Permanent magnet motor and refrigeration compressor

A permanent magnet motor and magnetic tile technology, applied in the field of permanent magnet motors and refrigeration compressors, can solve the problems of unstable compressor speed, large compressor jitter, and large speed fluctuations, and reduce the torque fluctuation amplitude. , Improve the power density and ensure the effect of stability

Inactive Publication Date: 2021-01-26

QINGDAO WANBAO COMPRESSOR

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Existing refrigeration compressors mostly use 6-pole, 9-slot and 4-pole, 6-slot motors, the stator teeth of which are evenly distributed, and the winding is a concentrated double-layer winding. The inventor found that the torque ripple of this type of motor is large at low speed , so that the speed of the compressor is unstable during operation, and the speed fluctuates greatly, resulting in a large vibration of the compressor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0042] This embodiment discloses a refrigeration compressor, which is installed with the permanent magnet motor described in Embodiment 1. Other structures of the refrigeration compressor adopt existing structures, and will not be described in detail here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

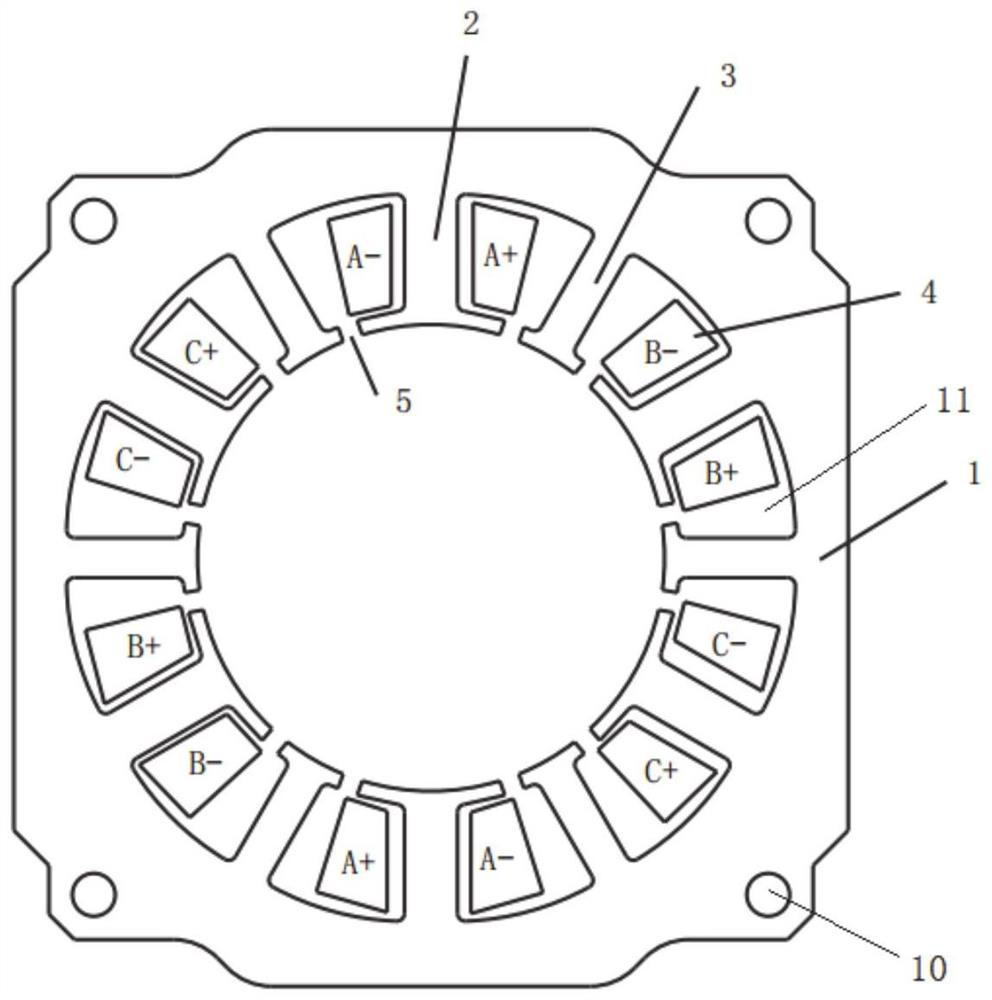

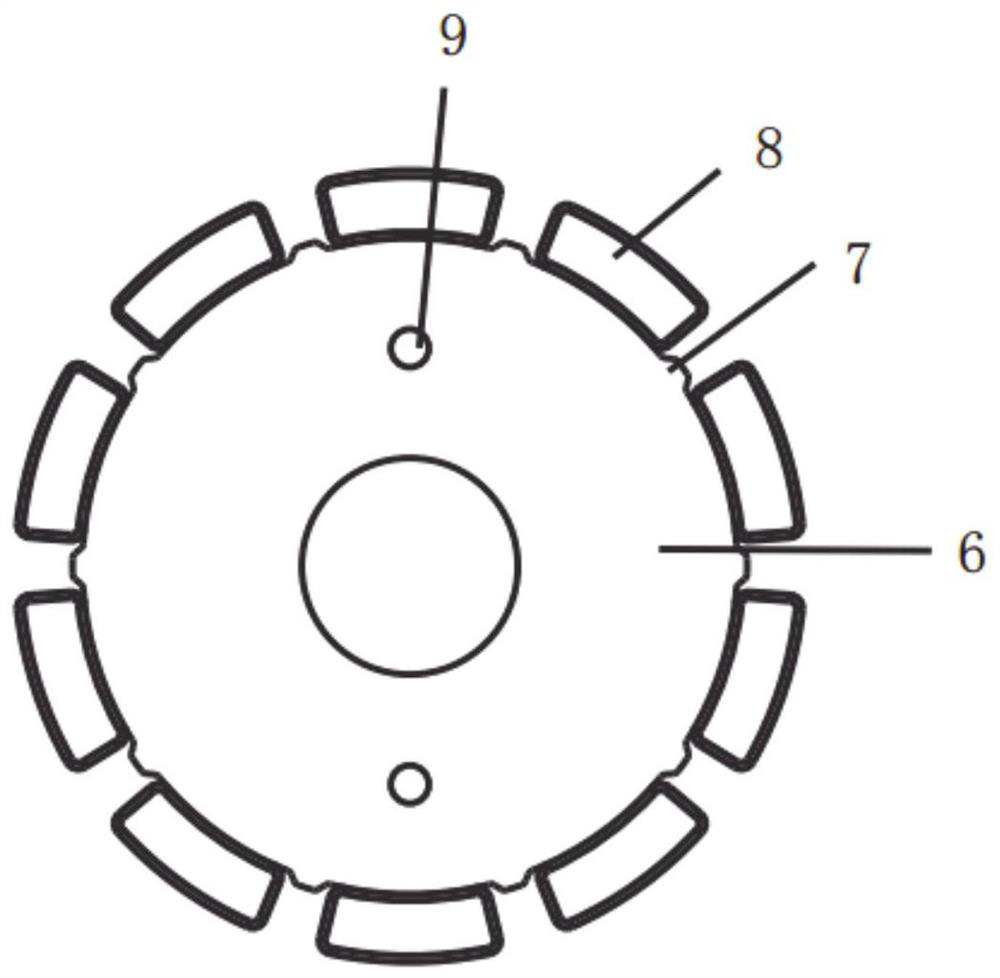

The invention relates to a permanent magnet motor and a refrigeration compressor. The permanent magnet motor comprises a stator and a rotor located in the stator, and is characterized in that the stator comprises a stator yoke part, armature teeth and auxiliary teeth are alternately arranged on the inner side face of the stator yoke part along the circumference, the width of the armature teeth islarger than that of the auxiliary teeth, and tooth grooves are formed between the armature teeth and the auxiliary teeth; the armature teeth are wound with a three-phase winding, the rotor comprises arotor core, the outer peripheral surface of the rotor core is provided with a plurality of magnetic shoes, and the permanent magnet motor is small in torque fluctuation amplitude and stable in rotating speed.

Description

technical field [0001] The invention relates to the technical field of motor equipment, in particular to a permanent magnet motor and a refrigeration compressor. Background technique [0002] The statements herein merely provide background information related to the present invention and do not necessarily constitute prior art. [0003] At present, with the implementation of the new national standard, refrigerator manufacturers often use low speed when conducting power consumption tests. Noise also puts forward higher requirements. [0004] Existing refrigeration compressors mostly use 6-pole, 9-slot and 4-pole, 6-slot motors, the stator teeth of which are evenly distributed, and the winding is a concentrated double-layer winding. The inventor found that the torque ripple of this type of motor is large at low speed , so that the speed of the compressor is unstable during operation, and the speed fluctuates greatly, resulting in a large vibration of the compressor. Conten...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02K1/12H02K1/16H02K1/27H02K3/12H02K3/28H02K29/03

CPCH02K1/12H02K1/16H02K1/165H02K1/2706H02K3/12H02K3/28H02K29/03H02K2213/03

Inventor 罗欢赵新华王燕霞王泽宇戴照强

Owner QINGDAO WANBAO COMPRESSOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com