Road finisher and method

A technology of road paver and internal combustion engine, which is applied in the direction of roads, roads, road repair, etc., can solve the problems of high fuel consumption, pollute the environment, low efficiency, etc., and achieve the effect of high transportation speed and easy starting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

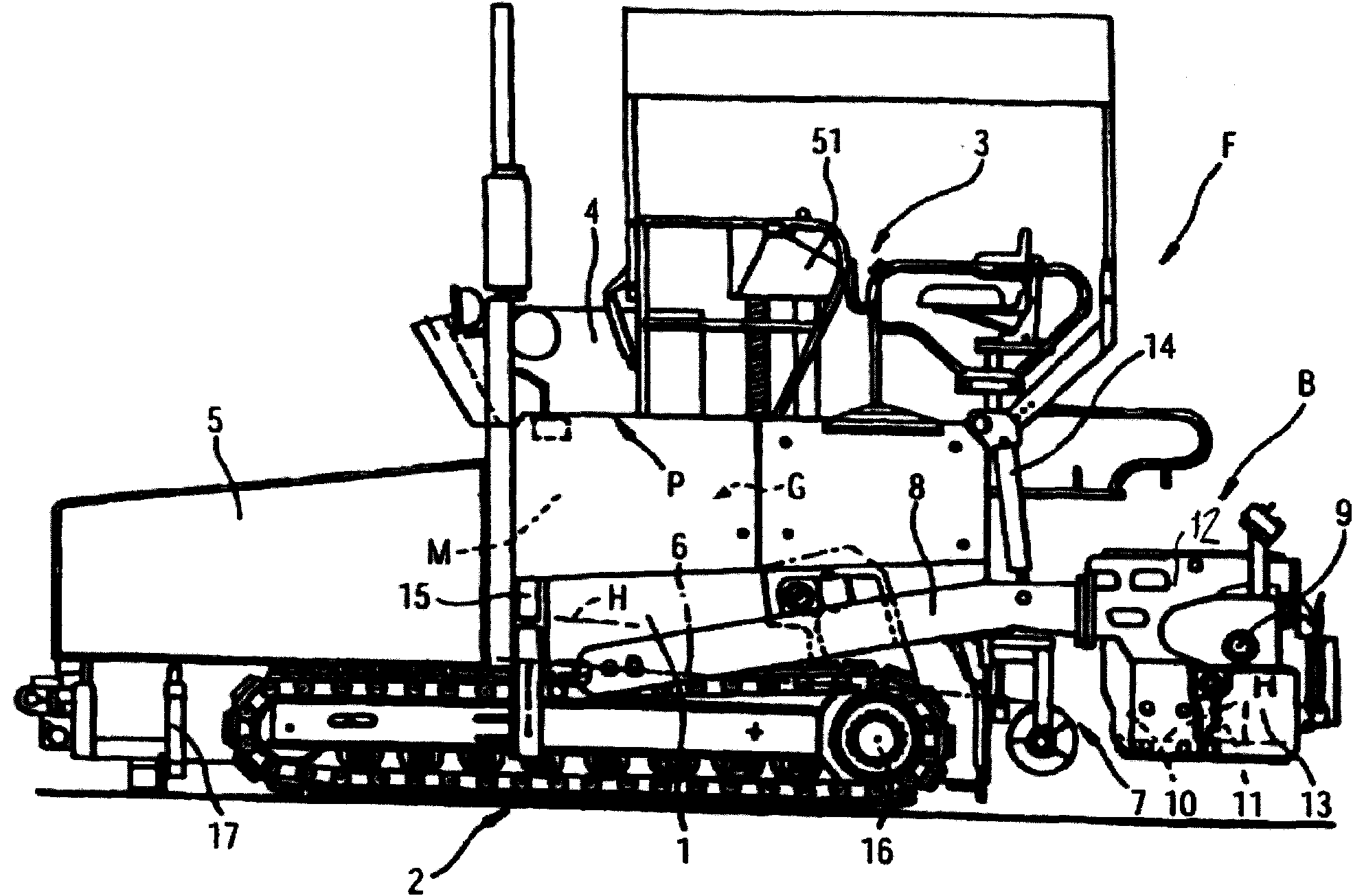

[0023] Self-propelled paving machine F ( figure 1 ) can also travel at significantly higher transport travel speeds. The paving machine F has a traveling frame 2 on a chassis 1 . The frame 2 shown is a tracked frame. Alternatively a wheeled carriage (not shown) may be provided. The traveling frame 2 is driven by at least one hydraulic drive motor 16 . A hopper 5 for paving material is arranged in the front area of the chassis 1 . The longitudinal conveying means 6 extend within and through the chassis 1 to a transverse distribution assembly 17 arranged at the rear end of the chassis 1 . The lateral distribution assembly 17 is typically a hydraulically driven lateral distribution auger. The longitudinal conveying device 6 can be driven, for example, by a hydraulic motor not shown, and can even include an electric heating device H. The transverse distribution assembly 17 is arranged in front of the paving screed B which is drawn by the paving machine F on the drawbar 8 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com