Method for industrially producing silicate phosphate from rice husk carbon

A technology of silicon phosphate and rice husk charcoal, applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of low quality of water glass, easy environmental pollution, high cost, simple and reasonable process method, improved economic value and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Use 7.5 tons of rice husks to prepare silicon phosphate primary solution and high-quality activated carbon.

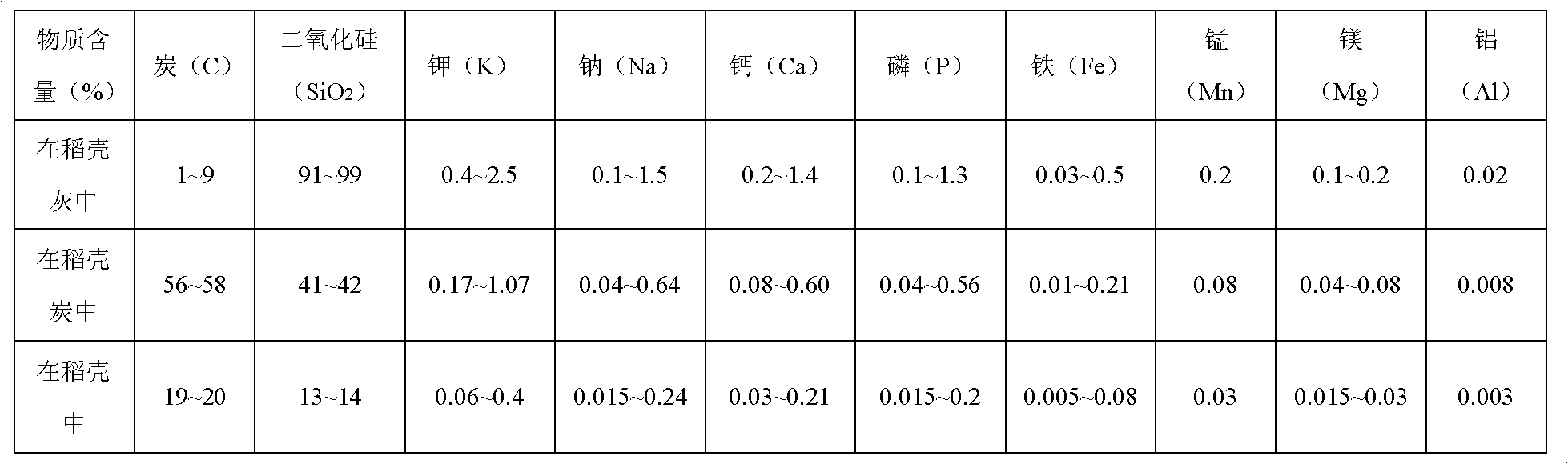

[0041] Step 1: Heat 7.5 tons of rice husk to 550-580°C for smoldering and carbonization to obtain 2.5 tons of rice husk charcoal;

[0042] The second step: add 2.5 tons of the obtained rice husk charcoal into 3.3 tons of phosphoric acid solution with a concentration of 24%, heat to 135-140°C, react for 4-5 hours, filter the solid-liquid mixture obtained after the reaction, and the filtrate is It is silicon phosphate, and after the filter residue is dried, it is primary activated carbon, weighing about 1.8 tons (activated carbon particles contain a large amount of silicon phosphate);

[0043] Step 3: Blend 1.8 tons of the obtained first-grade activated carbon with 180kg of dry rice husk and mix as well as possible, then, seal and pack in a paper bag, seal tightly (without leaking carbon powder) and place it in the activation furnace for activation. ...

Embodiment 2

[0048] Use 7.5 tons of rice husks to produce primary silicon phosphate and high-quality activated carbon.

[0049] Step 1: Heat 7.5 tons of rice husks to 550-580°C for smoldering and carbonization to obtain 2.5 tons of rice husk charcoal;

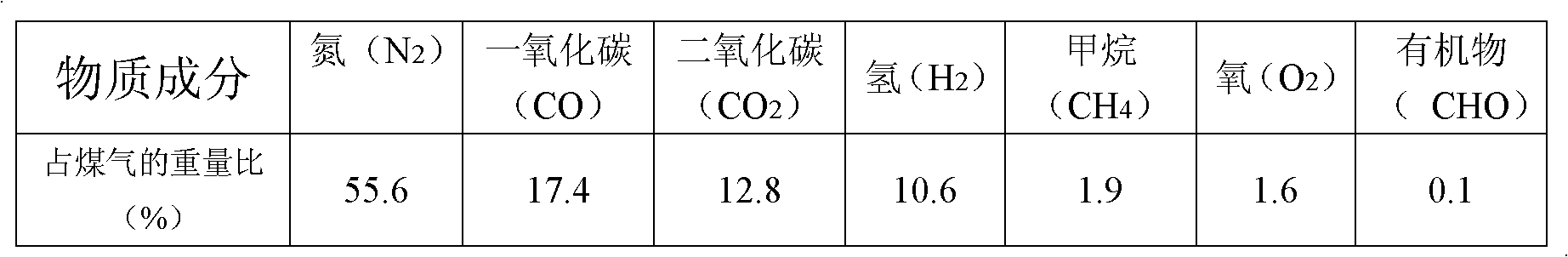

[0050] Step 2: Moisten 2.5 tons of the obtained rice husk charcoal with 2.6 tons of phosphoric acid solution with a concentration of 25%, add 200kg of dry rice husks and mix well, then, seal and seal with a paper bag (do not leak carbon powder) Put it in an activation furnace for activation, the activation temperature is 680-720°C, and the activation time is 20-30 minutes; after the activation is completed, the carbon material in the furnace is taken out of the furnace, soaked in clean water and then filtered. The filtrate is silicon phosphate, and the filter residue is dried. It is primary activated carbon, weighing about 3.2 tons (activated carbon particles contain a large amount of silicon phosphate);

[0051] The third step: Soak 3.2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com