Hybrid system control method

A technology of a hybrid system and control method, applied in the control device, engine control, transmission control and other directions, can solve the problem of no solution, unavoidable torque drop, etc., and achieve the effect of preventing torque drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Embodiments of the present invention will be described below with reference to the accompanying drawings.

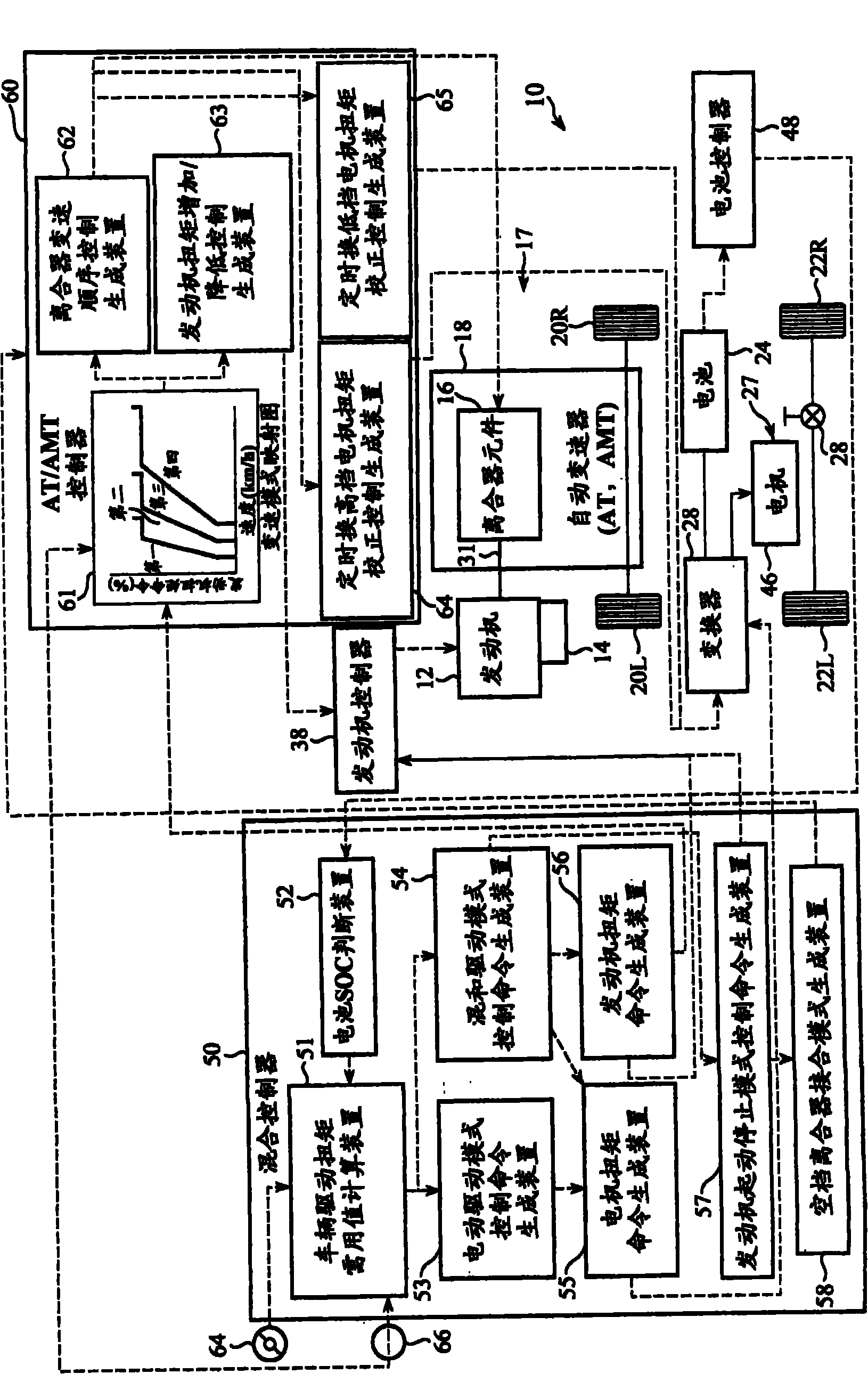

[0056] exist figure 1 In , a vehicle 10 to which the hybrid system control method belonging to the first embodiment of the present invention is applied and a control system of the vehicle 10 capable of realizing the control of the hybrid system are shown. The vehicle 10 is a four-wheel drive hybrid vehicle in which the electric drive axle unit is arranged on the driven axle of an existing two-wheel drive vehicle so as to be constructed with minimal vehicle modification, and the vehicle 10 is equipped with an internal combustion engine 12 for starting The starter motor 14 of the engine 12, the first drive system 17 for transmitting the drive force of the internal combustion engine to the shafts of the front wheels 20L and 20R, the battery 24, and the first drive system for supplying electric drive power to the shafts of the rear wheels 22L and 22R Two drive systems ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com