Micro-gas generator with closed cavity

A closed cavity and generator technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of complex structure, unsuitable for miniaturization, unsuitable for renewable energy, etc., and achieve the effect of low cost and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

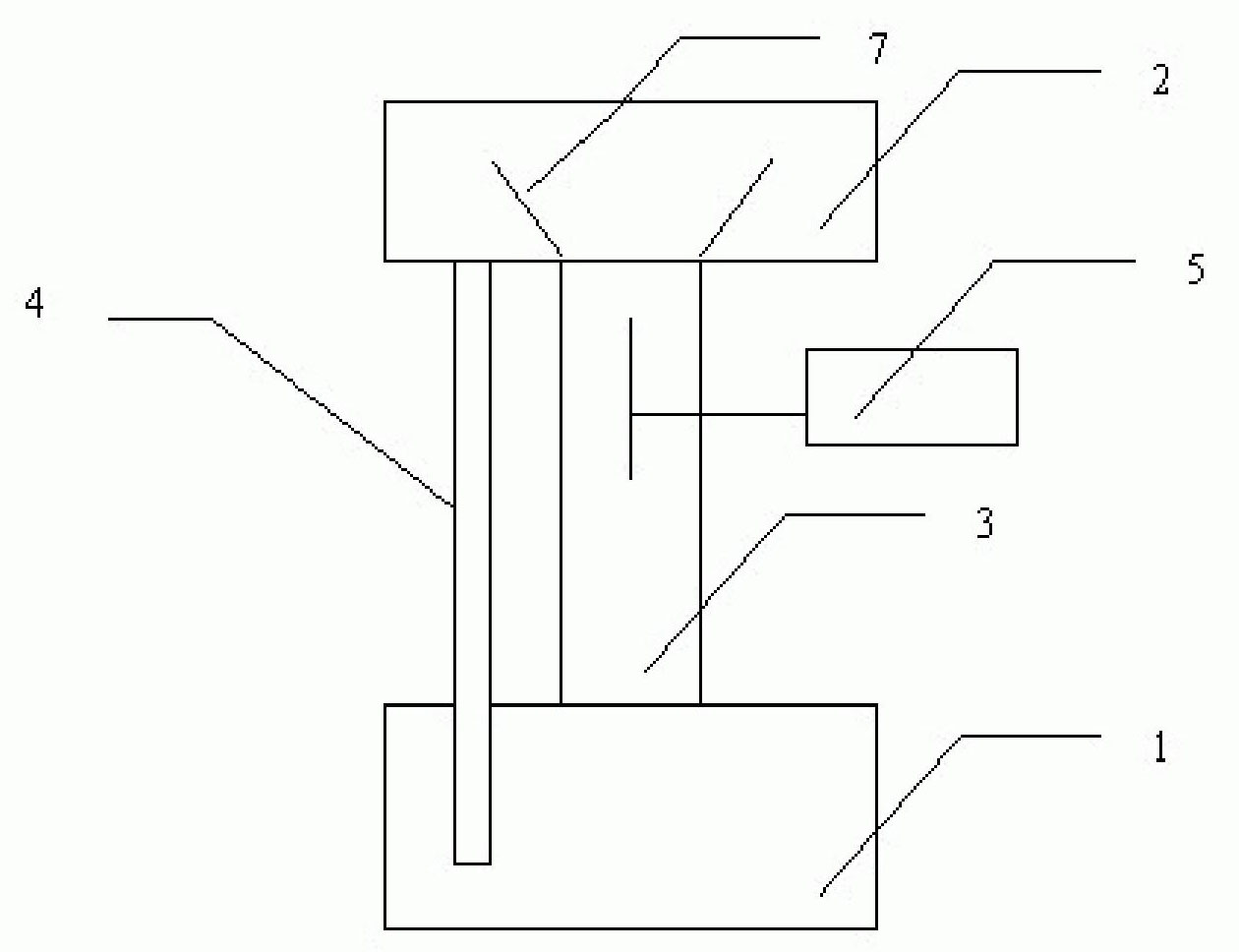

[0038] Embodiment 1, Natural Gas Closed Cavity Miniature Gas Generator

[0039] figure 1 The middle evaporation chamber 1 is heated by the external natural gas to evaporate the internal working medium 10. The evaporated gas enters the impeller area through a narrow channel, and after being sprayed, the impeller is driven to rotate. The exhausted steam enters the condensation chamber 2 and passes through the condensation chamber 2. After condensation, it enters the liquid return pipeline 4, and then goes to the evaporation chamber 1 through the liquid return pipeline 4 to realize cycle power generation.

Embodiment 2

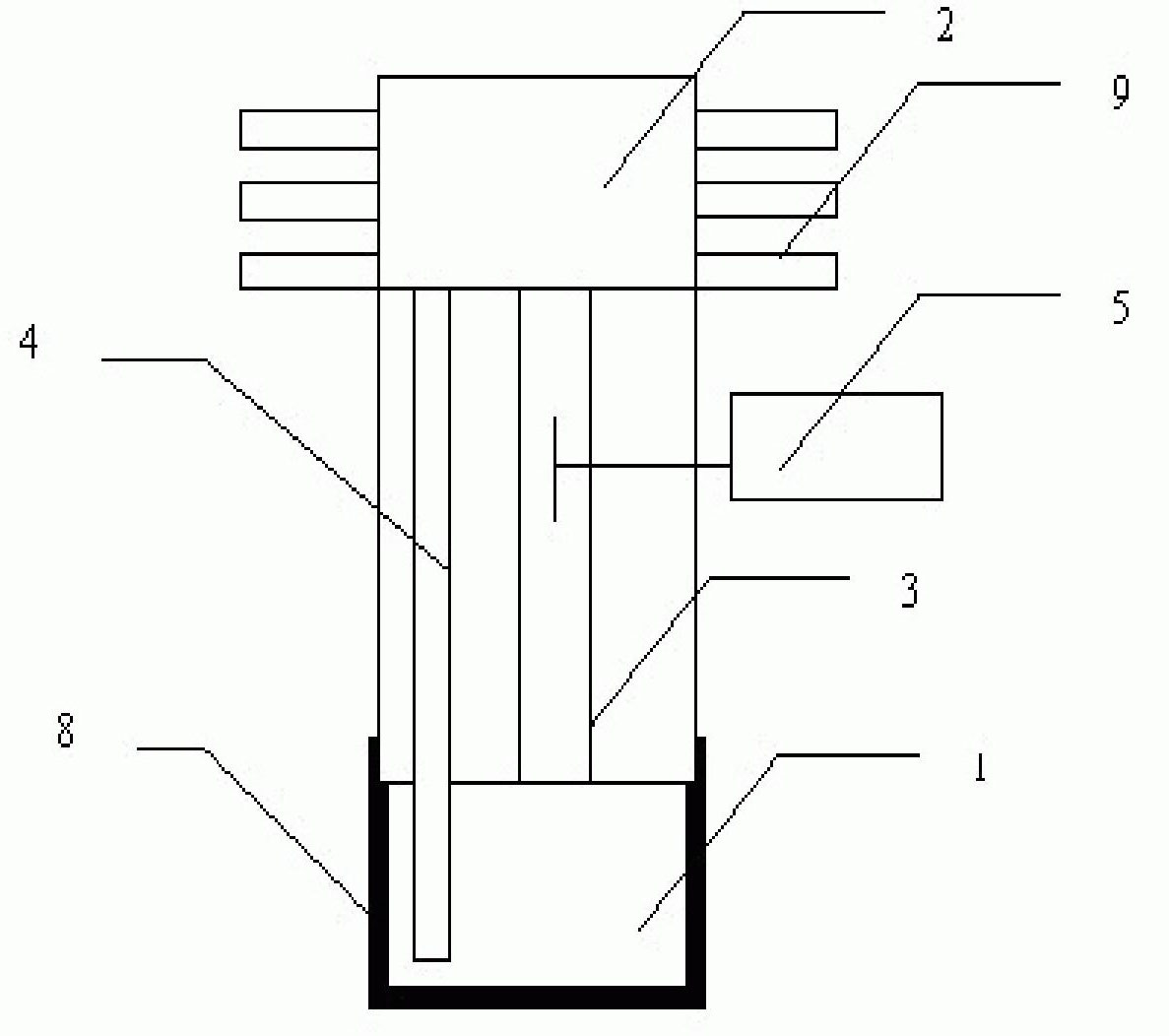

[0040] Embodiment 2, solar energy closed cavity micro-gas generator with fins

[0041] Put the selective coating 8 on the outside of the evaporation chamber 1, and generate heat energy under the irradiation of solar energy. The heat energy heats the internal working medium 10. After the working medium is vaporized, it drives the impeller through the narrow channel 3, and the rotation of the impeller drives the rotor to rotate to generate electricity. Fins 9 are arranged outside the chamber 2 to increase its condensation efficiency. After the working medium is condensed, the liquid is transported to the evaporation chamber 1 through the liquid return pipe 4 to realize cycle power generation.

Embodiment 3

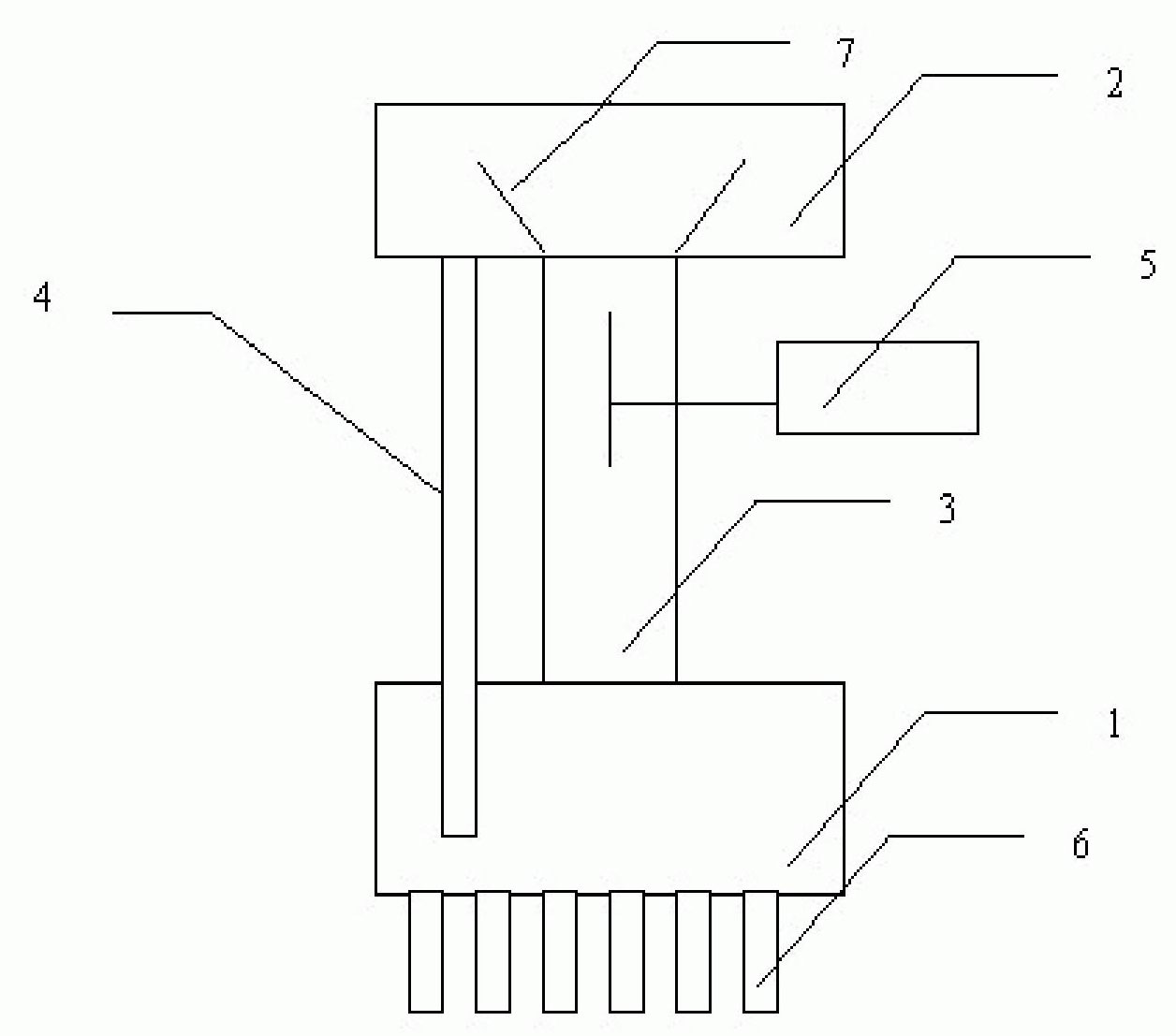

[0042] Embodiment 3, the closed cavity micro-gas generator with heat pipe

[0043] In this embodiment, the condensing section in the evaporation chamber is directly arranged in the liquid or gas area 11, and the heat is provided with a heat pipe through the heat exchange of the liquid in the condenser 3, and the heat pipe can be directly connected with various waste heat and with The temperature of the gas is exchanged, and the heat energy directly heats the liquid in the evaporation chamber, and after the vaporization is realized, the steam turbine is driven to generate electricity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com