Water curing method and device for centrifuged pretensioned prestressed concrete pipe pile

A technology for concrete pipe piles and water maintenance, which is applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of affecting benefits, wasting water resources, and large heat loss, reducing maintenance costs, saving costs, and realizing reuse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A water curing method for pretensioned prestressed concrete pipe piles after centrifugation:

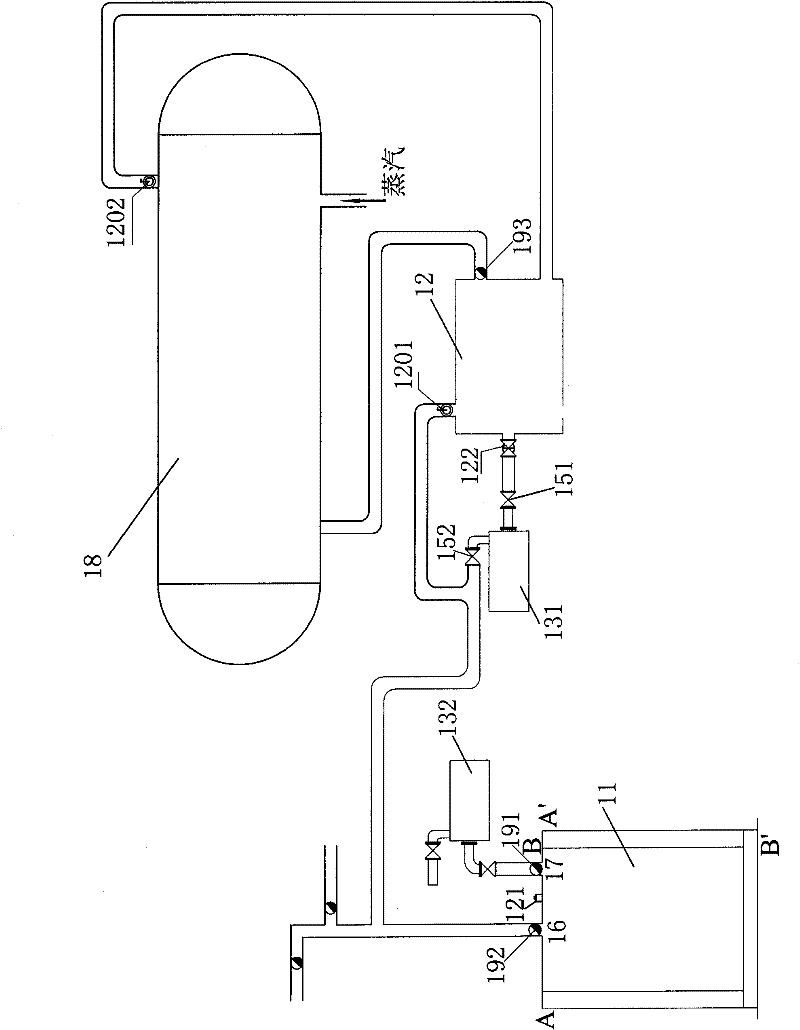

[0026] Step 1) Set up an autoclave condensed water recovery and residual steam heating water storage tank 12, and introduce the condensed water and residual steam in the autoclave 18 into the autoclave condensed water recovery and residual steam heating water storage tank 12;

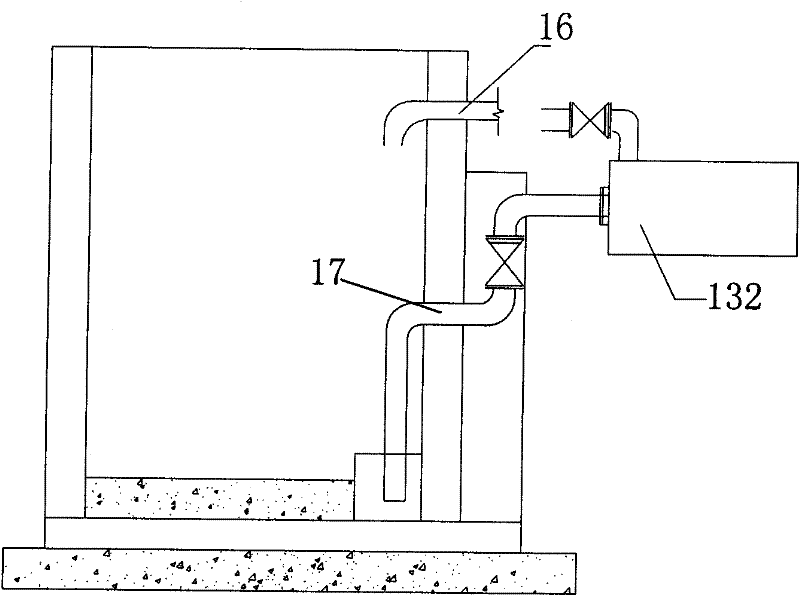

[0027] Step 2) Put the centrifuged strip steel molded pipe pile into the steam curing pool 11, and after the strip steel molded pipe pile is filled with the steam curing pool 11, open the first electric control valve 191 at the water inlet 16 of the steam curing pool 11 , the condensed water in the autoclave is recovered and the condensed water in the residual steam heating water storage tank 12 is introduced into the steam curing pool 11 and this water is used as the curing water. After the curing water is immersed in the entire steel mold, the steam curing cover is covered, and then the Still condense...

Embodiment 2

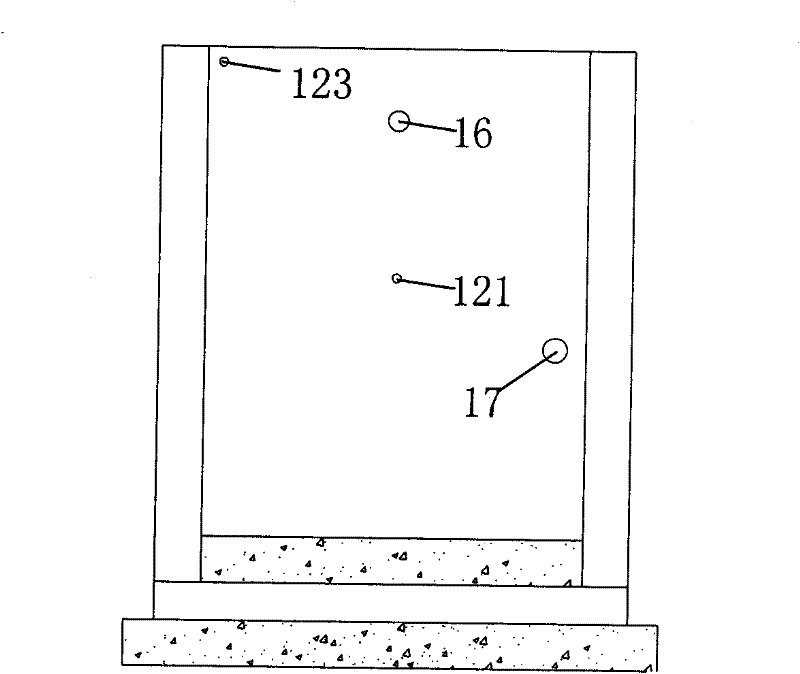

[0031]A water curing device for implementing the water curing method after the pretensioning prestressed concrete pipe pile is centrifuged, comprising: a steam curing pool 11, in which a water-air port 16 and a hot water outlet 17 are arranged, the The maintenance device also includes an autoclave condensed water recovery and residual steam heating water storage tank 12 and an autoclave 18, and the autoclave condensed water recovery and residual steam heating water storage tank 12 is provided with a residual steam outlet, a residual steam inlet, and a condensed water Outlet and condensed water inlet, on autoclave 18, be provided with steam inlet and steam outlet, between the water-air port of described autoclave 11 and the condensed water outlet of autoclave condensed water recovery and residual steam heating water storage tank 12 A condensed water passage is provided between the water-air port of the steam culture tank 11 and the steam outlet of the autoclave condensed water r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com