Floor non-contact power supply device of lift car

An elevator car, non-contact technology, applied in the direction of circuit devices, electrical components, electromagnetic wave systems, etc., can solve problems such as easy fires, and achieve the effects of avoiding eddy current heating and fire hazards, and avoiding conductor breakage and insulation aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

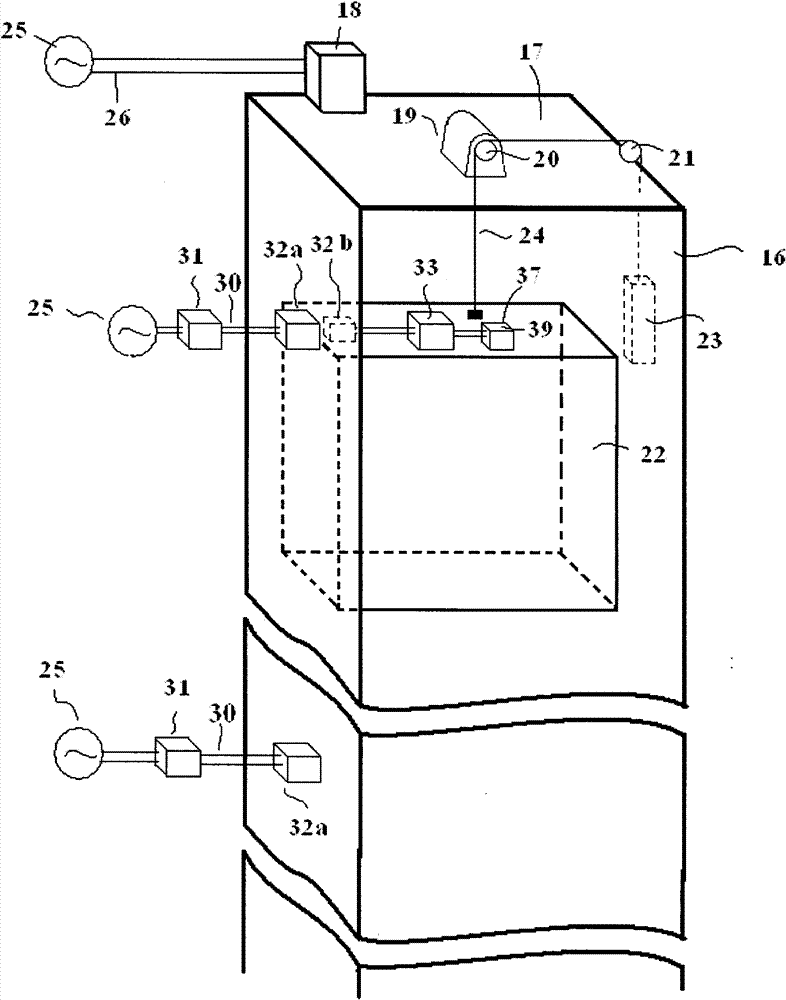

[0027] figure 1 It is a schematic diagram of main parts of Embodiment 1 of the floor-by-floor non-contact power supply device for elevator cars of the present invention.

[0028] The top 17 of the elevator hoistway 16 in buildings such as buildings is equipped with control cabinet 18 and winch 19; On the main pulley 20 and secondary pulley 21 of winch 19, hang with main wire rope 24, and one end of main wire rope 24 is the elevator car The other end of 22 is a counterweight 23; the three-phase industrial frequency power supply 25 supplies electric energy to the control cabinet 18 through the power transmission cable 26; The operation specified for the destination station shows the centralized control system. This is the driving signal of the elevator car.

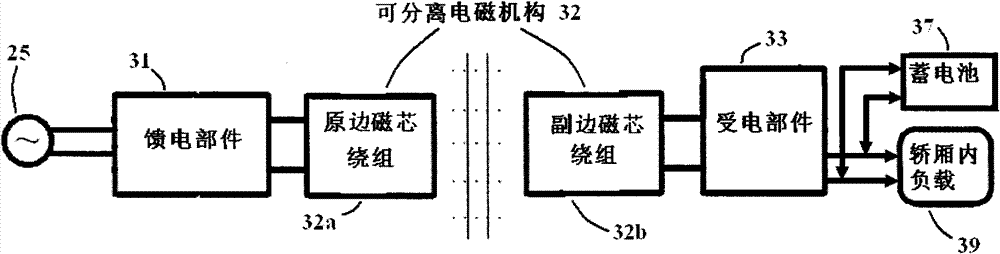

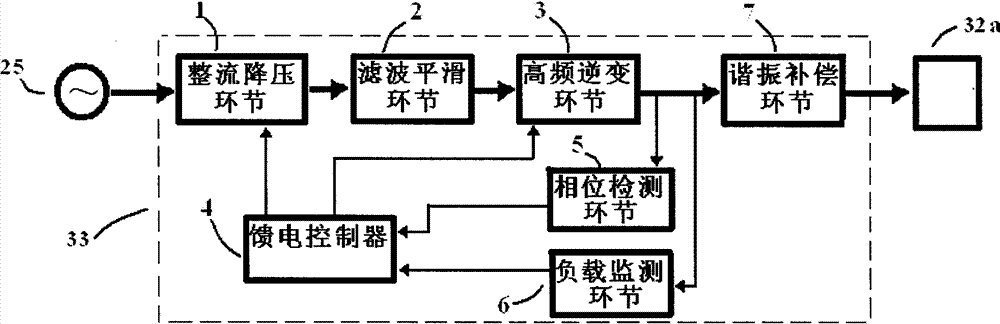

[0029] The invention solves the non-contact power supply of the load in the car by floor, figure 1 The middle feeding part 31 is connected between the commercial frequency power supply 25 and the detachable electromagnet...

Embodiment approach 2

[0034] Fig. 5 is a schematic diagram of main parts of an elevator system of an elevator car floor-by-floor non-contact power supply device according to Embodiment 2 of the present invention. and figure 1 In the elevator car according to Embodiment 1 shown, the parts that are the same as the non-contact power supply devices for each floor are denoted by the same reference numerals, and descriptions of overlapping parts are omitted. In addition, other parts because of the Figure 2 to Figure 4 The same, so its description is also omitted.

[0035] In the floor-by-floor non-contact power supply device for elevator cars in Embodiment 2, there may be only one power feeding part 31 in the whole device, and the detachable electromagnetic mechanisms on all floors are fed by it in time division. Like this, because the distance from the feeder part 31 to the separable electromagnetic mechanism 32 of each floor is inconsistent, the connecting line has an inconsistent inductance (the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com