Short-stroke pressure-maintaining high-pressure heavy hydraulic cylinder with high-pressure proximity switches

A technology of proximity switch and hydraulic cylinder, applied in the direction of fluid pressure actuating device, etc., can solve the problems of difficult operation limit precise control, inability to meet automatic control, poor repeat positioning accuracy, etc., to achieve convenient design and installation and debugging, improve system Safety, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

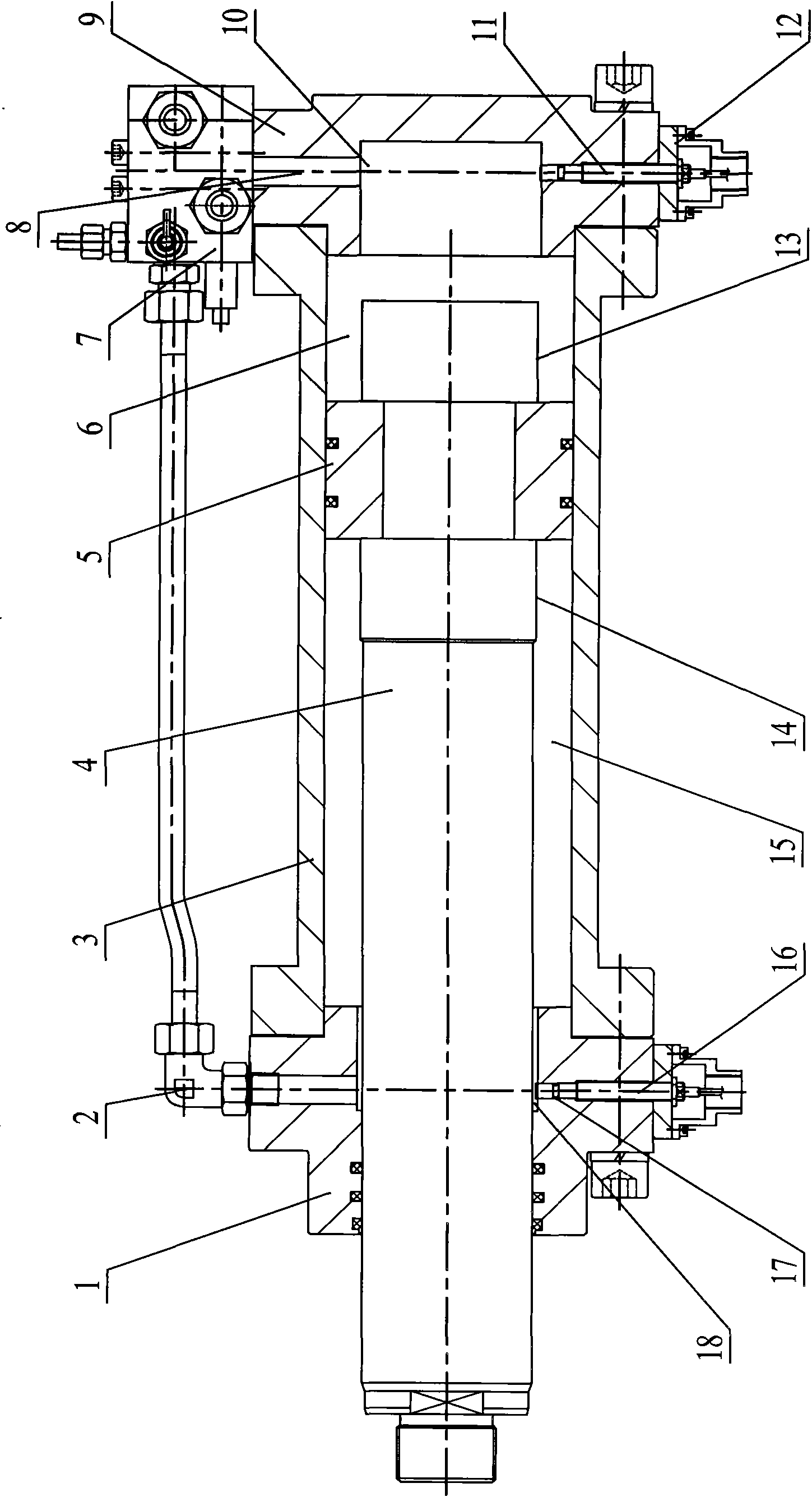

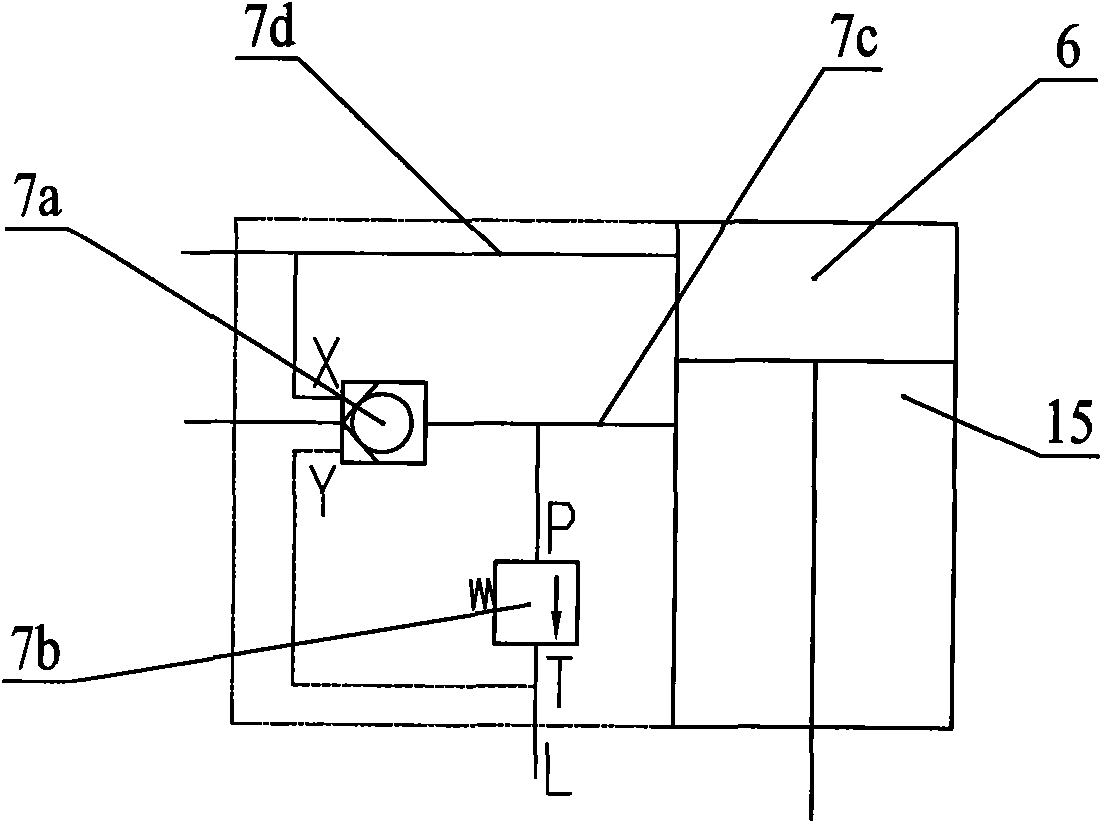

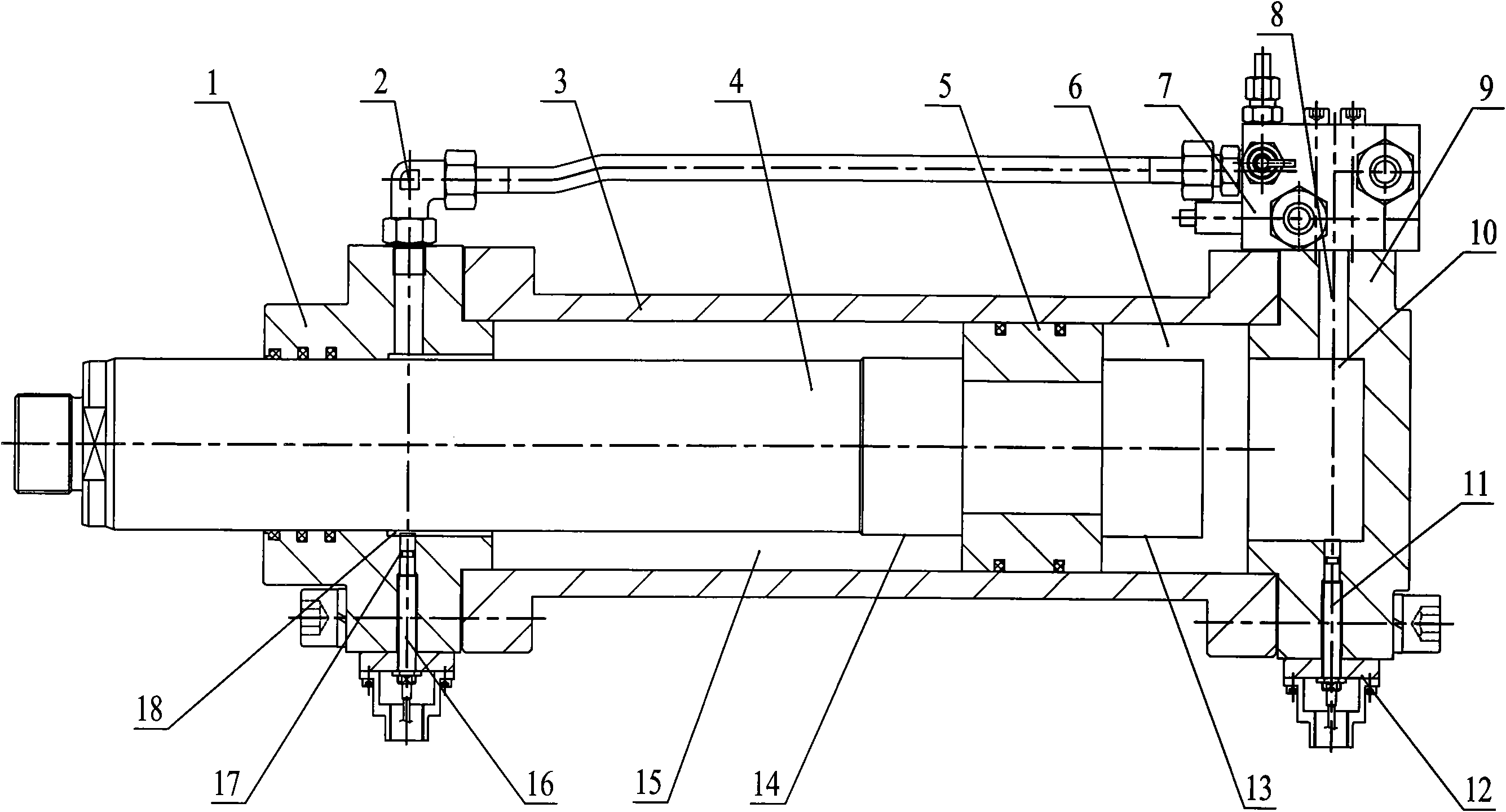

[0018] As shown in the figure: the short-range pressure-maintaining high-pressure heavy-duty hydraulic cylinder with a built-in second proximity switch in the embodiment is mainly composed of a cylinder head 1, a pipeline 2, a cylinder barrel 3, a piston rod 4, a piston 5, a functional valve block 7, The cylinder bottom 9, the second proximity switch 11, the protective cover 12, the first proximity switch 16 and other components are composed.

[0019] Such as figure 1 As shown, the piston rod 4 is assembled in the cylinder barrel 3, and the front and rear ends of the cylinder barrel 3 utilize screws and washers to install the cylinder head 1 and the cylinder bottom 8 respectively. The center of the cylinder head 1 is provided with a cylinder head through hole, and the piston rod 4 Through the through hole of the cylinder head, the piston rod 4 and the through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com