Method for manufacturing selective emitter solar cell

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as complicated processes and increased costs, and achieve the goals of improving conversion efficiency, reducing contact resistance, and inhibiting surface recombination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and easy to understand, below in conjunction with preferred embodiments of the present invention, describe in detail as follows:

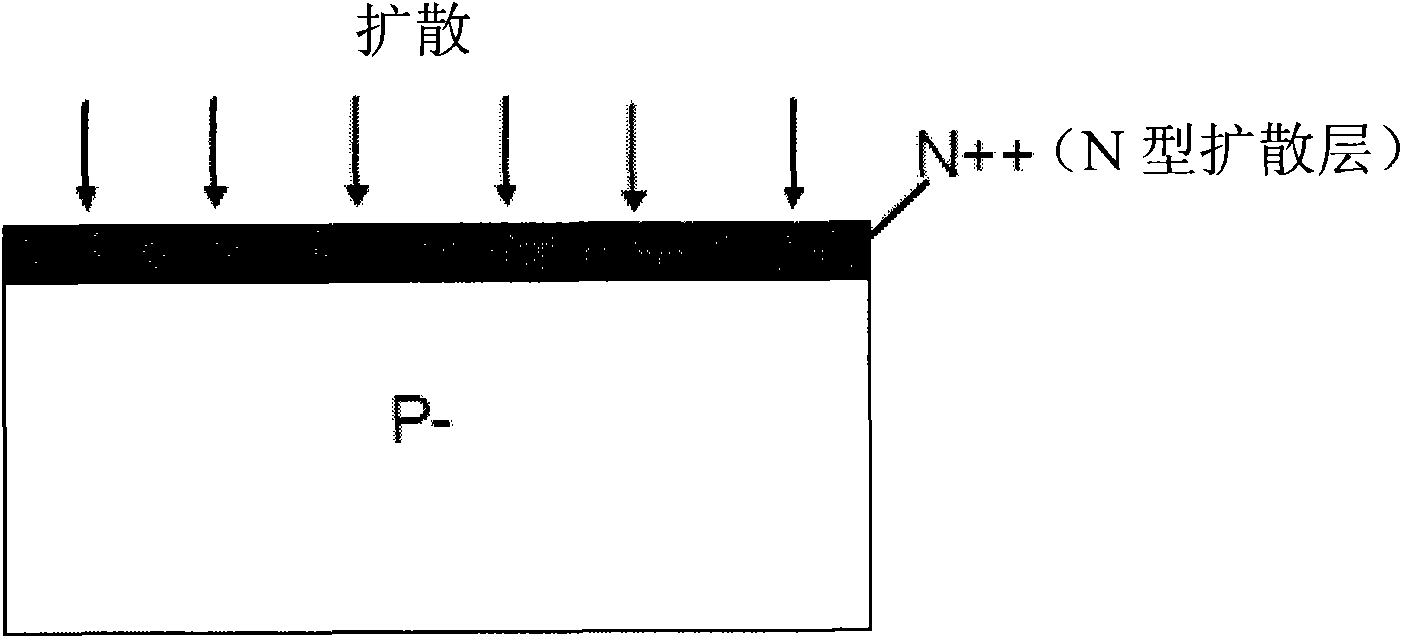

[0020] Step 1: Coating a slurry containing N-type impurities on the P-type substrate for thermal diffusion or performing gas phase diffusion on the P-type substrate to form a higher concentration N-type diffusion layer.

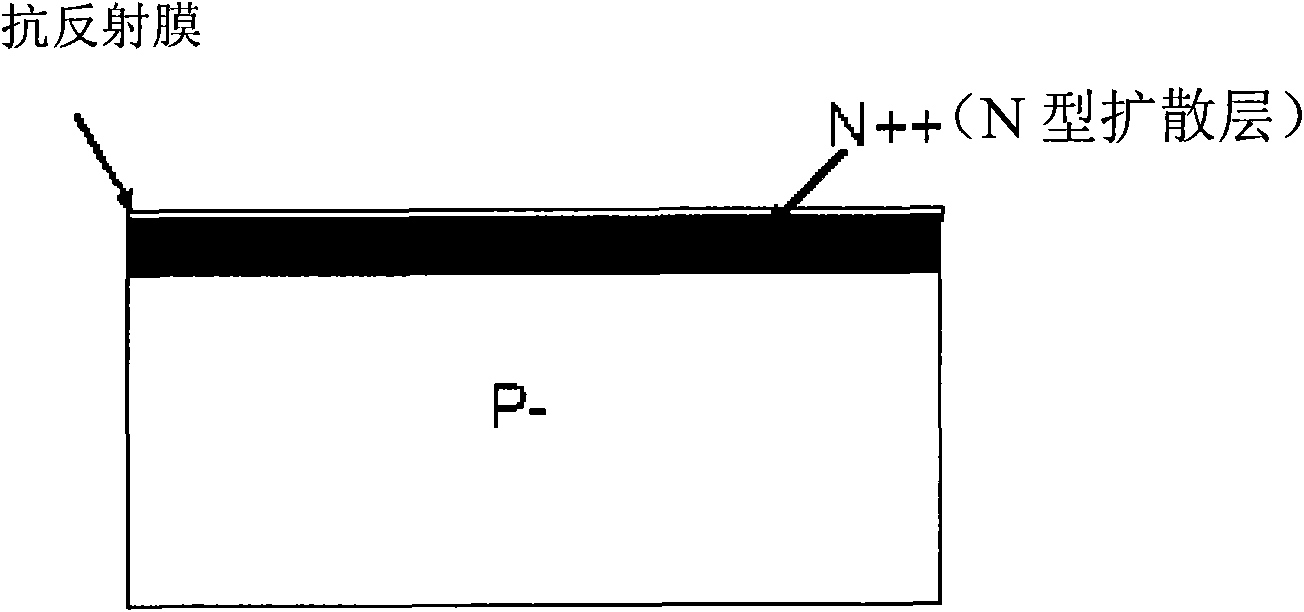

[0021] Step 2: On the light-receiving surface, use a printing plate with a comb-like electrode pattern such as a screen printing device to print silver electrodes and dry them. This electrode is located on the subsequently formed high-concentration emitter layer, generally about 80um.

[0022] Step 3: Implanting P-type impurities after the electrodes on the light-receiving surface are formed. Under the blocking effect of the electrode, there is no P-type impurity implanted under the electrode, so a high N-type diffu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com