Optical fiber Bragg grating pressure sensor and corresponding measurement method thereof

An optical fiber Bragg and pressure sensor technology, which is applied in the measurement of fluid pressure using optical methods, and the measurement of force by measuring the change of optical properties of materials when they are stressed, can solve the problems of temperature cross-sensitivity and difficulty in accurately measuring pressure, etc. Achieve the effect of easy operation, solve temperature cross-sensitivity, and improve measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

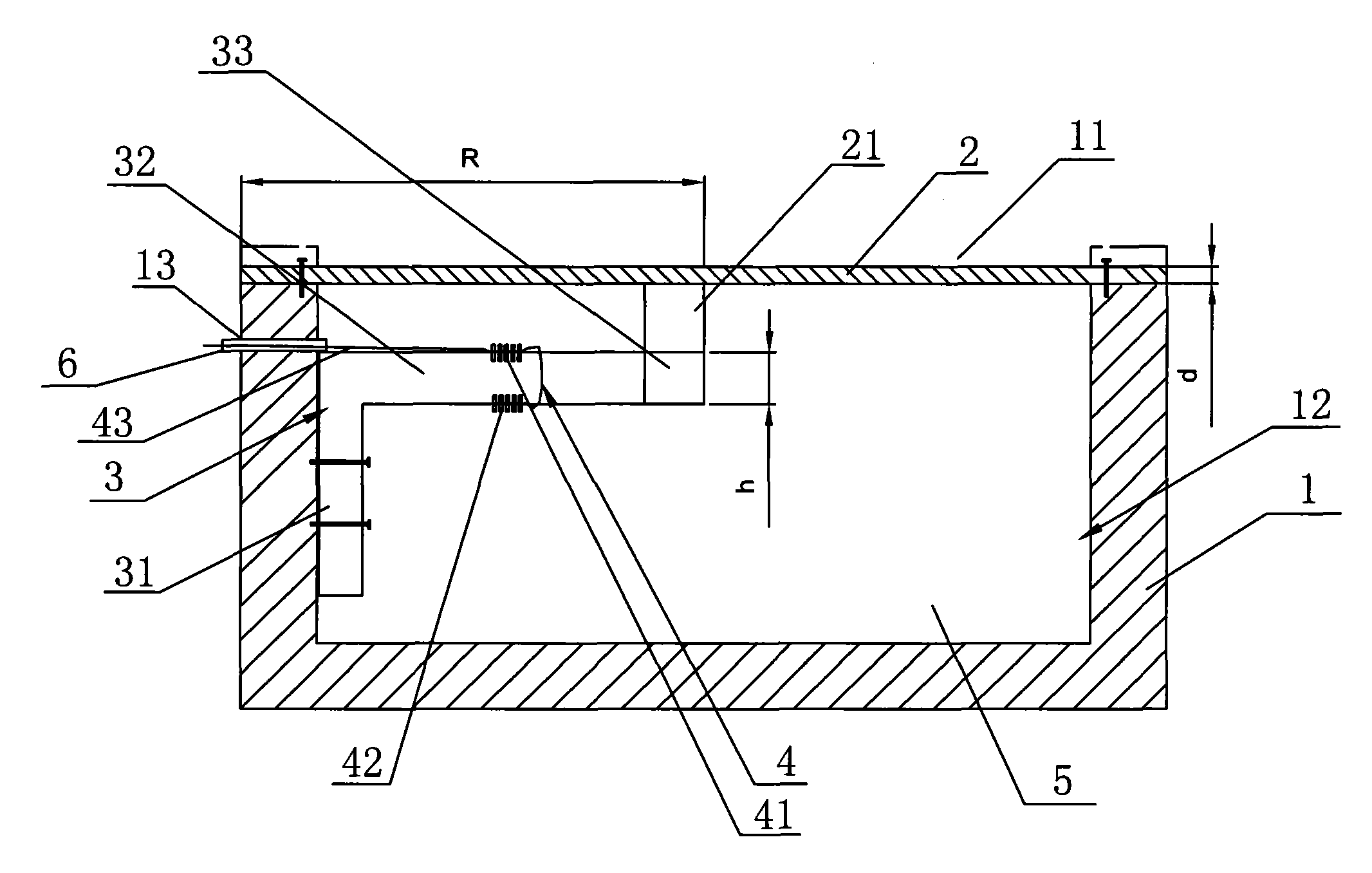

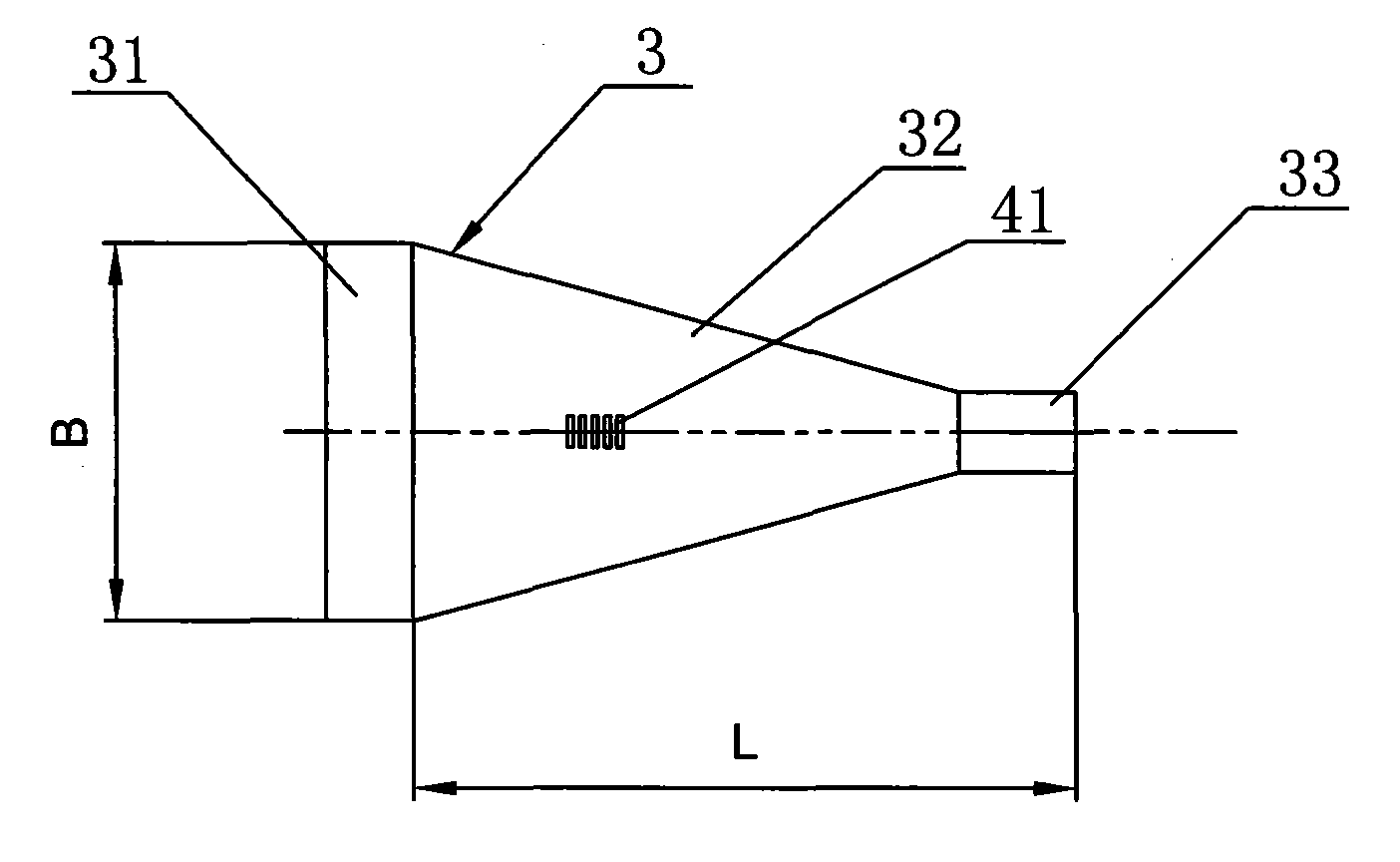

[0033] A kind of fiber Bragg grating pressure sensor that the present invention proposes, such as figure 1 and figure 2As shown, it includes a cylindrical housing 1, a circular elastic diaphragm 2, an L-shaped equal-intensity beam 3 and a fiber Bragg grating 4. An opening 11 is arranged on the top of the housing 1, and the opening 11 is connected to the housing. The internal space of 1 is connected to form a cavity 12 with an opening, the elastic diaphragm 2 is connected to the top of the housing 1, the elastic diaphragm 2 covers the opening 11, and the L-shaped equal-strength beam 3 is arranged in the cavity 12, L The fixed plate 31 of the equal-strength beam 3 can be fixedly connected with the cavity wall of the cavity 12 by fasteners such as screws, and the free end of the beam arm 32 of the L-shaped equal-strength beam 3 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com