Water-cooled heater

A heater and water-cooled technology, which is applied in the field of water-cooled heaters, can solve the problems of long distance between the heater and the cooling device, low temperature control accuracy, and product waste, so as to improve the accuracy of temperature control accuracy and facilitate installation and dismantling, the effect of reducing product waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

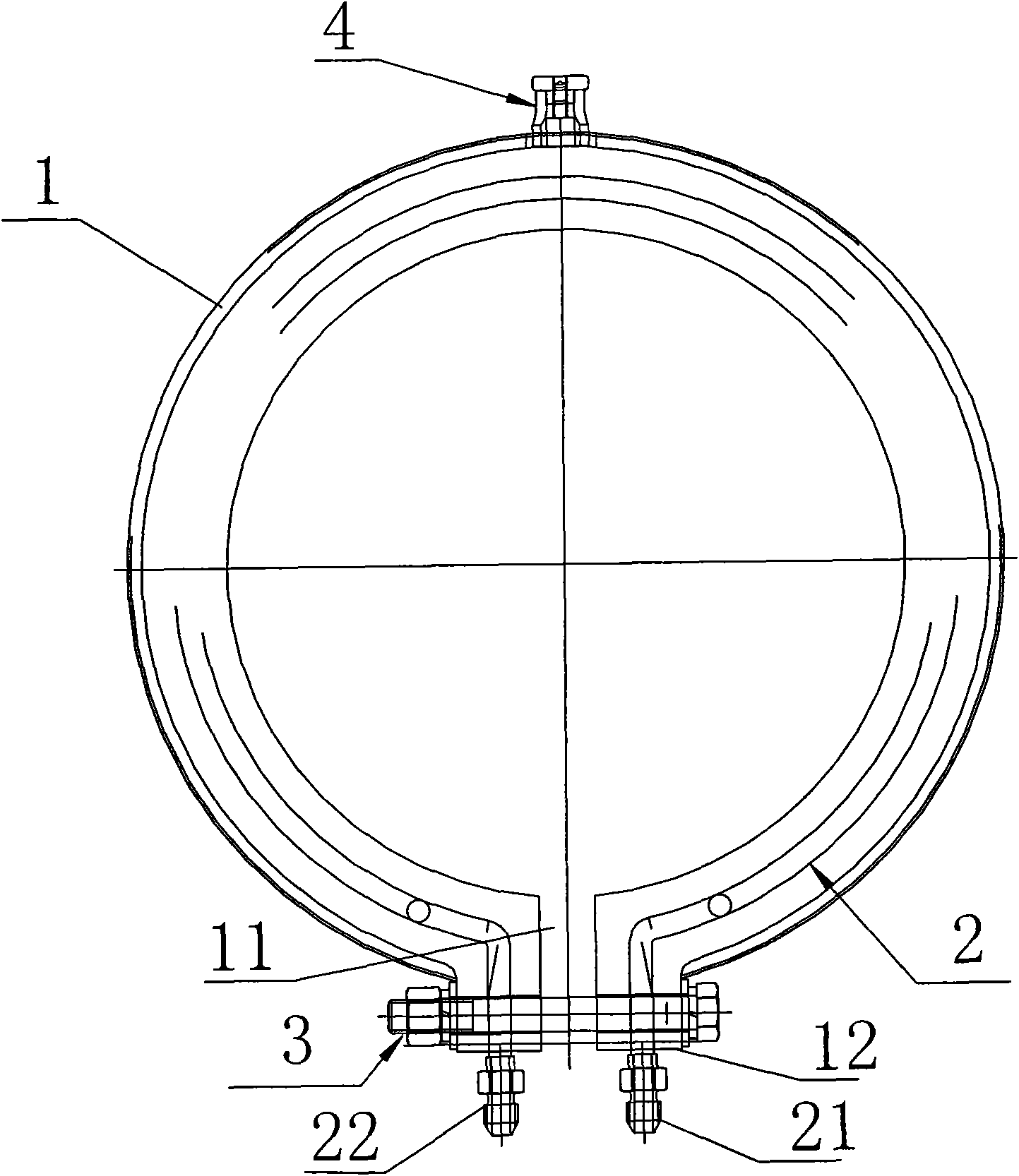

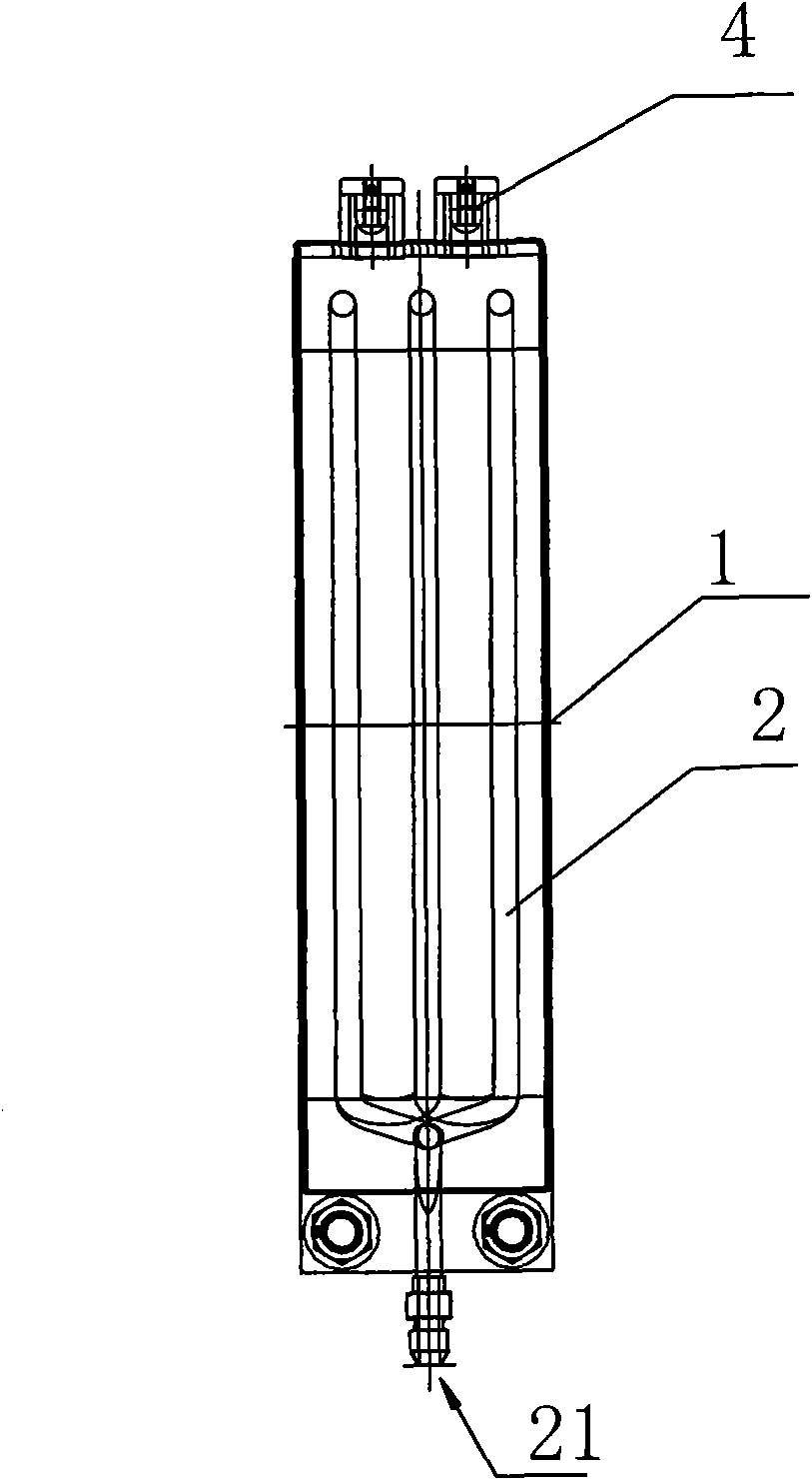

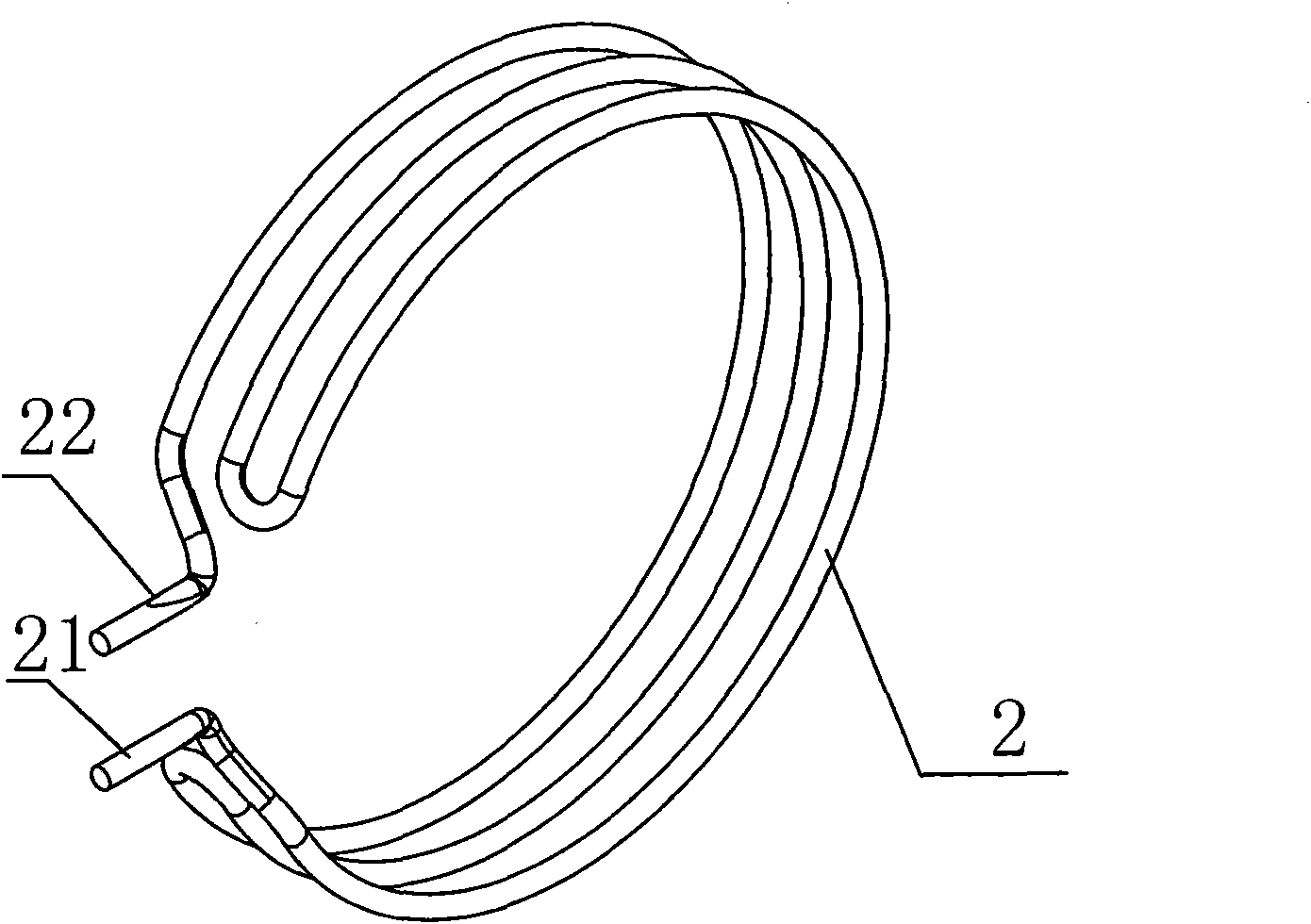

[0019] see figure 1 , the water-cooled heater in this implementation includes an annular heating jacket 1; a built-in cooling pipe 2 for cooling is built in the heating jacket 1, and the built-in cooling pipe 2 is an annular structure and the heating jacket The shape of the body 1 fits and surrounds the heating jacket 1, which forms an annular copper tube with three cooling tubes (see figure 2 with image 3 ). In this embodiment, the built-in cooling pipe 2 and the heating jacket 1 are formed by one-time casting, which is convenient for people to process and use.

[0020] On the heating jacket 1, an open end that can open the annular heating jacket is made. The opening end is made on the heating jacket 1 with an opening 11, and two installation bosses 12 are arranged at the position of the opening 11. Each mounting boss 12 is made with mounting holes for installing locking bolts 3, two mounting holes are provided, and two locking bolts 3 are installed, and the opening heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com