Method for preparing titanium dioxide nano-rod array materials at low temperature

A nanorod array, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, metal material coating technology, etc., can solve the problems of use, complex process surfactant addition, etc., achieve less environmental pollution, easy monitoring and control, product cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

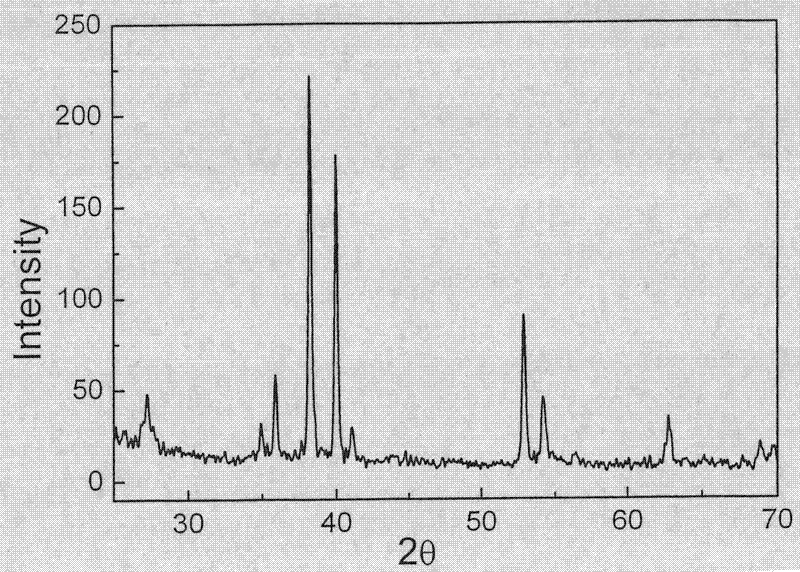

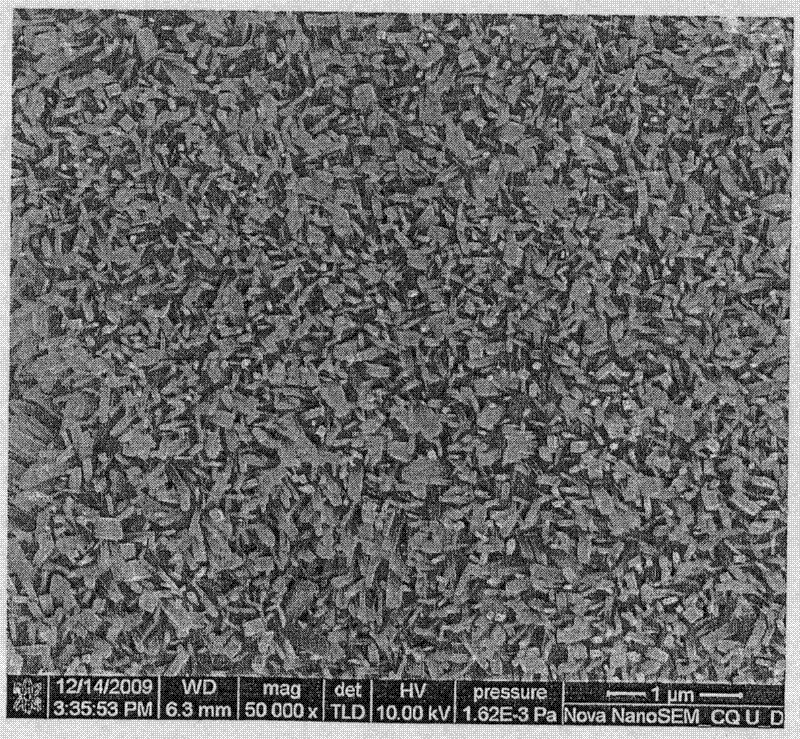

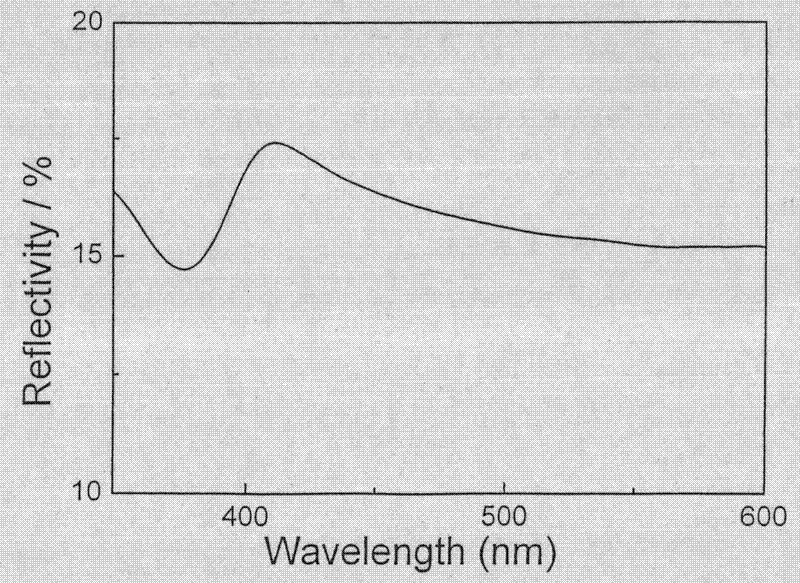

[0031] Specific synthesis method of low-temperature titania nanorod arrays

[0032] The raw material for synthesizing titanium dioxide nanorod array material is hydrochloric acid (HCl), the reaction that titanium substrate (Ti) takes place is as follows:

[0033] Ti+4HCl→TiCl 4 +2H 2 ,

[0034] TiCl 4 +3H 2 O→H 2 TiO 3 ↓+4HCl,

[0035]

[0036] The specific operation steps are as follows:

[0037] Step 1, cleaning of the titanium substrate, the titanium substrate is ultrasonicated for 10 minutes in a mixed solution of alcohol and acetone with a volume ratio of 1:1, and rinsed with deionized water;

[0038] Step 2, remove the oxide layer of the titanium substrate, put the titanium substrate in 7% hydrochloric acid solution, heat it at 95°C in a water bath heater for 10 minutes, rinse it with deionized water, and finally dry it for use;

[0039] Step 3, preparing a reaction solvent, dissolving hydrochloric acid in an appropriate amount of water, and controlling the c...

Embodiment 2

[0042] Specific synthesis method of low-temperature titania nanorod arrays

[0043] The raw material for synthesizing titanium dioxide nanorod array material is hydrochloric acid (HCl), the reaction that titanium substrate (Ti) takes place is as follows:

[0044] Ti+4HCl→TiCl 4 +2H 2 ,

[0045] TiCl 4 +3H 2 O→H 2 TiO 3 ↓+4HCl,

[0046]

[0047] The specific operation steps are as follows:

[0048] Step 1, cleaning of the titanium substrate, the titanium substrate is ultrasonicated for 10 minutes in a mixed solution of alcohol and acetone with a volume ratio of 1:1, and rinsed with deionized water;

[0049] Step 2, remove the oxide layer of the titanium substrate, put the titanium substrate into 18% hydrochloric acid solution, heat it at 65°C in a water bath heater for 10 minutes, rinse it with deionized water, and finally dry it for use;

[0050] Step 3, preparing a reaction solvent, dissolving hydrochloric acid in an appropriate amount of water, and controlling th...

Embodiment 3

[0053] Specific synthesis method of low-temperature titania nanorod arrays

[0054] The raw material for synthesizing titanium dioxide nanorod array material is hydrochloric acid (HCl), the reaction that titanium substrate (Ti) takes place is as follows:

[0055] Ti+4HCl→TiCl 4 +2H 2 ,

[0056] TiCl 4 +3H 2 O→H 2 TiO 3 ↓+4HCl,

[0057]

[0058] The specific operation steps are as follows:

[0059] Step 1, cleaning of the titanium substrate, the titanium substrate is ultrasonicated for 10 minutes in a mixed solution of alcohol and acetone with a volume ratio of 1:1, and rinsed with deionized water;

[0060] Step 2, remove the oxide layer of the titanium substrate, put the titanium substrate into 10% hydrochloric acid solution, heat it at 80°C in a water bath heater for 10 minutes, rinse it with deionized water, and finally dry it for use;

[0061] Step 3, preparing a reaction solvent, dissolving hydrochloric acid in an appropriate amount of water, and controlling the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com