Wetting agent and application thereof in binary compound flooding tertiary oil recovery

A wetting agent and ethylene glycol technology, applied in the field of oil production in oil fields, can solve the problems of not many and complex reservoir wettability, and achieve the effects of low production cost, improved oil recovery, and easy operation of process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: 23% of sulfoamide betaine, 17% of alkylamide hydroxysulfonamide betaine, 15.5% of sulfonic acid imidazoline, 1% of fatty alcohol polyoxyethylene ether, polyoxyethylene sorbitan monooleic acid 0.5% of fat, 0.7% of polyoxyethylene alkylamine, 0.3% of fatty acid methyl ester ethoxylate, 1.5% of ethylene glycol fat, 1.5% of glyceride, 39% of distilled water, heated at 70°C and stirred for 20 minutes, and obtained D.

Embodiment 2

[0013] Embodiment 2: 13% of sulfoamide betaine, 7% of alkylamide sulfonamide betaine, 6% of sulfonic acid imidazoline, 7% of fatty alcohol polyoxyethylene ether, polyoxyethylene sorbitan monooleic acid Fatty acid 3%, polyoxyethylene alkyl amine 1.7%, fatty acid methyl ester ethoxylate 1.3%, ethylene glycol fat 5.5%, glyceride 1.5%, distilled water 54%, heating temperature 70 ℃ and stirring time 20min and obtain D.

Embodiment 3

[0014] Embodiment 3: sulfoamide betaine 33%, alkylamide hydroxysulfonamide betaine 17% sulfonic acid type imidazoline 19%, fatty alcohol polyoxyethylene ether 0.5%, polyoxyethylene sorbitan monooleic acid 0.4% of fat, 0.3% of polyoxyethylene alkylamine, 0.3% of fatty acid methyl ester ethoxylate, 0.6% of ethylene glycol fat, 0.4% of glyceride, 28.5% of distilled water, heated at 70°C and stirred for 20 minutes, and obtained D.

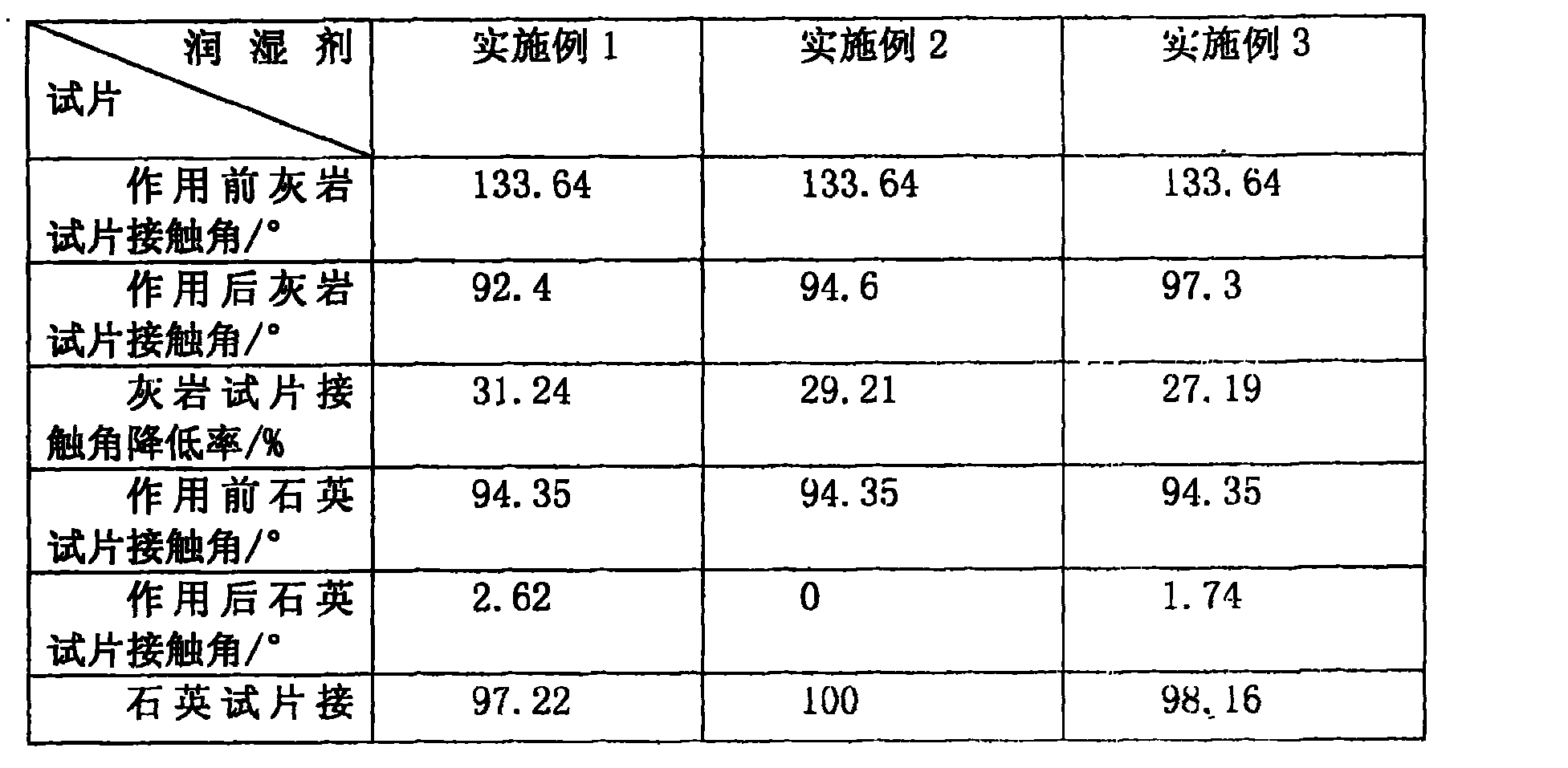

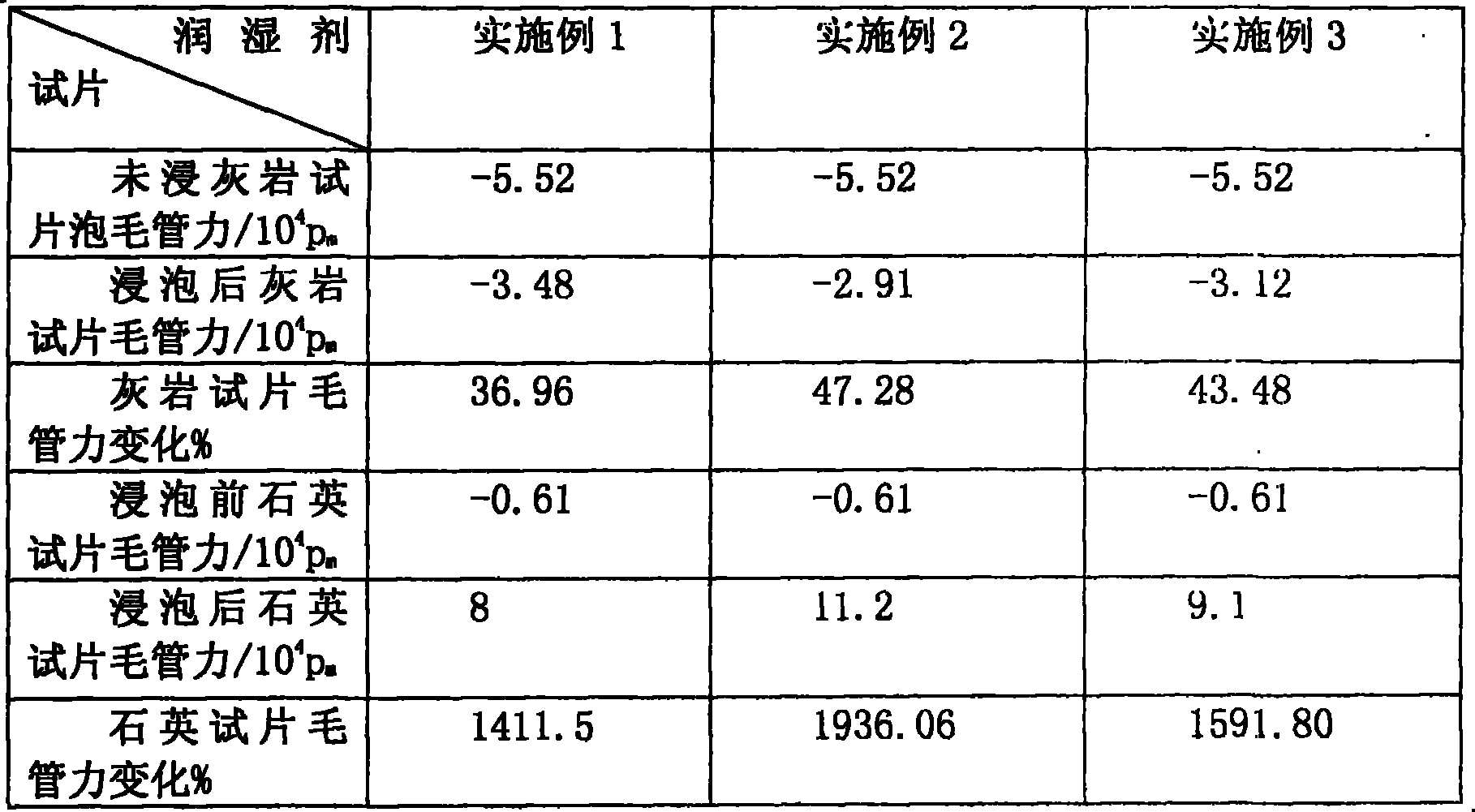

[0015] Quartz and limestone slices were cut into test pieces with a length of 3 cm, a width of 1.5 cm, and a thickness of 0.5 cm, and the test pieces were polished with metallographic sandpaper. Quartz is the main component of sandstone, which can represent sandstone, whose original wettability is moderately wet; limestone represents carbonate rock, whose original wettability is close to neutral.

[0016] Put the test piece into diluted crude oil and soak it at room temperature for two months. Take out the soaked test pieces and place them horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com