Aluminum alloy anode material for battery and manufacturing method thereof

A technology of anode material and manufacturing method, applied in the field of aluminum alloy anode material for battery and its manufacture, and anode material for battery, can solve the problem of unsatisfactory properties such as open circuit potential, working potential, actual capacity current efficiency and surface dissolution state, etc. problems, to achieve excellent electrochemical performance, improve utilization, and weaken the effects of electrochemical polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

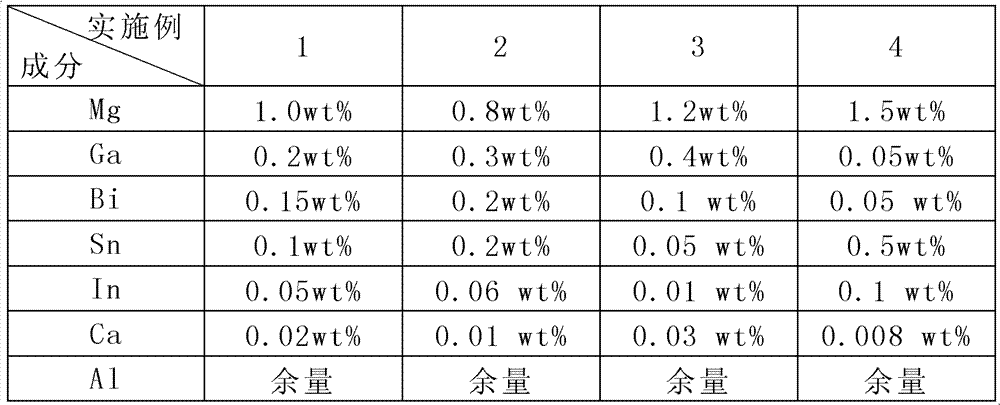

[0037] According to the composition of Example 1 mass percentage in Table 1, the aluminum ingot is first added to the graphite crucible and melted in a resistance furnace. When the temperature of the melt is 660 ° C, metal Sn is added. After the melt is refined, the temperature is 730 ° C. Add other alloying elements under certain conditions, stir thoroughly with a graphite rod after the metal Mg is completely melted, add hexachloroethane to remove slag, pass in argon to degas, the argon pressure is 0.1MPa, and the ventilation time is 3-5 minutes. After degassing and slag removal, let stand for 1-5 minutes, and cast into flat ingots.

[0038] The cast flat ingot was uniformly annealed at a temperature of 550°C for 120 minutes, water-cooled, and after face milling, the aluminum alloy flat ingot was cold-rolled at a temperature of 200°C to a finished aluminum alloy anode material with a thickness of 0.5mm.

Embodiment 2

[0040] Dosing according to the composition of Example 2 in Table 1 by mass percentage, first put the aluminum ingot into the graphite crucible and melt it in a resistance furnace, when the temperature of the melt is 680°C, add metal Sn, and after the melt is refined, heat it at a temperature of 750°C Add other alloying elements under certain conditions, stir thoroughly with a graphite rod after the metal Mg is completely melted, add hexachloroethane to remove slag, pass in argon to degas, the argon pressure is 0.05MPa, and the ventilation time is 3-5 minutes. After degassing and slag removal, let stand for 1-5 minutes, and cast into flat ingots.

[0041] The cast flat ingot was uniformly annealed at a temperature of 560°C for 60 minutes, water-cooled, and after face milling, the aluminum alloy flat ingot was cold-rolled at a temperature of 180°C to a finished aluminum alloy anode material with a thickness of 0.6 mm.

Embodiment 3

[0043] According to the composition of Example 3 mass percentage in Table 1, the aluminum ingot is first added to the graphite crucible and melted in a resistance furnace. When the temperature of the melt is 670 ° C, metal Sn is added. Add other alloying elements under certain conditions, stir thoroughly with a graphite rod after metal Mg is completely melted, add hexachloroethane to remove slag, pass in argon to degas, the argon pressure is 0.2MPa, and the ventilation time is 3-5 minutes. After degassing and slag removal, let stand for 1-5 minutes, and cast into flat ingots.

[0044] The cast flat ingot was uniformly annealed at a temperature of 530°C for 180 minutes, water-cooled, and after face milling, the aluminum alloy flat ingot was cold-rolled at a temperature of 220°C to a finished aluminum alloy anode material with a thickness of 0.4mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com