Hose coupler

A hose joint and a technology for connecting hoses, applied in the field of pipe joints, can solve the problems of connection strength, tightness, cumbersome and laborious loading and unloading operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

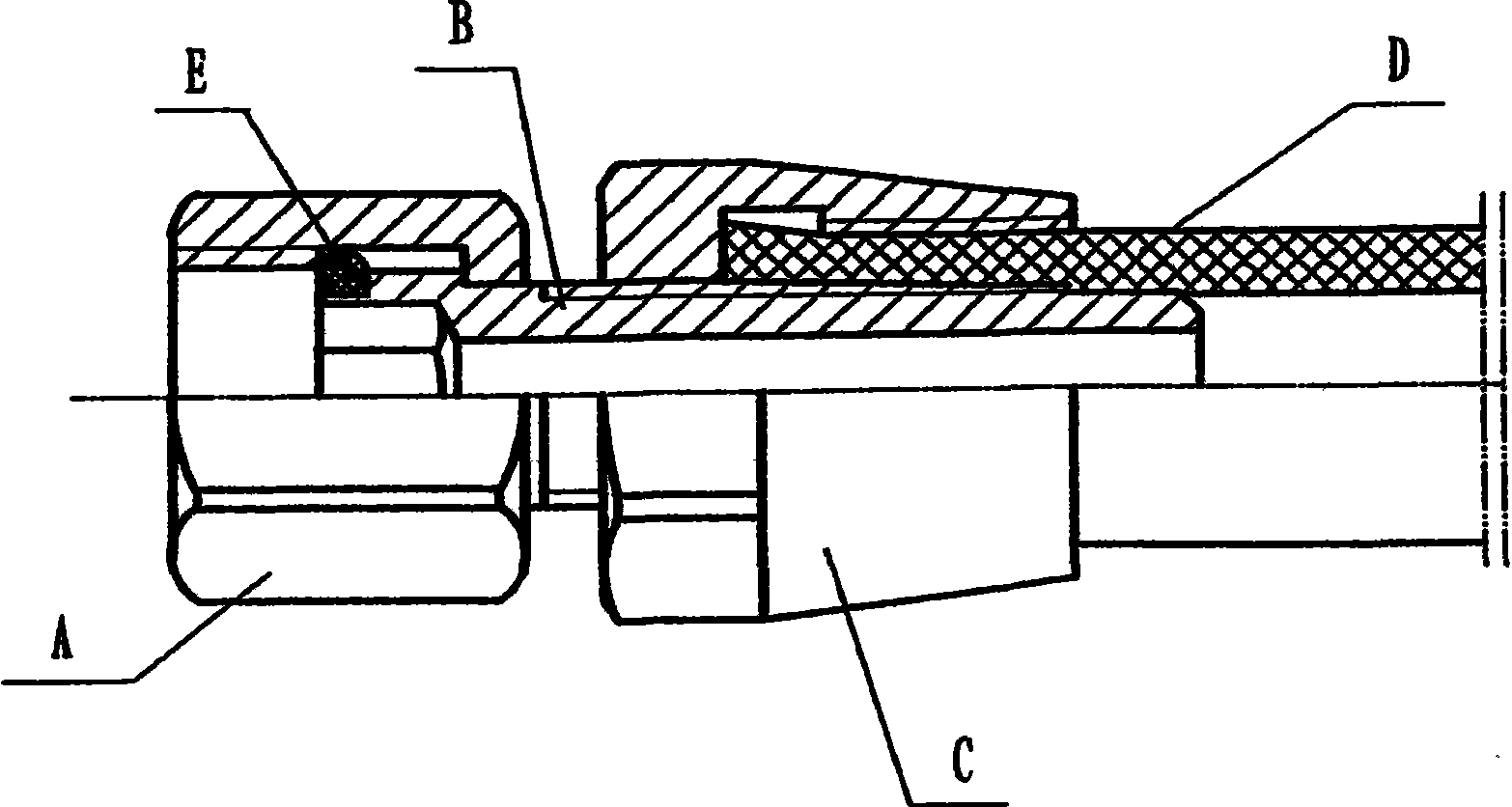

[0019] see Figure 1 to Figure 4 .

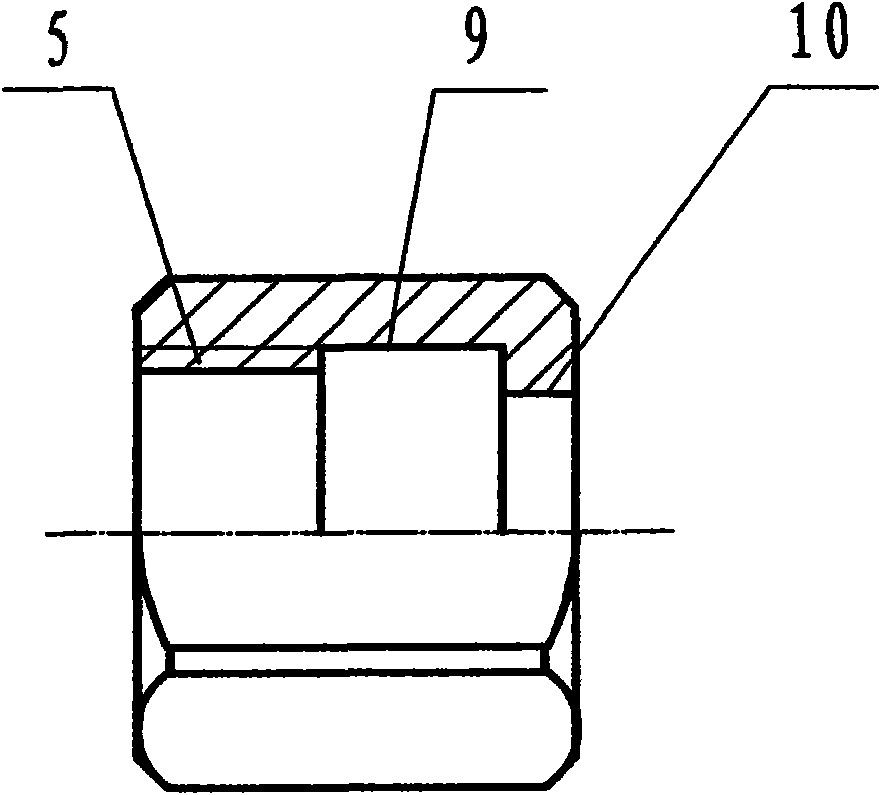

[0020] Depend on figure 1 It can be seen that the expansion collar joint is mainly composed of three parts: connecting live nut A, expansion tube bolt B and collar nut C.

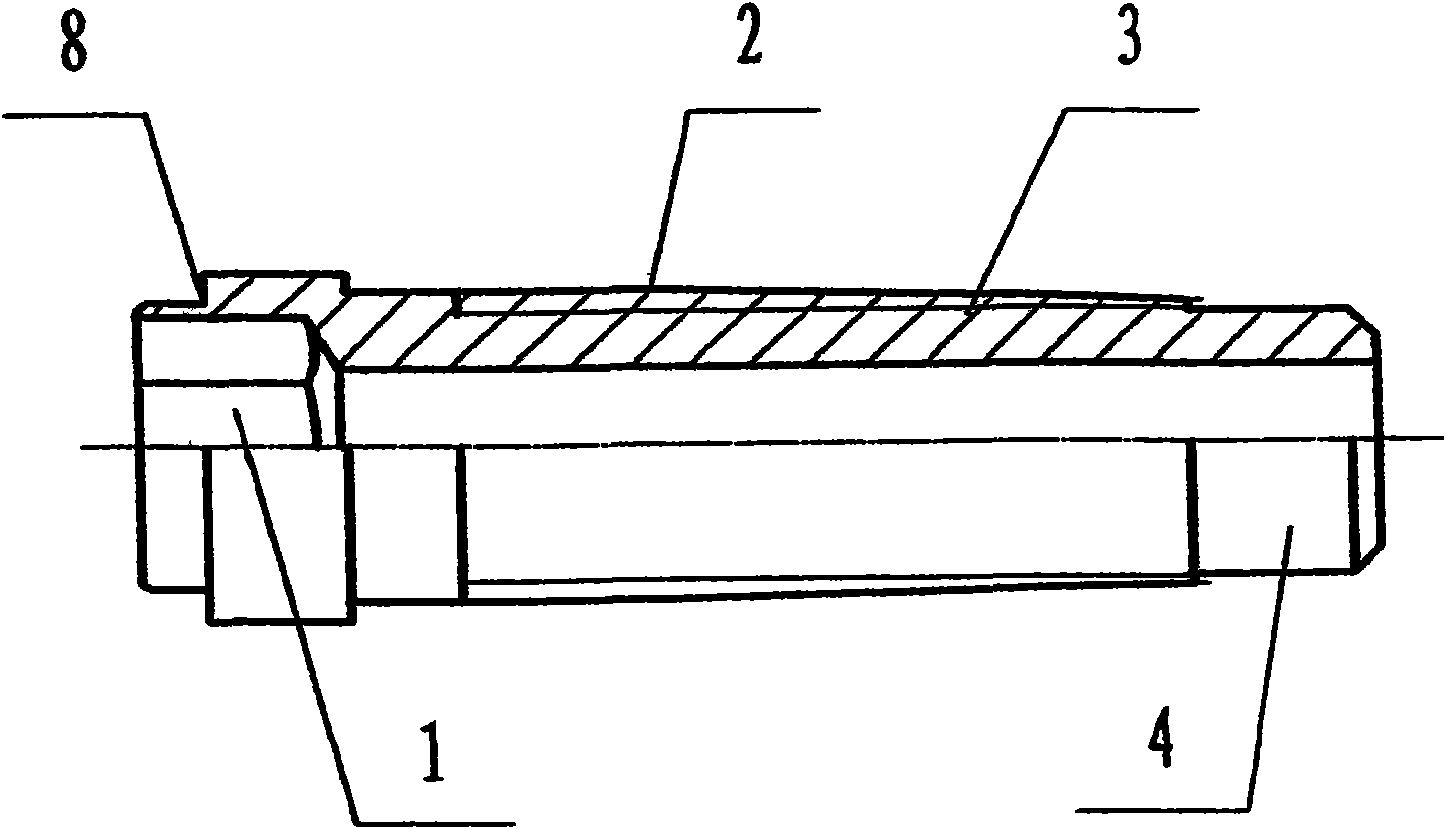

[0021] see figure 2 : Expansion tube bolt B, composed of hexagon socket hole 1, pipe connection external thread 2, expansion tube external thread 3, hose guide section 4, and stepped seam 8.

[0022] The inner hexagonal hole 1 should be selected from the standard inner hexagonal hole system. The selection principle is that the diameter of the inscribed circle of the inner hexagonal hole is slightly greater than or equal to the diameter of the through hole of the expansion tube core, so as to ensure that the joint has the largest through hole medium flow.

[0023] Pipe connection external thread 2 and expander pipe external thread 3 belong to the cylindrical section and conical section of the same thread surface; the thread outer diameter of pipe connection external t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com