Alumina membrane coated activated carbon and preparation method thereof

A technology of alumina film and activated carbon, which is applied in chemical instruments and methods, catalyst carriers, and other chemical processes, can solve the problems of reduced catalyst activity, smaller pore size, and lower porosity, so as to improve mechanical strength and simplify the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Aluminum isopropoxide was hydrolyzed at 80°C for 1 hour, nitric acid was added, refluxed at 90°C for 12 hours, and then kept at 90°C in air for 2 hours to obtain a stable alumina sol. Wherein, the mol ratio of aluminum isopropoxide and water is 1: 100, and the mol ratio of aluminum isopropoxide and nitric acid is 1: 0.07;

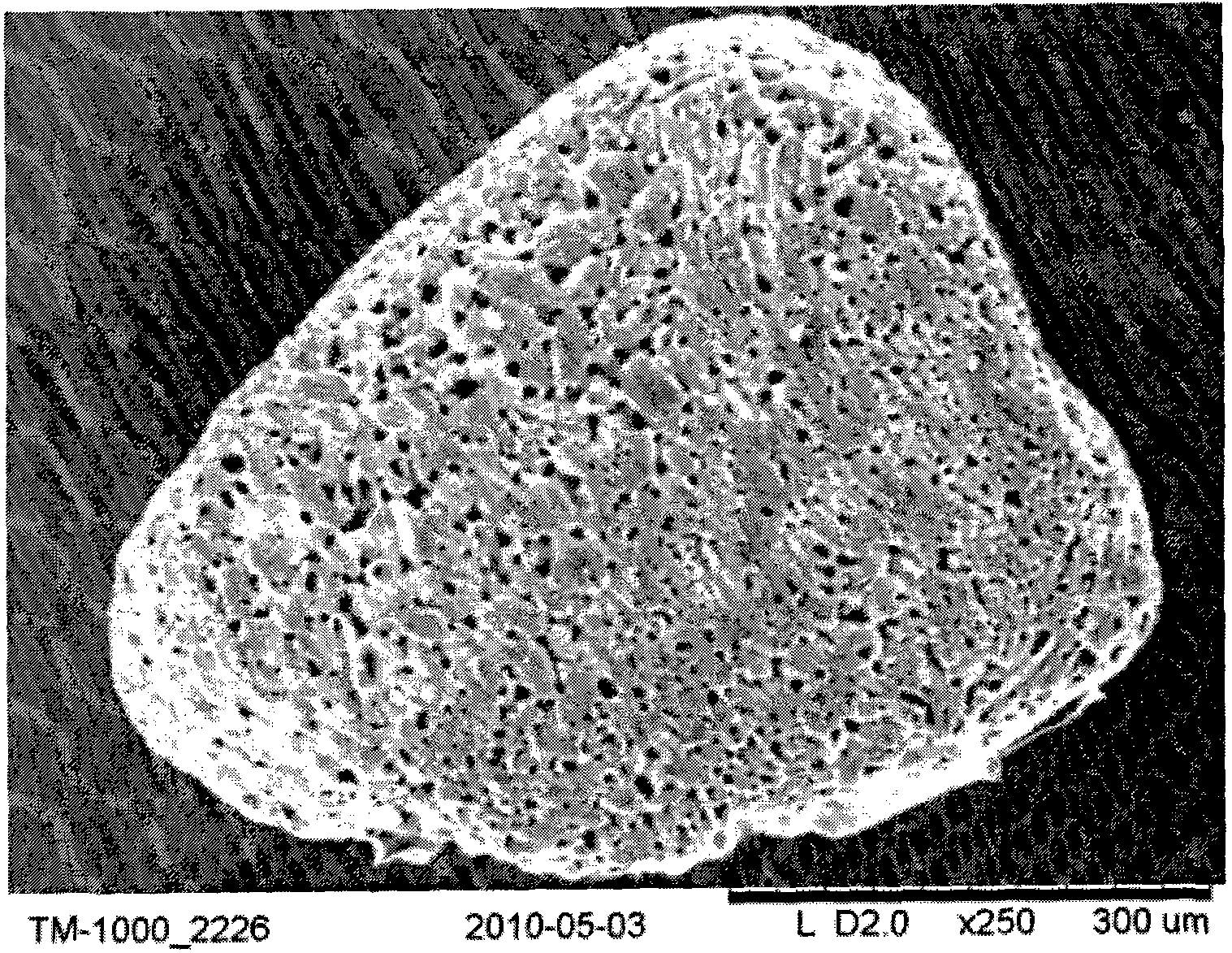

[0019] 2) Mix granular woody activated carbon with alumina sol, soak the slurry for 3 times, then dry at 40°C for 24 hours, heat up to 400°C at a rate of 40°C / h and roast for 4 hours, and then reduce to 40°C at a rate of 40°C / h At room temperature, alumina film-coated granular wood activated carbon was obtained (see figure 1 ), the thickness of the aluminum oxide film is 10nm.

[0020] The wood activated carbon particles (AC2) coated with aluminum oxide film prepared in this example, compared with the wood activated carbon particles (AC1) before coating, the wear rate (measured according to GBT 12496 [1]. 22-1990 standard) has decreased by 74% ,...

Embodiment 2

[0026] 1) Aluminum isopropoxide was hydrolyzed at 80°C for 1 hour, nitric acid was added, refluxed at 90°C for 12 hours, and then kept at 90°C in air for 2 hours to obtain a stable alumina sol. Wherein, the mol ratio of aluminum isopropoxide and water is 1: 100, and the mol ratio of aluminum isopropoxide and nitric acid is 1: 0.07;

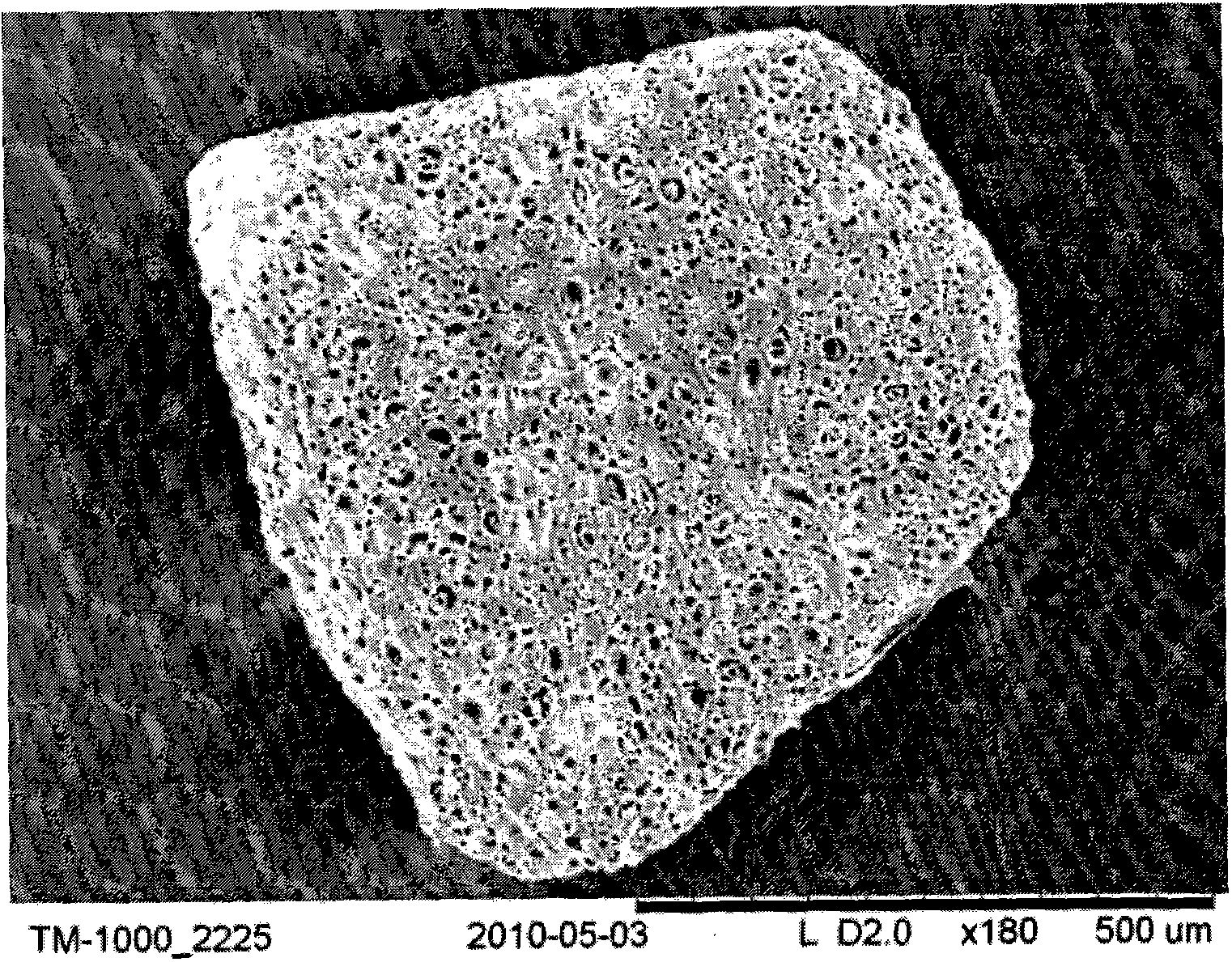

[0027] 2) Mix granular woody activated carbon with alumina sol, dip into slurry 5 times, dry at 40°C for 24 hours, heat up to 400°C at a rate of 40°C / h and roast for 4 hours, then lower to room temperature at a rate of 40°C / h , to obtain granular wood activated carbon coated with alumina film (see figure 2 ), the thickness of the aluminum oxide film is 25nm.

[0028] The wood activated carbon particles (AC3) coated with aluminum oxide film prepared in this example, compared with the wood activated carbon particles (AC1) before coating, the wear rate (measured according to GBT 12496 [1]. 22-1990 standard) has decreased by 77% , it can be seen th...

Embodiment 3

[0033] 1) Aluminum isopropoxide was hydrolyzed at 70°C for 1 hour, nitric acid was added, refluxed at 100°C for 12 hours, and then kept at 100°C in air for 2 hours to obtain a stable alumina sol. Wherein, the mol ratio of aluminum isopropoxide and water is 1: 150, and the mol ratio of aluminum isopropoxide and nitric acid is 1: 0.03;

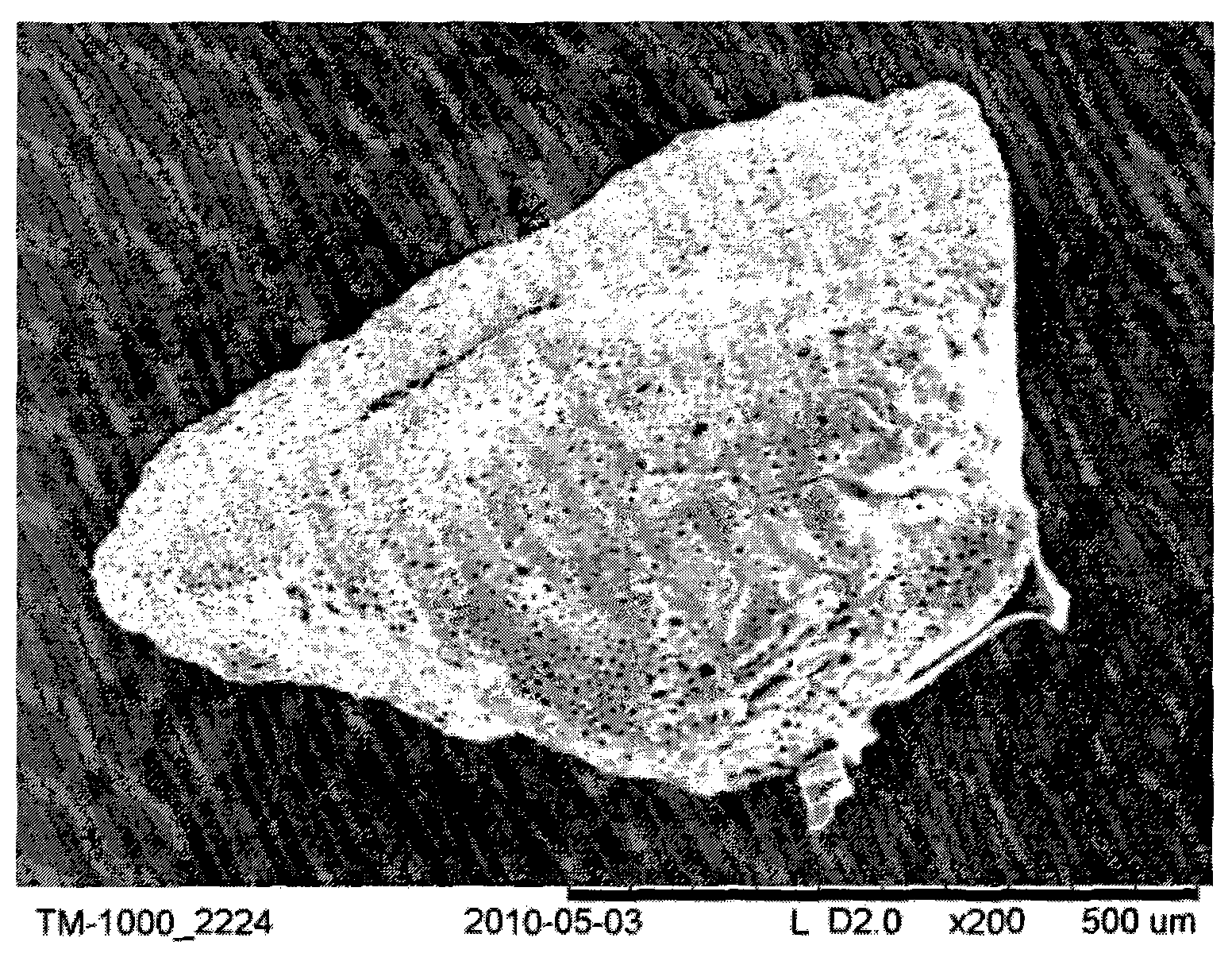

[0034] 2) Mix granular coal-based activated carbon with alumina sol, dip into slurry 7 times, dry at 40°C for 24 hours, heat up to 400°C at a rate of 40°C / h and roast for 4 hours, and then reduce to At normal temperature, the granular coal-based activated carbon coated with alumina film (see image 3 ), the thickness of the aluminum oxide film is 40nm.

[0035] The coal-based activated carbon particles (AC5) coated with aluminum oxide film prepared in this example, compared with the coal-based activated carbon particles (AC4) before coating, the wear rate (measured according to GBT 12496 [1]. 22-1990 standard) is reduced 81%, it can be seen th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com