Hardness test method

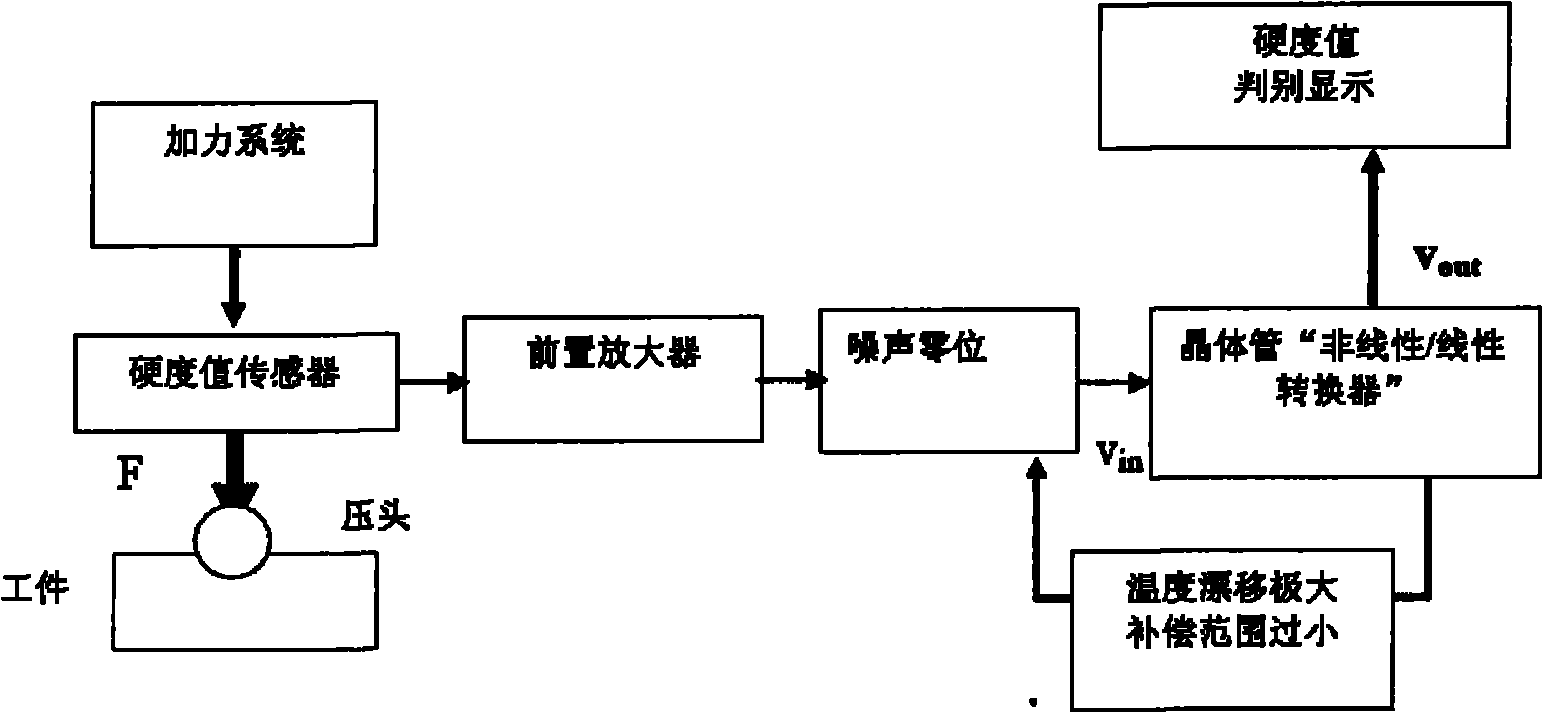

A detection method and hardness technology, applied in the direction of testing material hardness, etc., can solve the problems of serious temperature drift, small linear working range, unsatisfactory, etc., and achieve the effect of expanding the detection range and improving the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

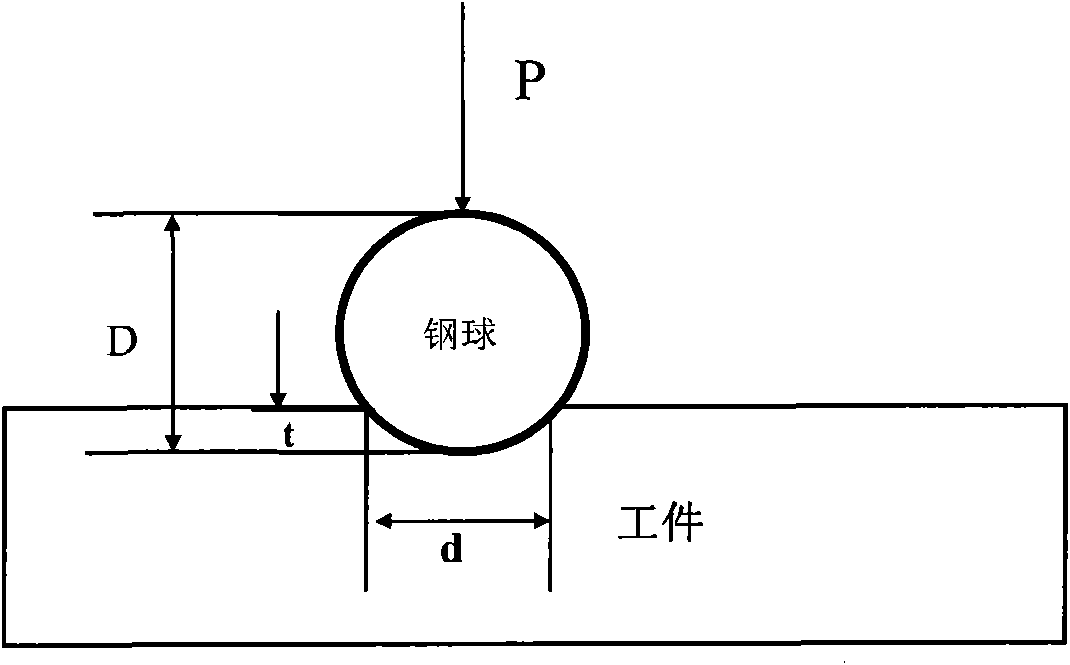

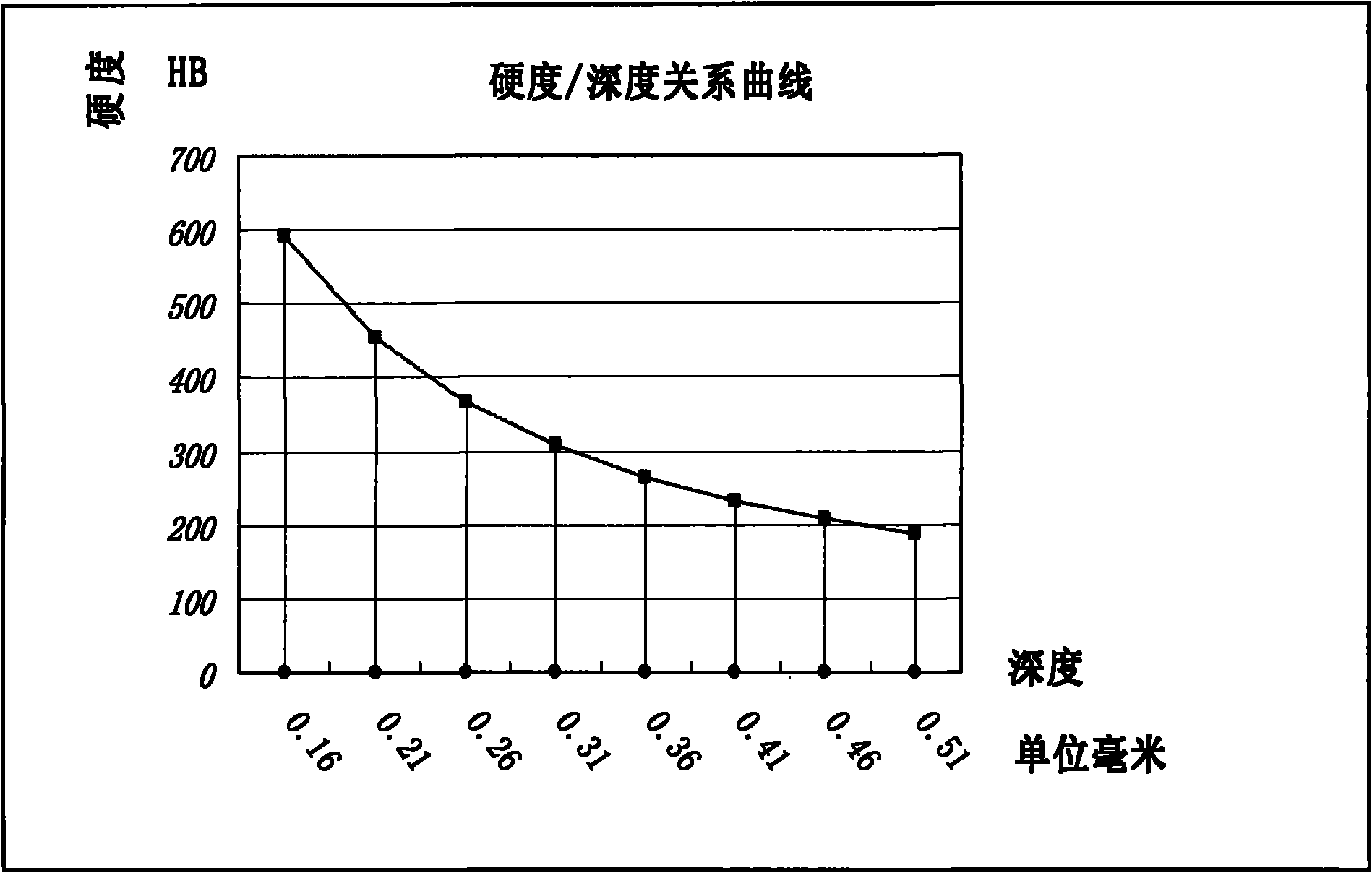

[0066] First, calibrate the working curve of the hardness tester (that is, the indentation depth-hardness value curve, HB=f(t)): After the force system generates a force of 3000 kg, it is applied to the probe of the hardness tester. Under the action of 3000 kg force, the corresponding indentation is produced on the tested test block. The depth of the indentation varies according to the hardness value. Generally, eight test blocks with different hardness values are used to form the working curve of the hardness tester. In this example, the hardness value of the hardness test block is HB592 to HB186, the working range of the hardness tester is 406HB, the corresponding indentation depth is 0.16mm-0.51mm, and the variation is 0.35mm. The corresponding parameters are listed in Table 1 below.

[0067] Table 1. Parameter relationship between the components of the hardness tester

[0068]

[0069]

[0070] These signals detected by the hardness probe can be amplified by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com