Refrigeration cycle system using propane as cooling medium

A circulation system and refrigerant technology, applied in refrigerators, refrigeration components, air-conditioning systems, etc., to achieve good environmental protection, not easy to leak, and good energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

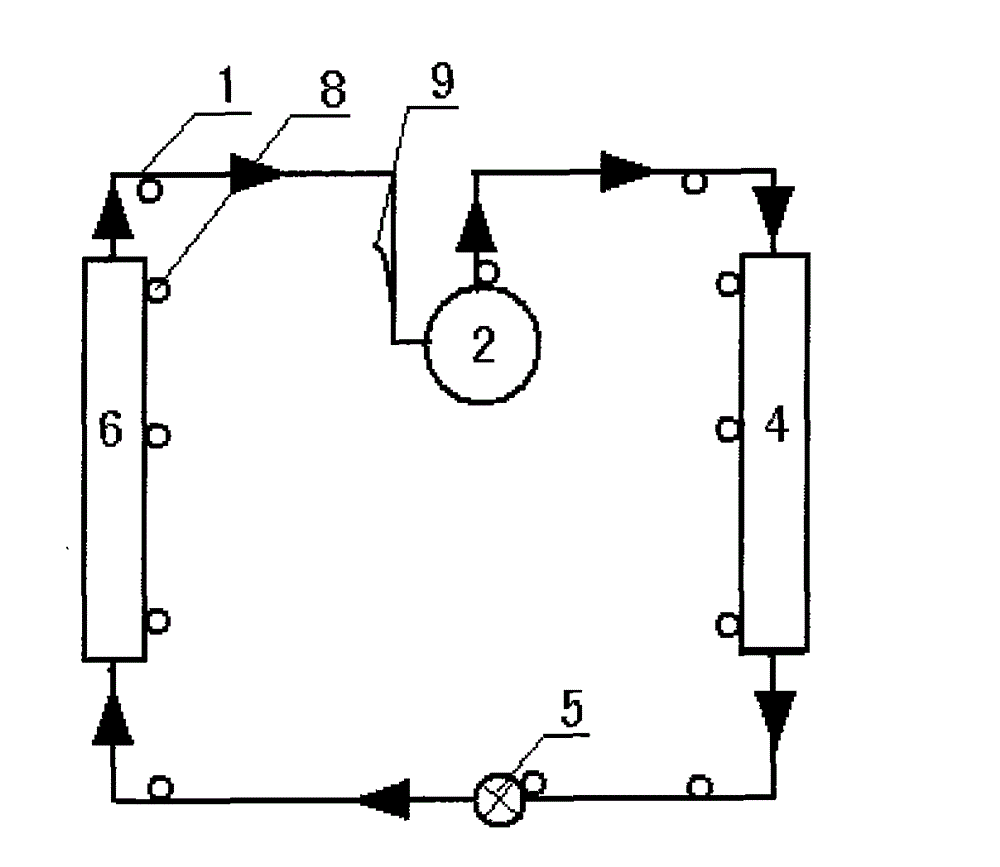

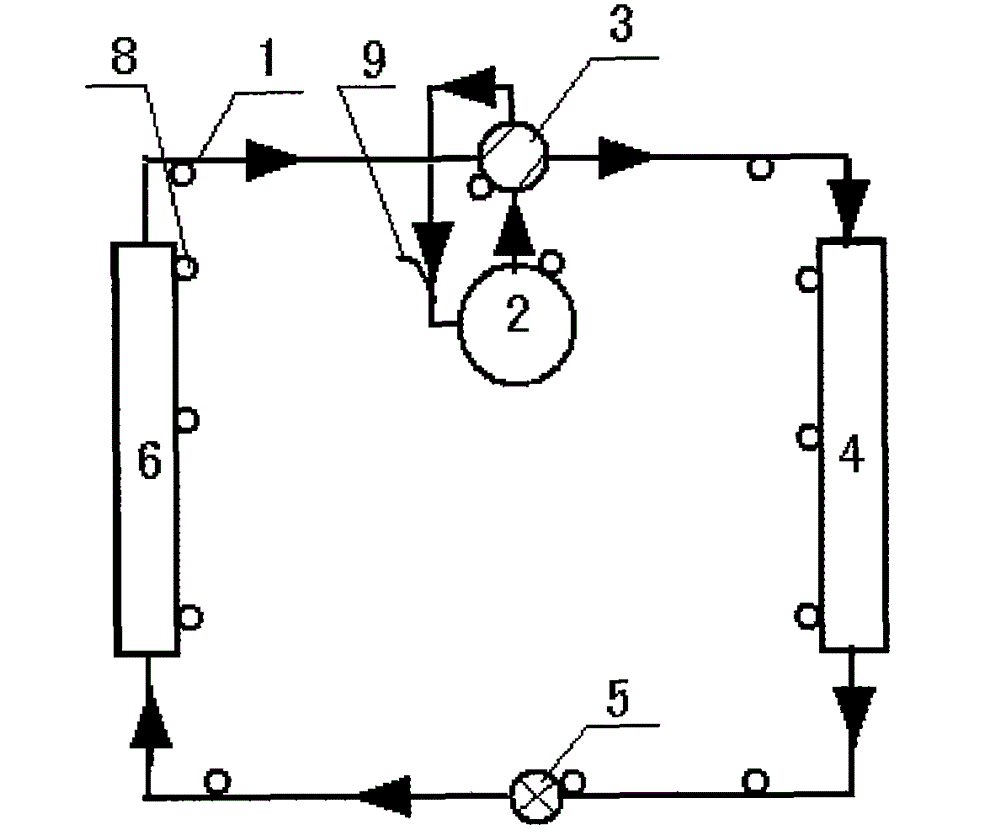

Embodiment 1

[0024] A refrigerating cycle system using propane (R290) as a refrigerant, which includes a compressor 2, a reversing valve 3, a condenser 4, an expansion valve 5, and an evaporator 6 connected in sequence via a pipeline 1. The cycle The system is divided into integral circulation system or split circulation system. In order to reduce the possibility of refrigerant leakage as much as possible, the air conditioner indoor unit, air conditioner outdoor unit and the pipeline 1 in the integral circulation system are made into one without intermediate The whole body with connectors, for example, is made into a window air conditioner. Also in order to minimize the possibility of refrigerant leakage, the indoor unit of the air conditioner in the split circulation system and the circulation pipeline 1 can be made into a middle without installation. There is a whole body with connectors, and there is only one connection joint between the pipeline 1 and the outdoor unit in the whole body....

Embodiment 2

[0026] On the basis of Example 1, the present invention can be provided with a quick-connect connector with good airtightness between the air-conditioning indoor unit in the split circulation system and the circulation pipeline 1, and this joint also has good Excellent sealing, because it is a quick-connect plug-and-connect refrigerant leakage is very small during the plug-in process.

Embodiment 3

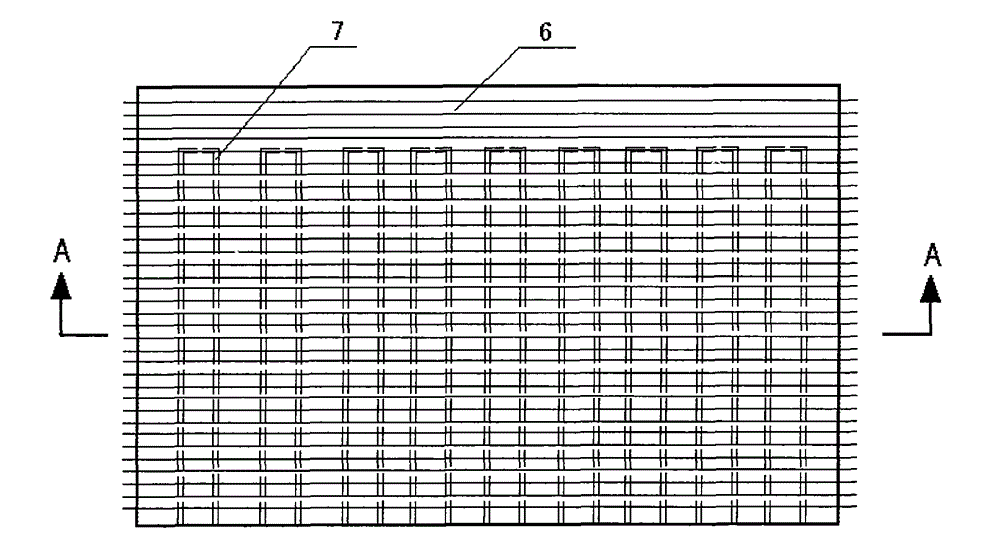

[0028] On the basis of Embodiment 1 or 2, in order to minimize the amount of refrigerant used in the present invention, the outer diameter of the U-shaped tube inside the condenser or evaporator is 5mm-7mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com