System for high-grade recycling waste heat of smoke discharged from boiler of power station

A power plant boiler, a high-grade technology, applied in the field of energy saving, can solve the problems of energy loss, difficulty in finding suitable heat users, low-pressure heater extraction and work ability, etc., and achieve the effect of high flue gas waste heat recovery temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

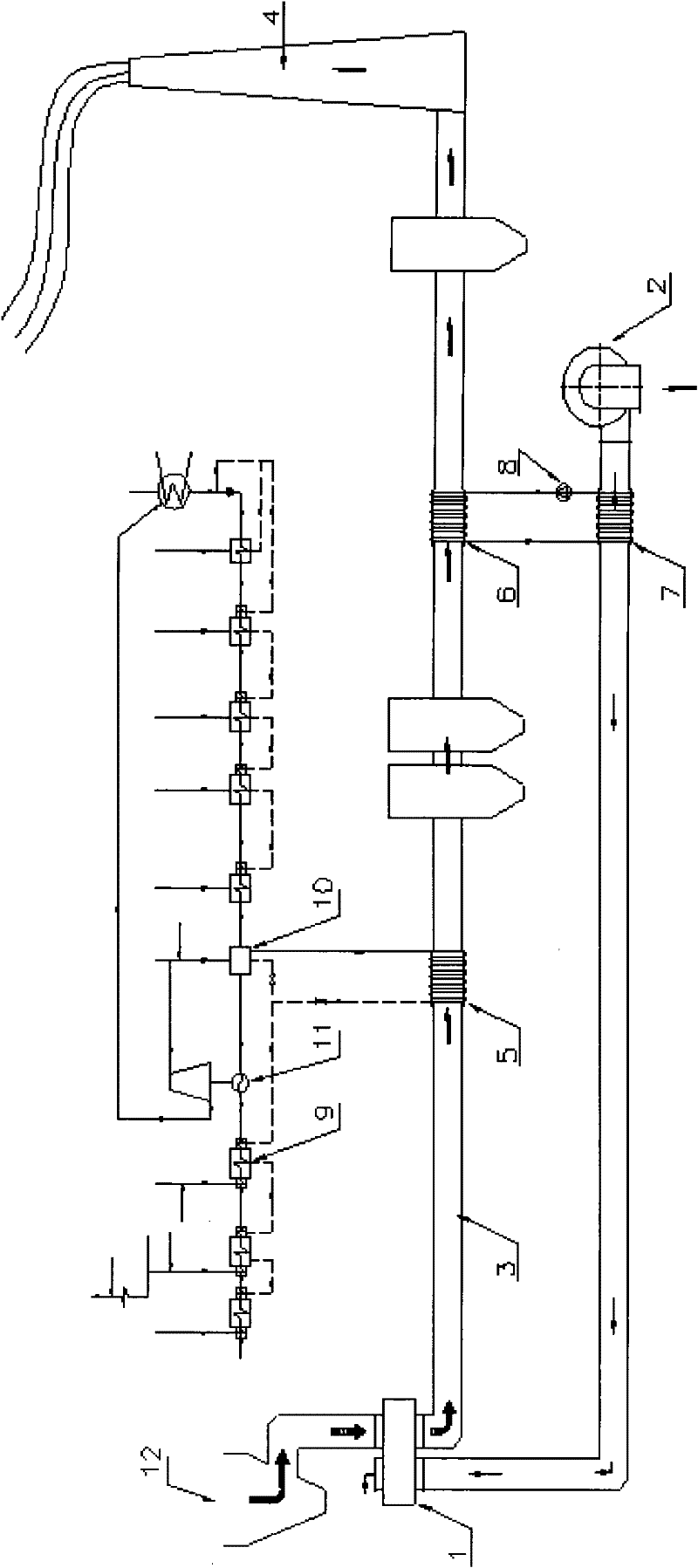

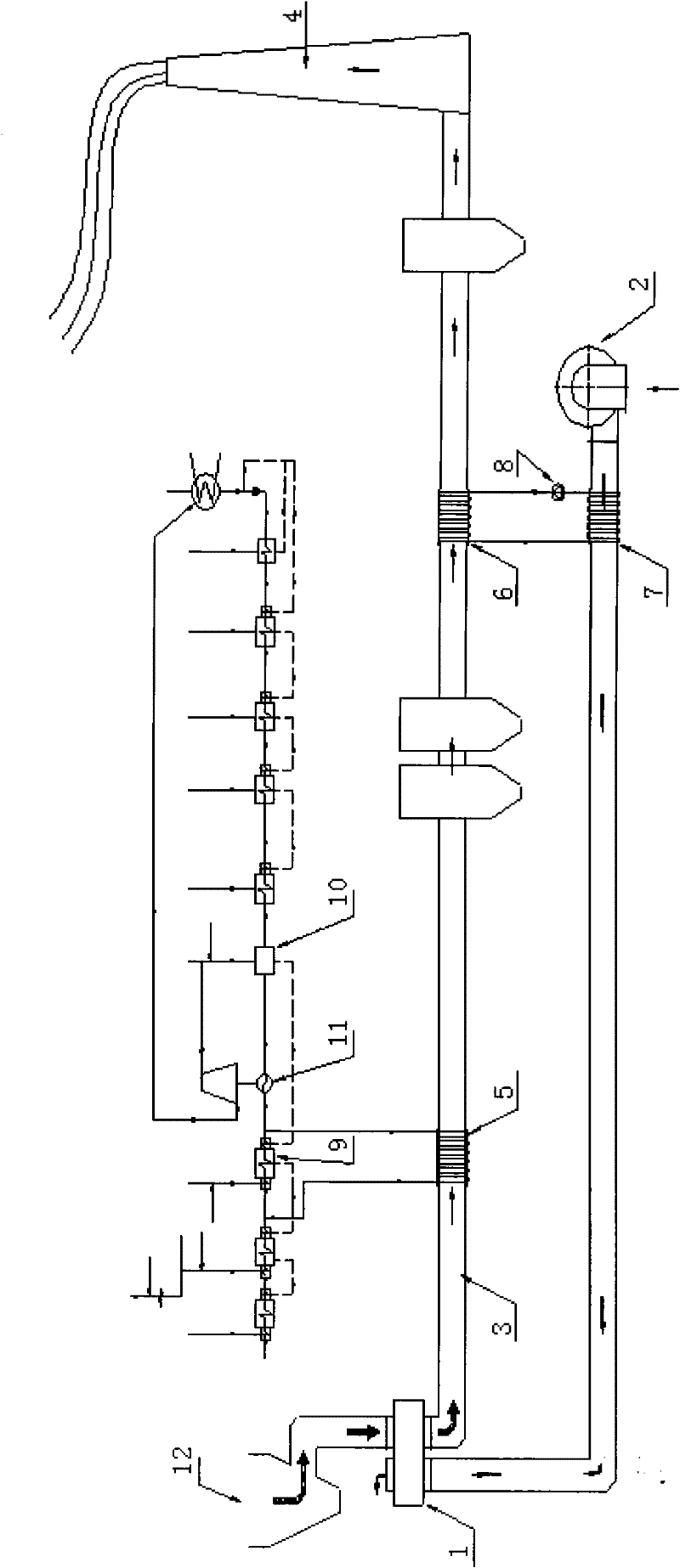

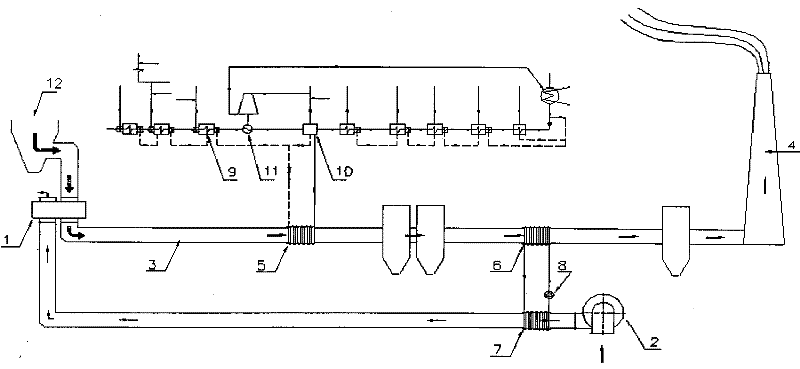

[0018] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes an air preheater 1 communicating with the flue gas outlet of the boiler 12 and an air blower 2 communicating with the air preheater 1. The flue gas outlet of the air preheater 1 communicates with the chimney 4 through a flue 3, and the flue 3 is installed with flue gas waste heat recovery secondary heat exchanger 5 and flue gas waste heat recovery primary heat exchanger 6 in sequence according to the direction of flue gas, and the connecting pipe between air blower 2 and air preheater 1 is equipped with air preheating primary exchanger Heater 7, air preheating primary heat exchanger 7, flue gas waste heat recovery primary heat exchanger 6 and primary circulating water pump group 8 form a closed water circulation circuit.

[0019] The air preheater primary heat exchanger 7, the primary side circulating water pump 8, and the flue gas waste heat recovery primary heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com