Method for preparing metal magnesium and boron-enriched material from ascharite serving as raw material by vacuum thermal reduction method

A technology of magnesite and metal magnesium, which is applied in the field of low-silicon high-magnesium magnesia to produce metal magnesium and boron-rich materials by vacuum thermal reduction method, which can solve the problems of ecological environment damage, high cost and high price of alkali-free glass fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

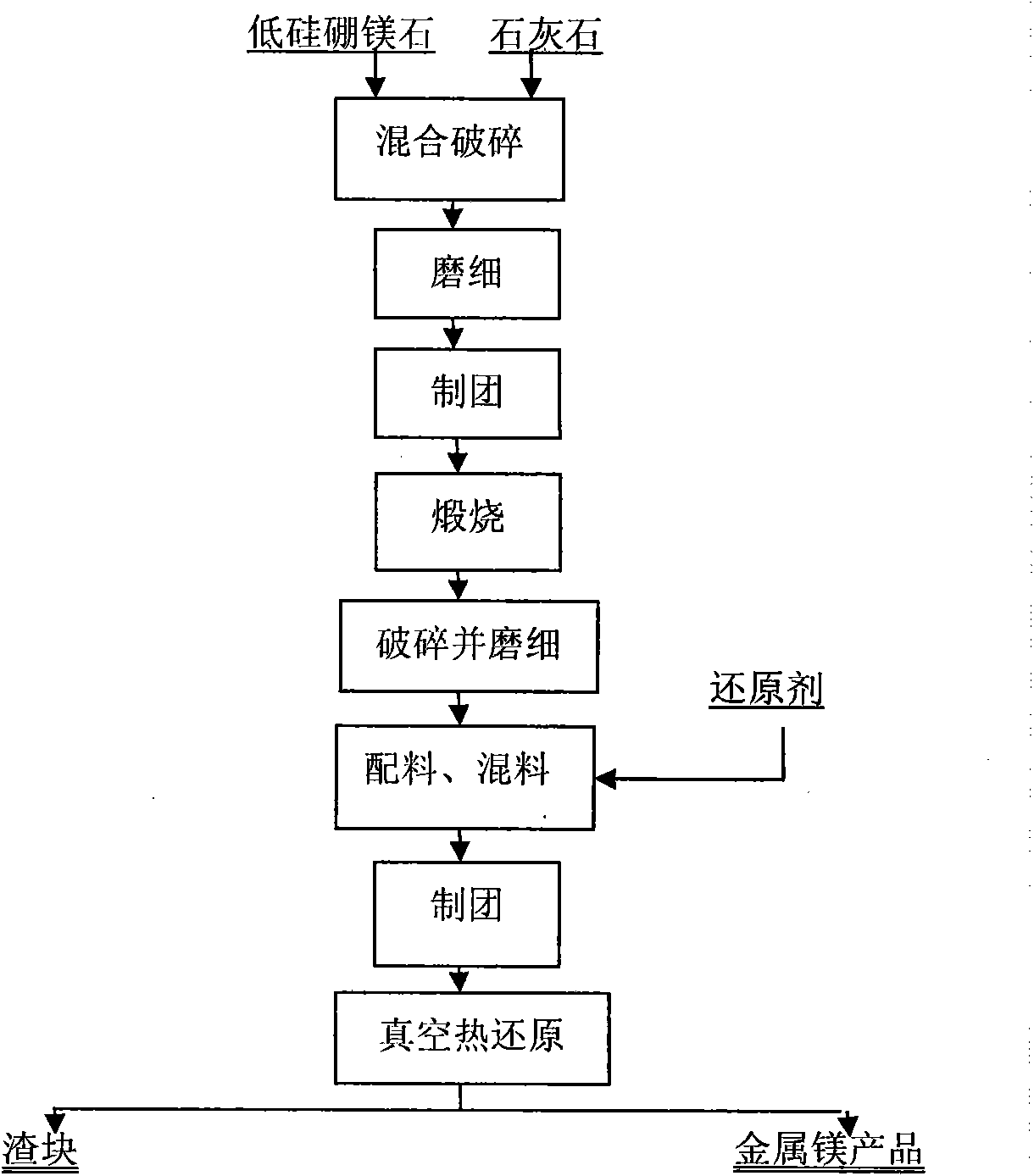

[0032] Magnesium metal is produced by vacuum aluminothermic reduction using natural low-silicon boronite and limestone as raw materials and aluminum powder less than 0.2 mm in size as reducing agent.

[0033] Analyze the composition of boromagnesite, and according to the content of MgO, B in boromagnesite 2 o 3 , SiO 2 、Al 2 o 3 The chemical composition of CaO and CaO is mixed into limestone, so that the CaO added can meet the demand of CaO in chemical reaction equations (1), (2), and (3). That is to make enough CaO and B 2 o 3 3CaO·B 2 o 3 , and SiO 2 Formation of 2CaO·SiO 2 , and the reduction reaction with Al 2 o 3 Formation of 12CaO·7Al 2 o 3 Demand for CaO.

[0034] After the above two raw materials are prepared according to the above ratio, they are mixed and crushed and put into an abrasive device for grinding, or the above two raw materials can be crushed and ground separately and then mixed evenly. Then the finely ground raw materials are made into aggl...

Embodiment 2

[0041] Vacuum heat reduction is carried out by using boronite and limestone after flotation desiliconization as raw materials and aluminum powder with a particle size less than 0.2mm as reducing agent. There is a large amount of high-silicon and high-magnesium boronite in Liaoning, China. After the silicon content of this ore is reduced by flotation, metal magnesium can also be extracted directly through vacuum thermal reduction, and at the same time, boron-rich materials and aluminum hydroxide or alumina are by-products.

[0042] Analyze the composition of boromagnesite, and according to the content of MgO, B in boromagnesite 2 o 3 , SiO 2 、Al 2 o 3 The chemical composition of CaO and CaO is mixed into limestone, so that the CaO added can meet the demand of CaO in chemical reaction equations (1), (2), and (3). That is to make enough CaO and B 2 o 3 3CaO·B 2 o 3 , and SiO 2 Formation of 2CaO·SiO 2 , and the reduction reaction with Al 2 o 3 Formation of 12CaO·7Al 2...

Embodiment 3

[0050] Vacuum thermal reduction is carried out with low-silicon boronite and limestone as raw materials and aluminum-magnesium alloy powder with a particle size of less than 0.2 mm as reducing agent.

[0051] Analyze the composition of boromagnesite, and according to the content of MgO, B in boromagnesite 2 o 3 , SiO 2 、Al 2 o 3 The chemical composition of CaO and CaO is mixed into limestone, so that the CaO added can meet the demand of CaO in chemical reaction equations (1), (2), and (3). That is to make enough CaO and B 2 o 3 3CaO·B 2 o 3 , and SiO 2 Formation of 2CaO·SiO 2 , and the reduction reaction with Al 2 o 3 Formation of 12CaO·7Al 2 o 3 Demand for CaO.

[0052] After the above two raw materials are prepared according to the above ratio, they are mixed and crushed and put into an abrasive device for grinding, or the above two raw materials can be crushed and ground separately and then mixed evenly. Then the finely ground raw materials are made into aggl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com