Accessory non-contact power supply type rotary ultrasonic machining device

A non-contact power supply, rotating ultrasonic technology, applied in the direction of circuit devices, electrical components, electromagnetic wave systems, etc., can solve the problems of machine tool spindle change, brush wear, unsuitable for machine tool transformation and upgrading, etc., to achieve convenient promotion, prevent heat and wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

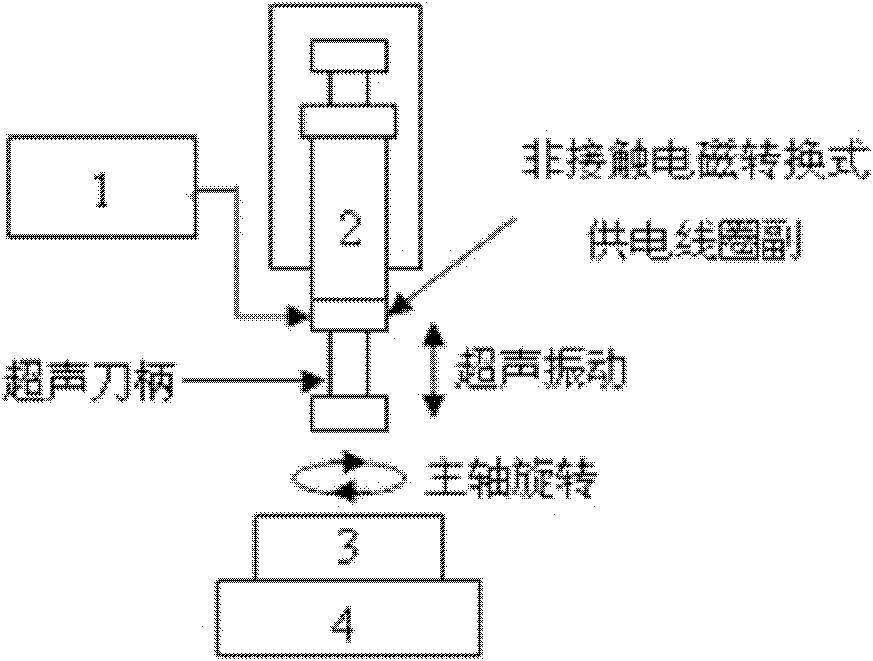

[0021] The invention consists of a set of accessory type non-contact power supply rotary ultrasonic processing device, including the following parts:

[0022] (1) Direct digital frequency synthesis ultrasonic generator with automatic frequency tracking function;

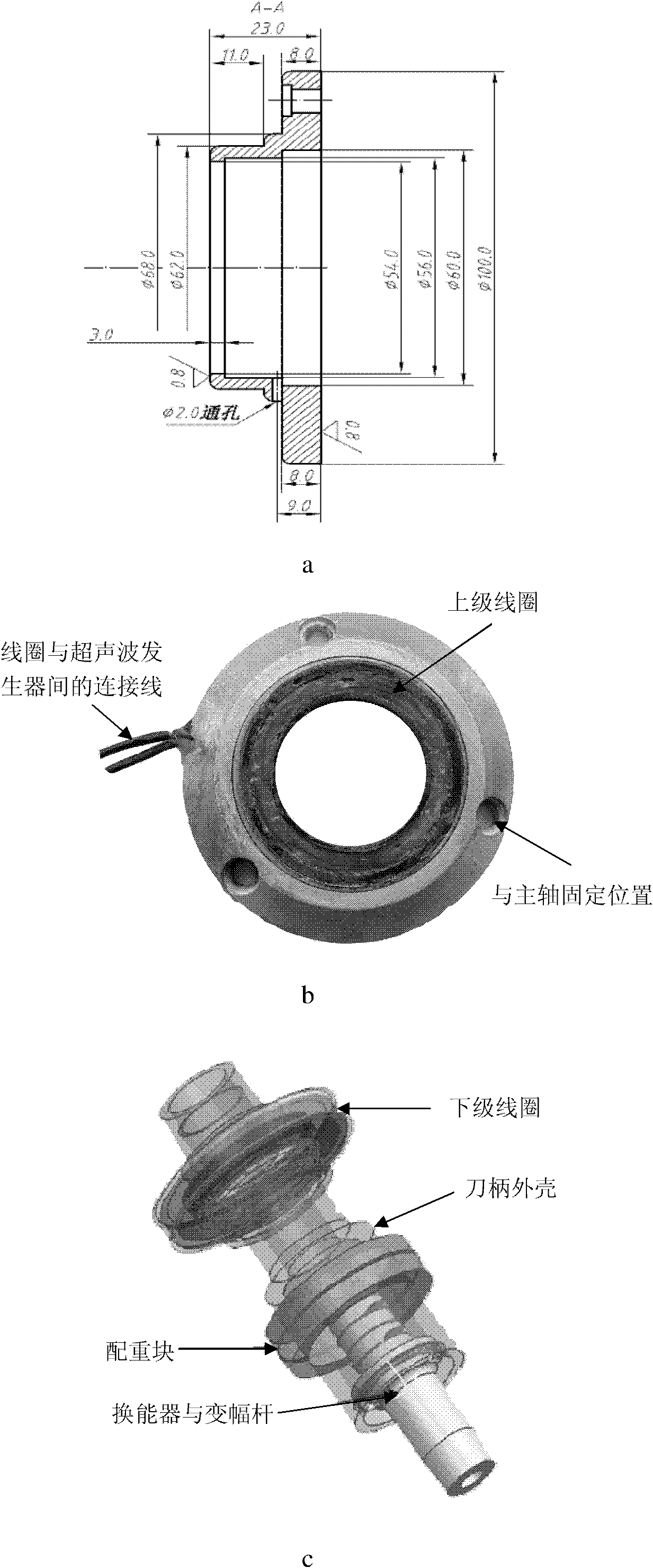

[0023] (2) Ultrasonic tool holder with standard spindle interface;

[0024] (3) On the basis of part (2), the ultrasonic vibration system is integrated inside the tool holder;

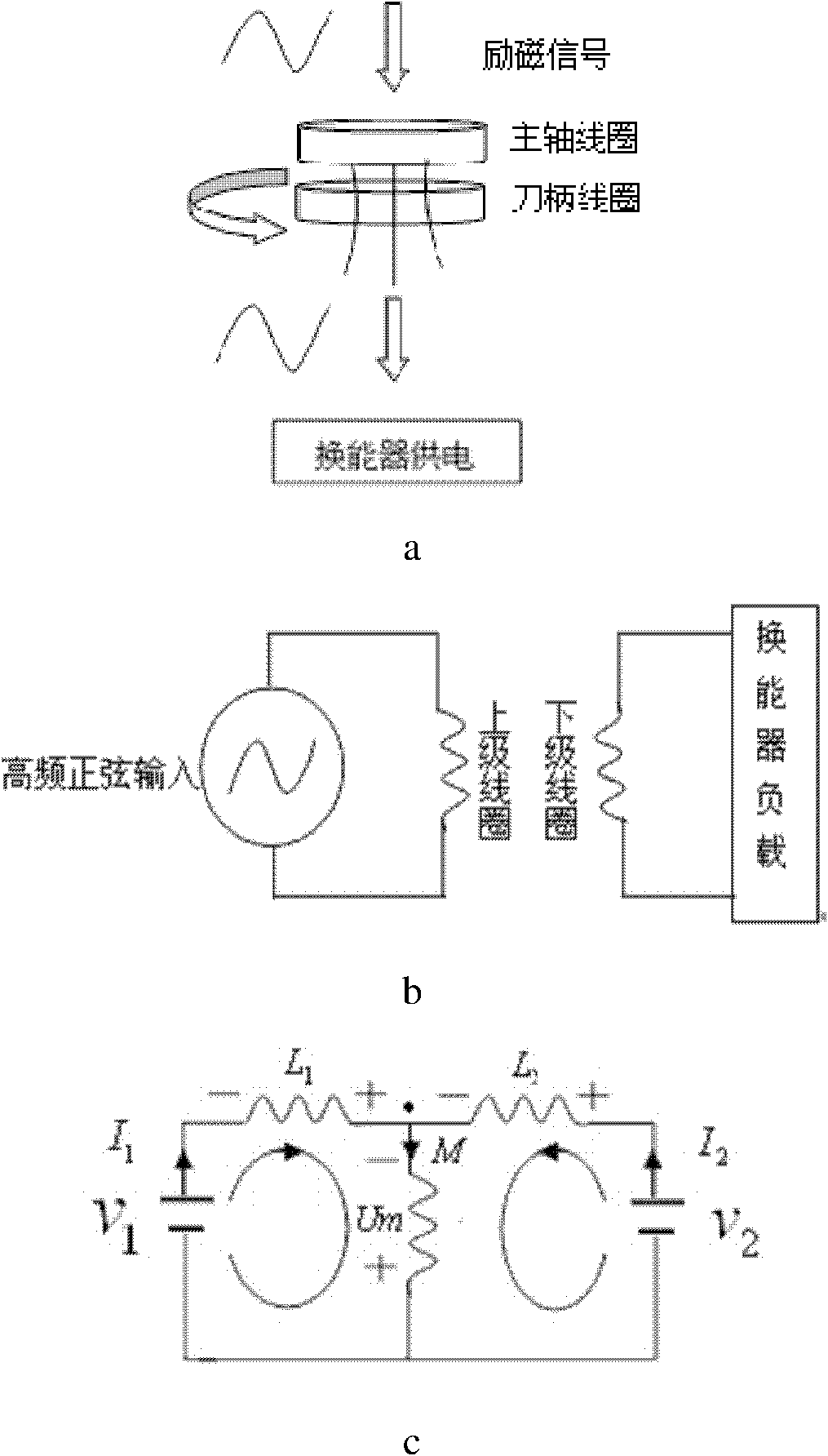

[0025] (4) Adopt non-contact electromagnetic conversion power supply method;

[0026] (5) Integrate the whole set of devices on the ordinary machine tool, that is, a complete set of accessory type non-contact power supply rotary ultrasonic processing device.

[0027] In the accessory-type non-contact power supply rotary ultrasonic machining device mentioned above, all functional components including the ultrasonic generator and ultrasonic vibration system are designed in the form of machine tool accessories.

[0028] Part (2) the tool hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com