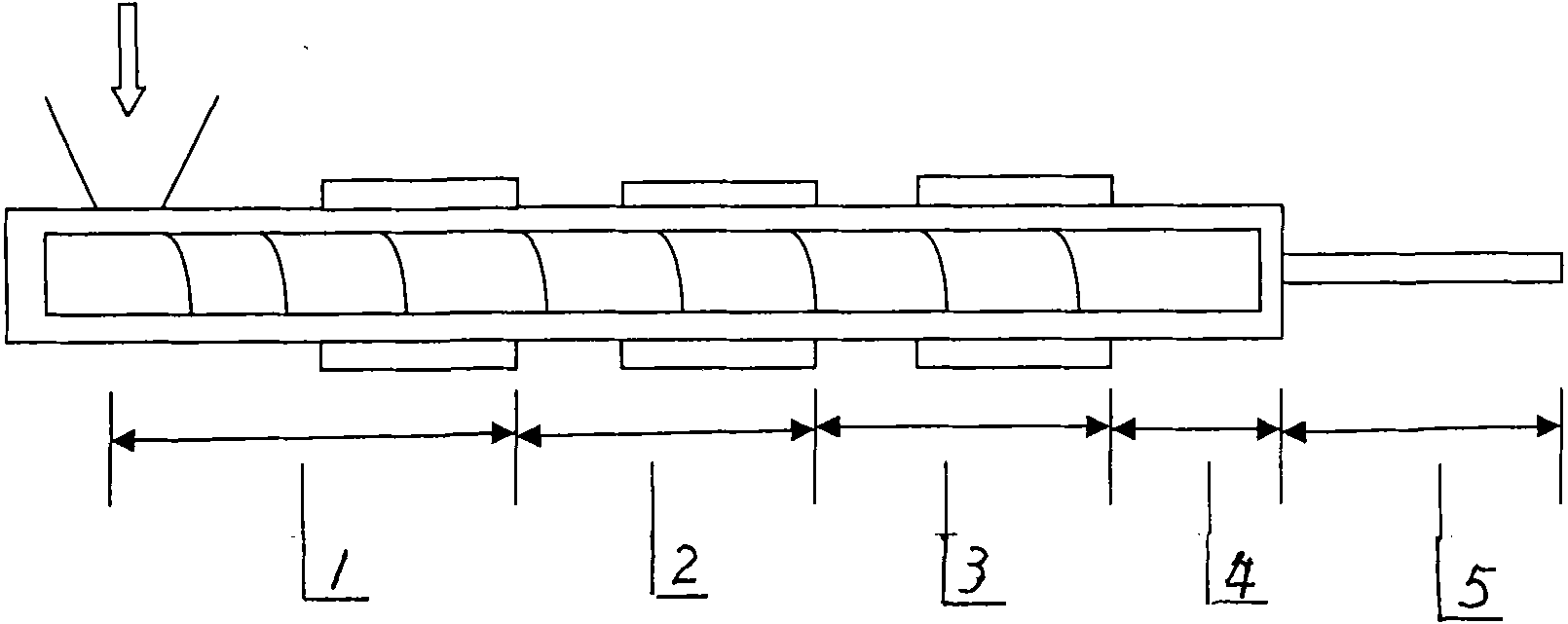

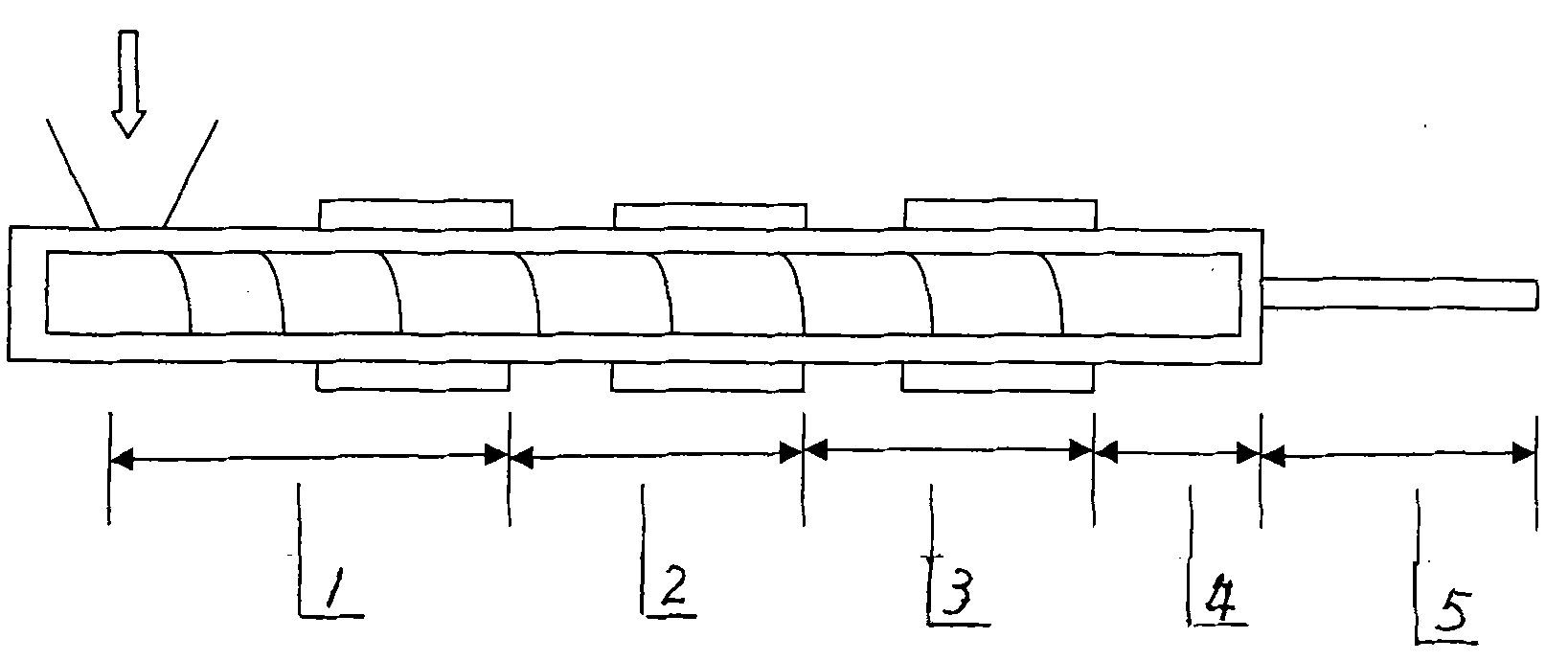

[0041] Weigh 500g soybean protein isolate (purchased from Yifahe Soybean Products Co., Ltd., Tongyu County, Jilin Province) and 200g soluble soybean polysaccharide (purchased from Guangzhou Huahui Biological Industry Co., Ltd.) The screw extruder (Brabender DSE-25 Extruder) carries out high-moisture extrusion texturing, and the constant flow pump is used for material conditioning in the front section of the extruder barrel. By controlling the flow rate of the constant flow pump, the moisture content of the material reaches 60%. Each area of the extruder barrel adopts different temperature settings. According to the order from the feeding end to the product outlet end, the temperature settings of each area are as follows: 80°C----120°C----150°C---135°C-- -70°C. The extrudate is cut into long strips by an online cutting machine, and packed in a food bag as the finished product.

Embodiment 2

[0043] Weigh 500g soybean protein isolate (purchased from Yifahe Soybean Products Co., Ltd., Tongyu County, Jilin Province) and 300g insoluble soybean polysaccharide (purchased from Guangzhou Huahui Biological Industry Co., Ltd.) The screw extruder (Brabender DSE-25 Extruder) carries out high-moisture extrusion texturing, and the constant flow pump is used for material conditioning in the front section of the extruder barrel. By controlling the flow rate of the constant flow pump, the moisture content of the material reaches 65%. Each area of the extruder barrel adopts different temperature settings. According to the order from the feeding end to the product outlet end, the temperature settings of each area are as follows: 80°C----120°C----150°C---135°C-- -70°C. The extrudate is cut into long strips by an online cutting machine, and packed in a food bag as the finished product.

Embodiment 3

[0045]Weighed 500g soybean protein isolate (purchased from Yifahe Soybean Products Co., Ltd., Tongyu County, Jilin Province), 100g soluble soybean polysaccharide (purchased from Guangzhou Huahui Biological Industry Co., Ltd.), 250g insoluble soybean polysaccharide (purchased from Guangzhou Huahui Biological Industry Co., Ltd.) Hui Biological Industry Co., Ltd.), first mix the soluble soybean polysaccharide with the insoluble soybean polysaccharide, and then mix the soybean polysaccharide mixture with soybean protein isolate, and apply the German Brabender twin-screw extruder (Brabender DSE-25 Extruder) For high-moisture extrusion texturing, a constant-flow pump is used for material conditioning at the front of the extruder barrel. By controlling the flow rate of the constant-flow pump, the moisture content of the material can reach 63%. Each area of the extruder barrel adopts different temperature settings. According to the order from the feeding end to the product outlet end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com