MEMS composite micro-energy system power supply

A system power and micro-energy technology, applied in hybrid batteries, circuits, electrical components, etc., can solve problems such as environmental hazards, composite system effects, and lack of recyclability, to improve work performance and stability, long service life, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

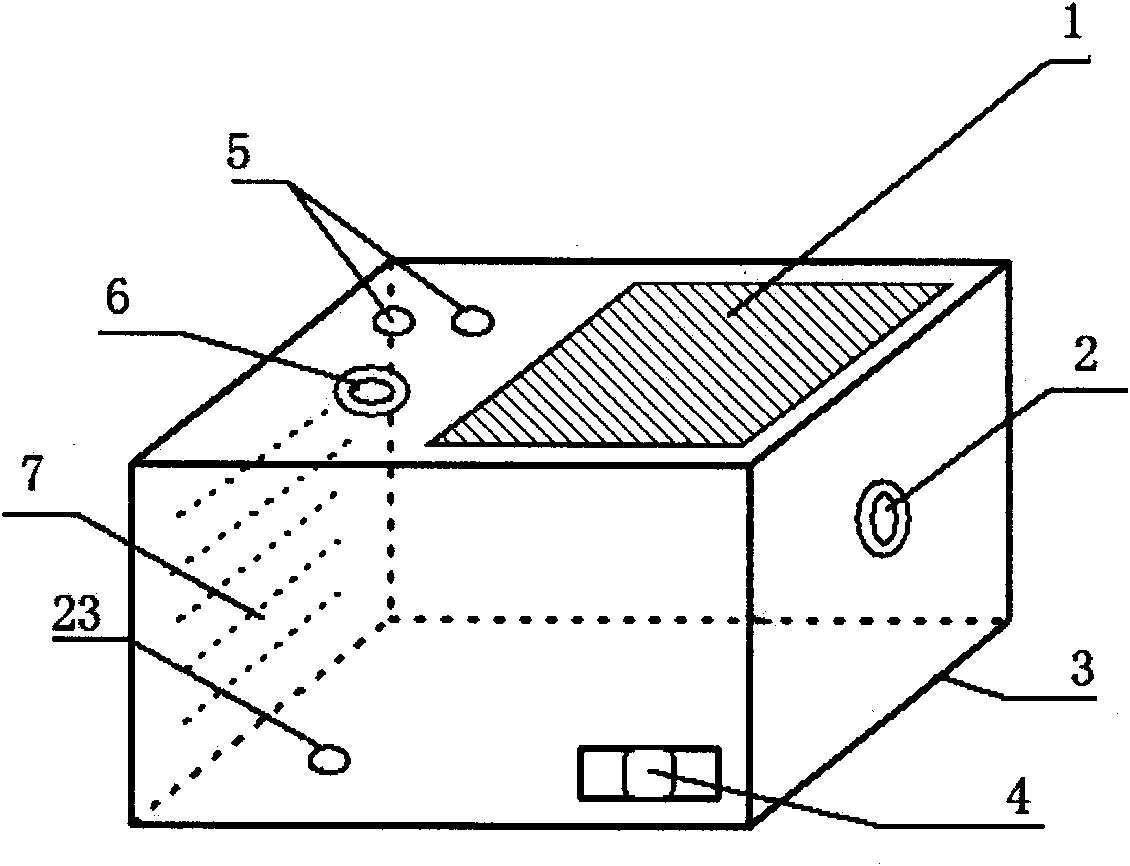

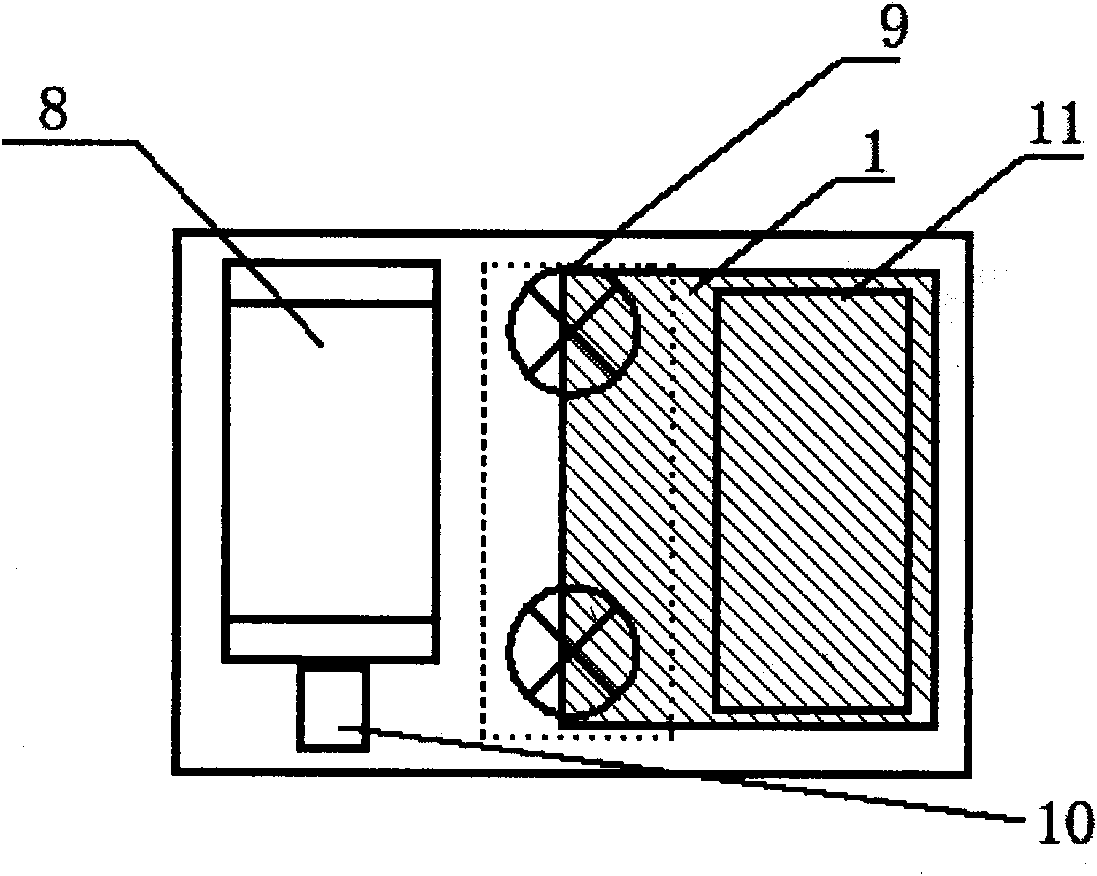

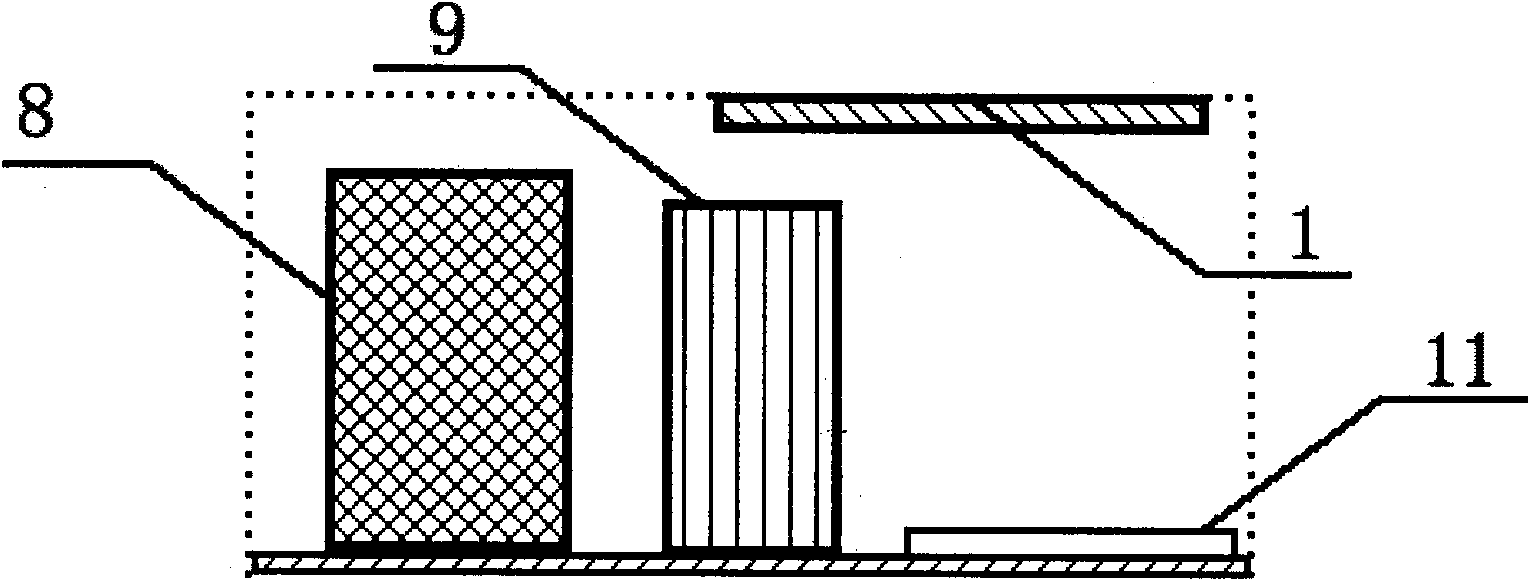

[0030] Further explanation according to the accompanying drawings:

[0031] Including MEMS miniature direct methanol fuel cell, MEMS miniature solar cell, MEMS miniature supercapacitor unit, ultra-low power consumption temperature sensor LM75B, 8-bit AVR series microprocessor ATmega168p, power management chip MAX1586B and shell, the shell is in the shape of a cuboid, MEMS micro The direct methanol fuel cell and MEMS micro-supercapacitor unit are installed inside the shell, the MEMS micro direct methanol fuel cell is installed near the right side wall of the shell, and the ultra-low power consumption temperature sensor LM75B is closely attached to the MEMS micro direct methanol fuel cell; the right side of the shell There are heat dissipation windows on the side wall, LED indicators for over-liquid / lack of liquid and a liquid injection port are provided on the top of the housing. The liquid injection port is connected to the MEMS micro direct methanol fuel cell. The front of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com