Plasma display panel

A plasma display and panel technology, applied in the direction of AC plasma display panels, gas discharge tubes/containers, electrical components, etc., can solve the problems of electron emission performance reduction, charge decay rate, charge retention performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

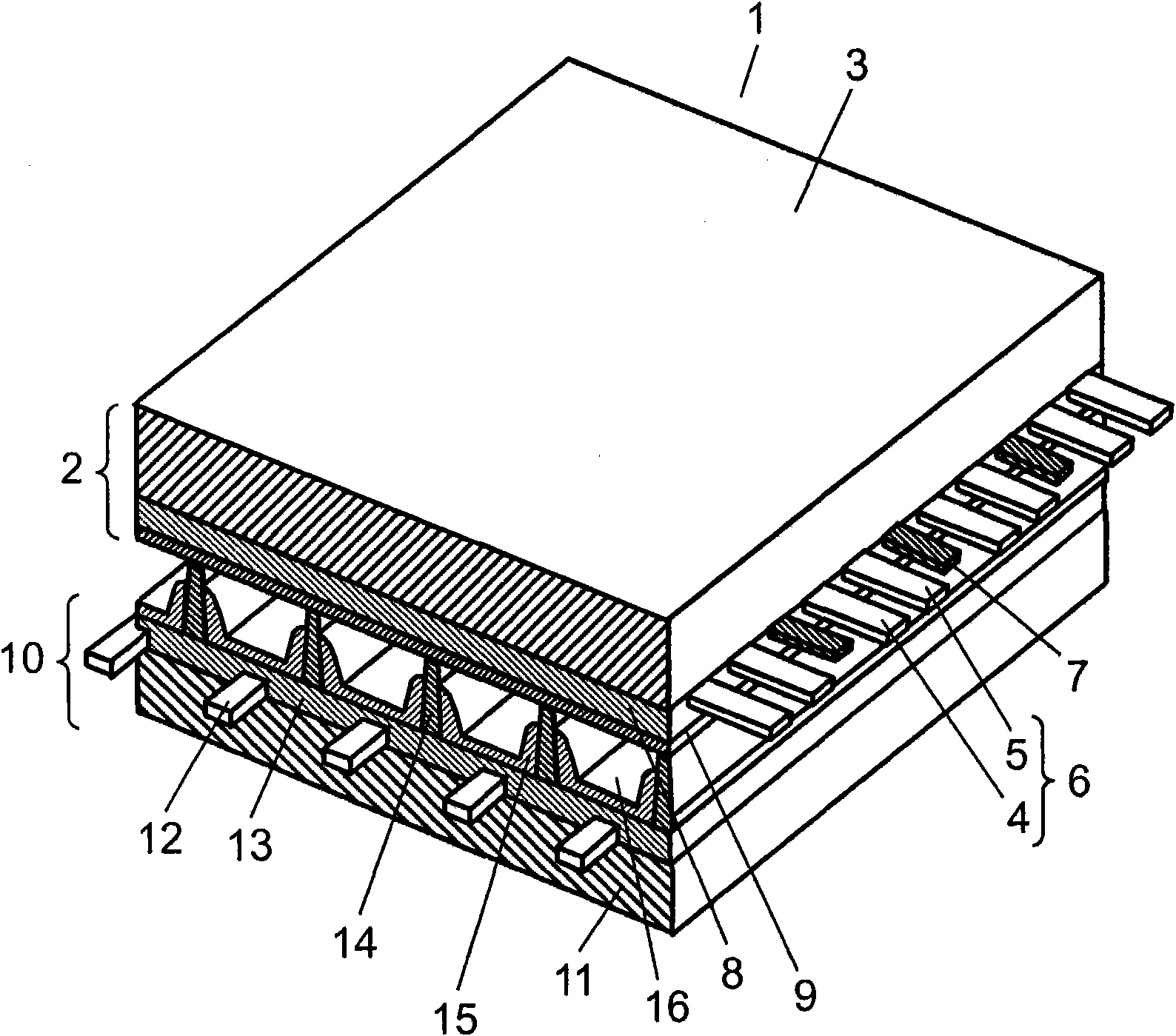

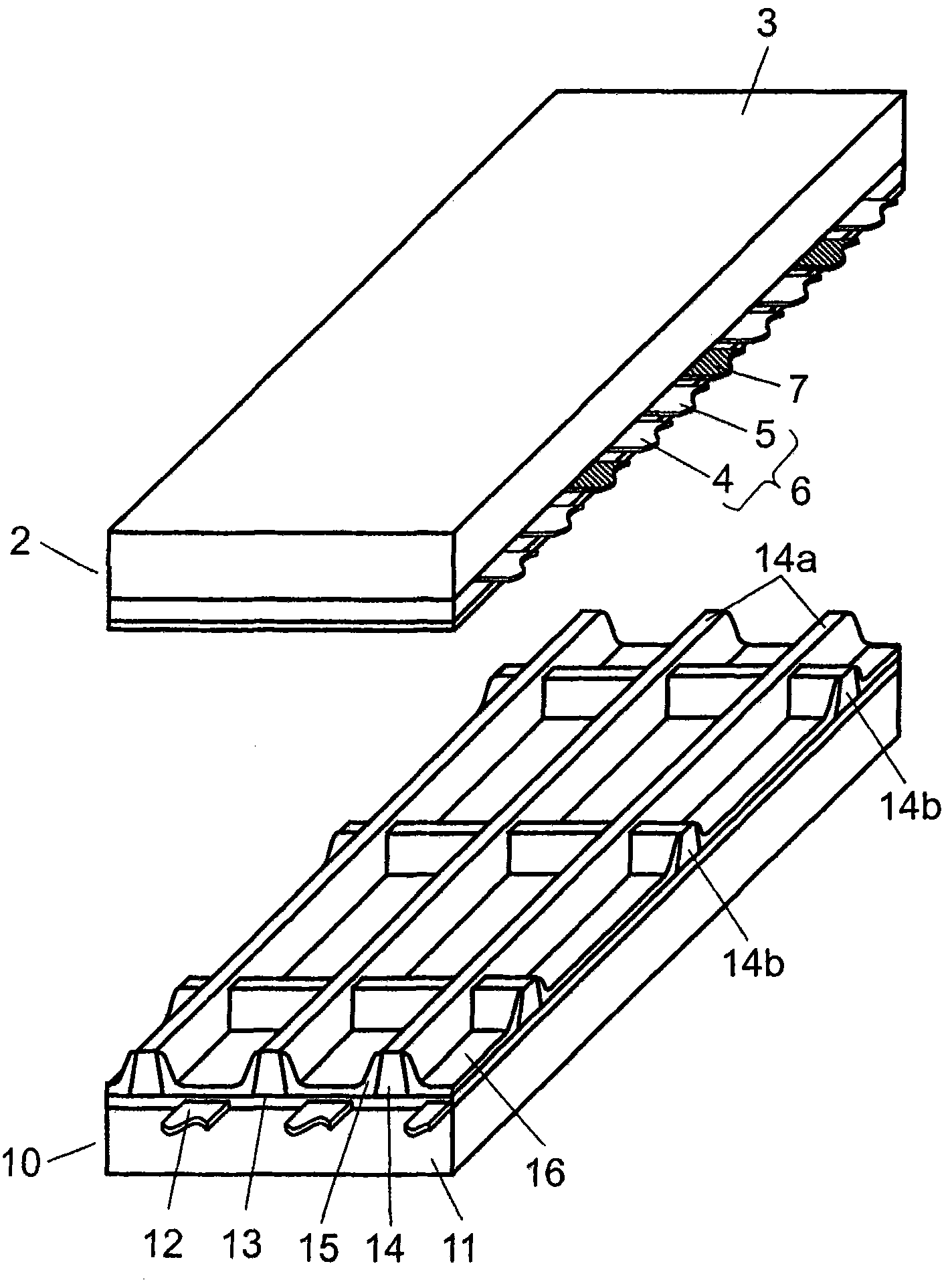

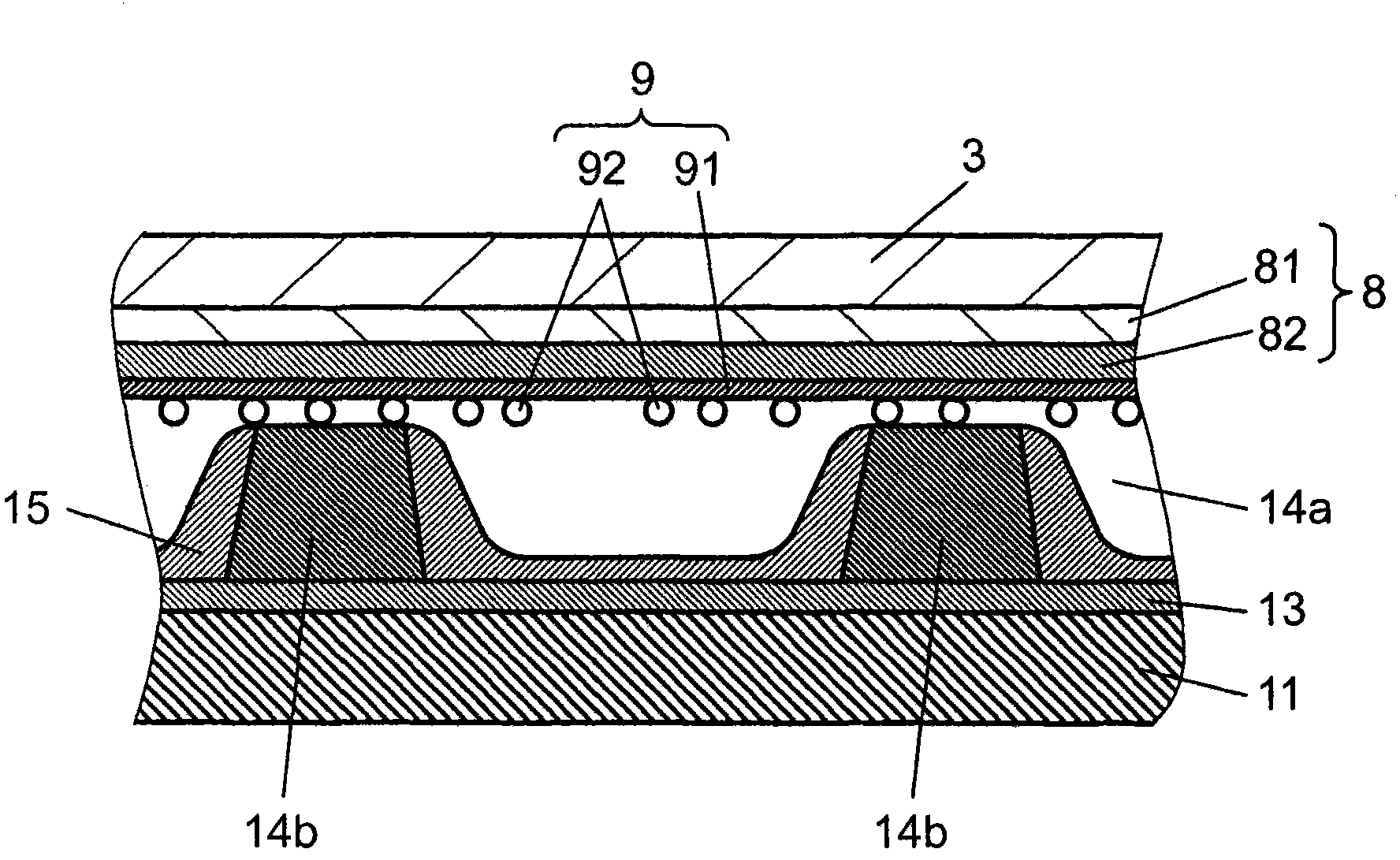

[0052] figure 1 It is a perspective view showing the structure of the PDP in the embodiment of the present invention. figure 2 It is a perspective view showing a front panel and a rear panel separately. image 3 is a cross-sectional view showing the cross-sectional structure of the discharge cell portion.

[0053] Such as figure 1 As shown, the PDP 1 is arranged such that a front panel 2 including a front glass substrate 3 and the like faces a rear panel 10 including a rear glass substrate 11 and the like. The outer peripheral portion of the PDP 1 is sealed with a sealing material made of glass frit or the like. Discharge gases such as Ne and Xe are sealed in the discharge space 16 inside the sealed PDP 1 at a pressure of 400 Torr to 600 Torr.

[0054] On the front glass substrate 3 of the front panel 2, a plurality of display electrodes 6 composed of a pair of strip-shaped scan electrodes 4 and sustain electrodes 5 and black stripes (light shielding layers) 7 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com